0 maintenance requirements (cont'd) – Reznor MAPSII Series REDA Users Manual User Manual

Page 4

Form O-MAPS II, P/N 209179 R7, Page 4

WARNING: Turn off the power before performing all maintenance procedures (except to

check refrigerant pressure and temperature). Lock disconnect switch in OFF position. If the

system has a heat section, when you turn off the power supply, turn off the gas. See Hazard

Levels, page 3.

NOTE: If replacement parts are required, use only factory-authorized parts.

For information, call 800-695-1901 or go to www.RezSpec.com

Models RDCA & RDDA with a gas-fired heat section (beginning of the

heating season) - See Paragraph 9.:

NOTE: If equipped with an optional Model JHUP curb duct furnace,

these same maintenance procedures apply to the duct furnace.

Clean all dirt and grease from the combustion air openings and venter

assembly.

Check the burner and heat exchanger for scale, dust, or lint accumulation.

Clean as needed.

Check the gas valves to ensure that gas flow is being shutoff completely.

Models RECA & REDA with an electric heat section (beginning of the

heating season) - See Paragraph 10.

Check the wiring connections.

Check the heat section and elements for dust or lint accumulation. Care-

fully clean as needed.

2.0 Maintenance

Requirements

(cont'd)

Maintenance

Schedule (cont'd)

