2 venting – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 9

Form I-RP/HRPD, P/N 132210 R14, Page 9

For Propane: When the heater leaves the factory, the combination valve is set so that

the outlet gas pressure of a single-stage valve or high fire of a two-stage valve is 10"

w.c. Low fire on a two-stage valve is set to 5" w.c. Inlet pressure to the valve must be

a minimum of 11" w.c. and a maximum of 14" w.c.

Before attempting to measure or adjust manifold gas pressure, the inlet (supply) pres-

sure must be within the specified range for the gas being used both when the heater is

in operation and on standby. Incorrect inlet pressure could cause excessive manifold

gas pressure immediately or at some future time.

Instructions to Check Valve Outlet (Manifold) Pressure:

CAUTION: DO NOT bottom out the gas valve regulator adjusting screw. This can

result in unregulated manifold pressure causing overfire and heat exchanger

failure.

1) With the manual valve (on the combination valve) positioned to prevent flow to the

main burners, connect a manometer to the 1/8" pipe outlet pressure tap in the valve.

NOTE: A manometer (fluid-filled gauge) is recommended rather than a spring type

gauge due to the difficulty of maintaining calibration of a spring type gauge.

2) Open the valve and operate the heater. Measure the gas pressure to the manifold.

To measure the low stage pressure on units equipped with a two-stage valve, discon-

nect the wire from the "HI" terminal on the valve. (Be sure to reconnect the wire.)

Normally adjustments should not be necessary to the factory preset regulator. If adjust-

ment is necessary, set pressure to correct settings by turning the regulator screw IN

(clockwise) to increase pressure. Turn regulator screw OUT (counterclockwise) to

decrease pressure. Consult the valve manufacturer's literature provided with the fur-

nace for more detailed information.

6.2 Venting

Locate power-vented furnaces so that flue discharge is not directed at fresh air inlets.

The flue discharge openings are located on the side of the furnace just above the con-

trol access panel. The position of this opening discourages recirculation of combustion

products and provides for furnace operation in all normal weather conditions.

Optional Vertical Flue

Discharge (Option

CC3)

These power vented furnaces are certified with four feet of vertical pipe attached as

shown in

FIGURES 5A and 5B. The distance is measured from the top of the unit to

the bottom of the vent cap. The option package includes the 5" vent cap, the adapter

assembly and the seal plate. The vent pipe and supports are field supplied.

Optional vertical vent piping provides compliance with local codes that require either

10-ft horizontal or 4-ft vertical clearance between the flue outlet and fresh air intake of

the heating system and/or the building.

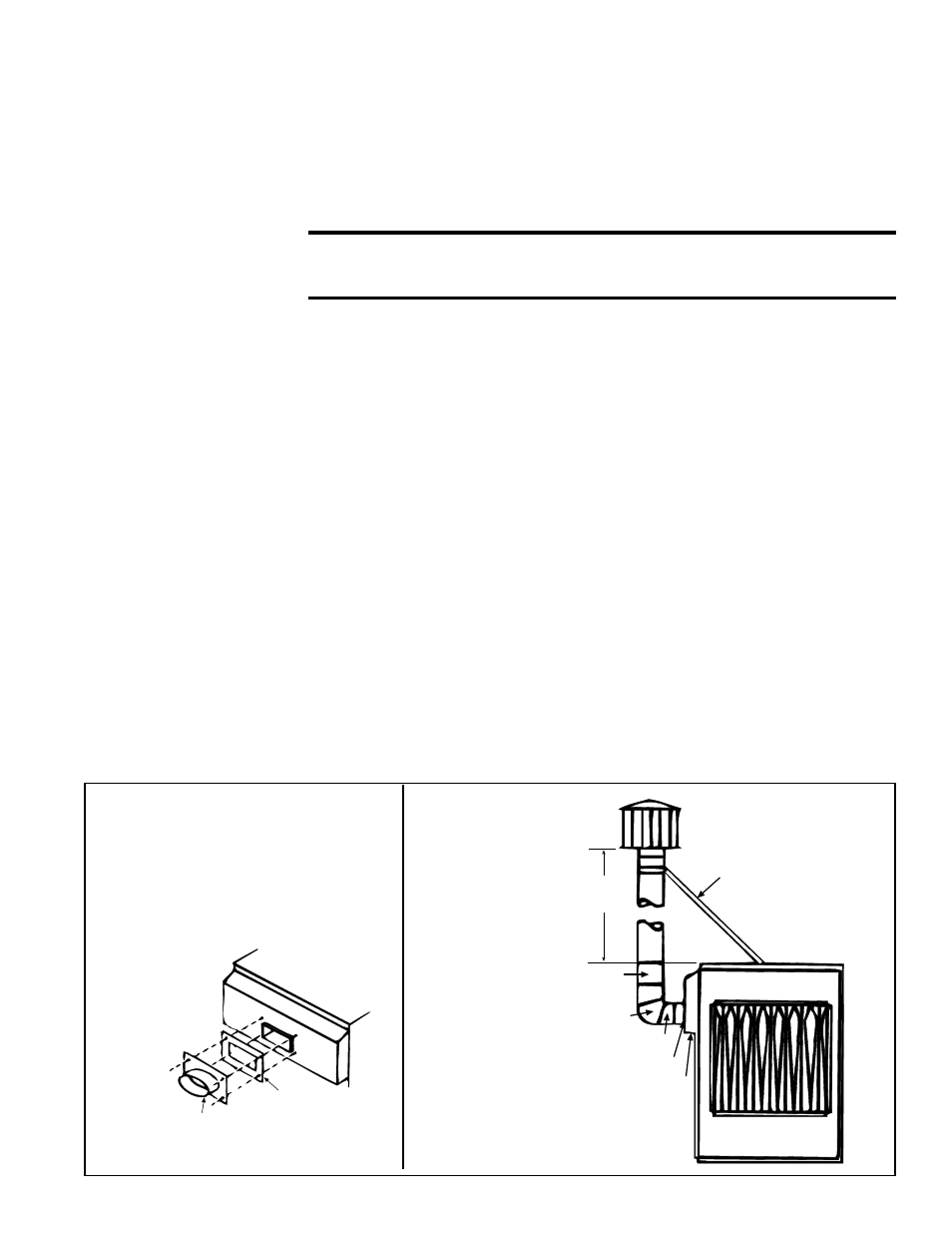

Oval Adapter Assy,

PN/ 103025

Venter Seal Plate,

P/N 43446

FIGURE 5A - Installation of Adapter

for Optional Vertical Flue Discharge

(Option CC3, P/N 45021)

Attach the venter seal plate and oval

adapter assembly with sheetmetal

screws. Use venter seal plate as drill

template.

5 Vent Cap,

P/N 110052

5 dia Flue Pipe

4

(1.2M)

5 dia

90° Elbow

18 (457mm) Straight Pipe

Oval Adapter Assy

Combustion Air Intake

Support angles for flue pipe.

Recommended size is

1/2x1/2, 20 gauge

FIGURE 5B -

Installation of

the Vent Cap

(included in the

option pkg) and

the field-supplied

piping and

supports