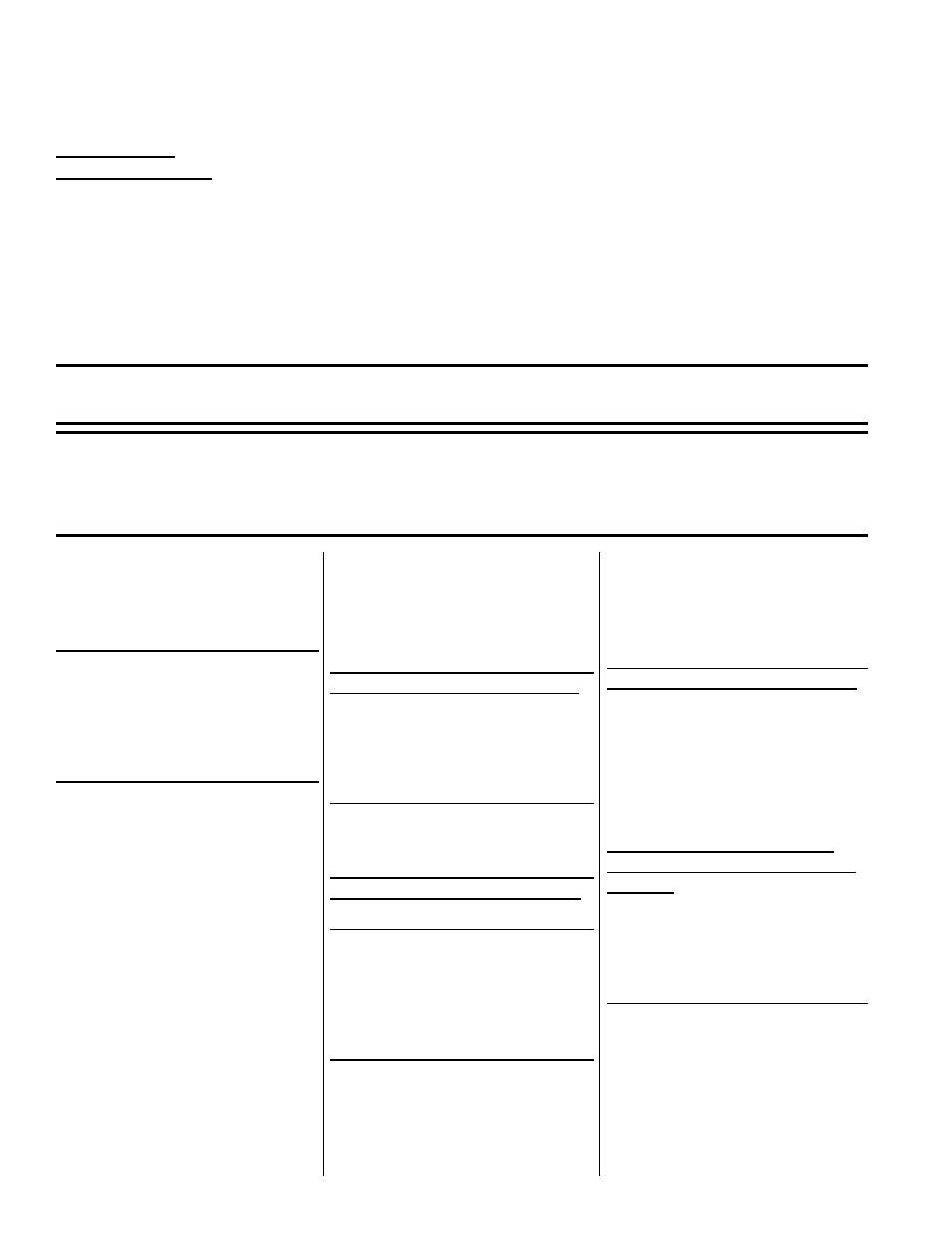

TUBING SECTION

• Low Refrigerant Pressure Cutouts

• High Refrigerant Pressure Cutouts

• Filter Driers

• Liquid Line Service Gauge Ports

COMPRESSOR SECTION

• Ckt A Compressor

• Ckt B Compressor

• Ckt C Compressor

• Discharge & Suction Service Ports

• Optional Hot Gas Bypass Valve(s)

HIGH VOLTAGE ELECTRICAL

COMPARTMENT

1) Blower Motor Contactor or Starter

2) Control Transformers (as required)

3) Dehumidification Compressor

Contactor (RDA, RDDA, REDA)

4) Condenser/Compressor Contactor

5) Optional Phase Loss/Phase Rever-

sal Control (optional beginning

10/05; standard prior to 10/05)

6) Optional Damper Motor

Transformer

7) Optional Over/Under Voltage

Control

8A&B) Condenser Motor Capacitors

9) Optional Convenience Outlet

(requires separate supply line)

AUXILIARY COMPARTMENT

10) Digital Controller (FX05 or FX06)

• Optional Damper Motor

• Outside Air Relative Humid-

ity Transmitter (Std RDA/

RDDA/REDA; Optional

RCA/RDCA/RECA)

Models RDCA & RDDA With Gas

Heat Section (FIGURE 1A only):

21) Venter Assembly

22) Single-Stage Gas Valves

23) Optional Modulating Gas Valve

24) Optional Low Gas pressure

Switch

25) Optional High Gas Pressure

Switch

Models RECA & REDA With

Electric Heat Section (FIGURE

1B only):

26) Fuse Block/Fuses

27) Contactor

28) Low Voltage Terminals

29) Manual Reset Limit

30) Auto Reset Limit

FIELD INSTALLED

• Discharge Air Sensor (supply duct)

• Optional Return Air Firestat (duct)

• Optional Discharge Air Firestat

(duct)

• Optional Smoke Detector (duct)

• Optional wall-mounted controls

11) Air Proving Pressure Switch

12&13) Optional Control Relays

14) Optional Dirty Filter Switch

15) Optional Time Clock or BAS Card

16) Humidity Input Converter

Models RDCA & RDDA With Gas

Heat Section (FIGURE 20 only):

17) Combustion Air Pressure Switch

18) Ignition Control

19) Optional Power Signal Converter

20) Venter Motor Capacitor (line

voltage)

BLOWER SECTION

• Blower Motor

Models RDCA & RDDA With Gas

Heat Section (FIGURE 1A only):

• Limit Control (capillary type)

COIL SECTION

• Evaporator Coils

• Thermal Expansion Valves

• Froststat (one per cooling circuit)

• Optional Subcooling Valves

(RCA/RDCA/RECA)

FILTER AND INLET AIR

SECTION

• Inlet Air, Humidity, & Override

Sensors

• Ckt D or Dh Compressor