0 controls (cont'd), 5 pilot and ignition systems, 4 gas controls (cont'd) – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 22

Form I-RP/HRPD, P/N 132210 R14, Page 22

8.5 Pilot and

Ignition

Systems

8.0 Controls

(cont'd)

8.4 Gas Controls (cont'd)

8.4.5 Optional Electronic Modulation (cont'd)

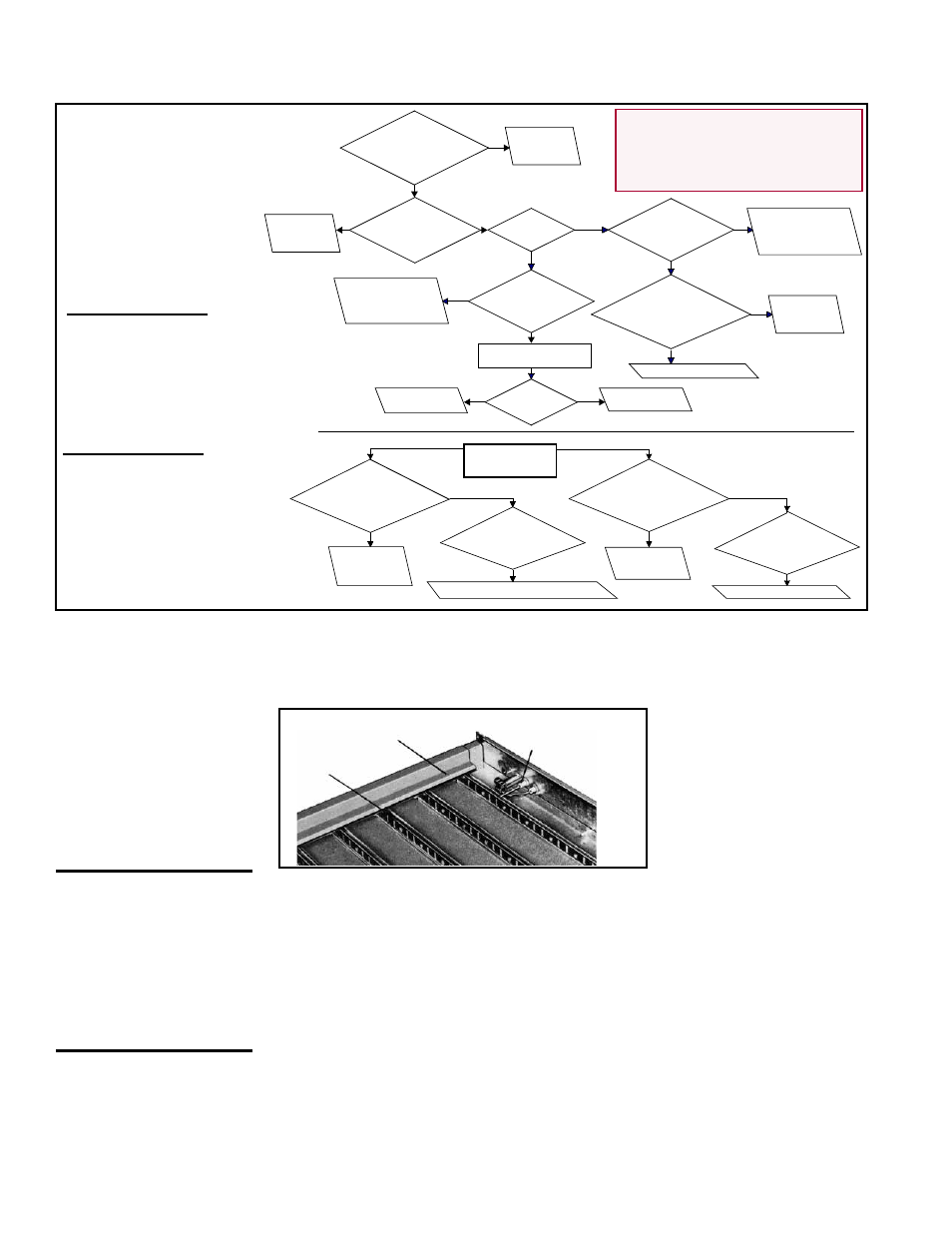

Troubleshooting

Guides for Checking

Bypass Combustion

Air Damper Safety

Circuit with Option

AG39, AG40, AG41,

or AG42

Is there 24 volts

between Terminal 2 on #1

Time Delay Relay and

Terminal 7?

Go to

Troubleshooting

Chart for heater.

Is there 24 volts

between Terminal 84 and

Terminal 7?

Is the

damper open?

Is there voltage

between Terminal 88 and

Terminal 7?

Is there voltage

between Terminal 4 on

ignition permissive relay and

Terminal 7?

Replace #1 time delay relay.

Replace ignition

permissive

relay.

Check combustion

damper lower end switch

adjustment. If necessary,

replace end switch.

Is there voltage

between Terminal 87 and

Terminal 7?

Check combustion

damper lower end switch

adjustment. Replace end

switch if necessary.

Place a jumper across

Terminal 86 and Terminal 7.

Did the

damper close?

Replace motor run

time delay relay.

Replace combustion

damper gear motor.

Replace primary

manifold

pressure switch.

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

YES

NO

General Instructions: For each

step, check to ensure that the

wiring is not defective and that the

wiring connections are secure.

Symptom - Part 1:

Main burners are inoperative.

Assumes that 24 volts is

available between Terminal 2

and Terminal 7.

Symptom - Part 2:

Steady call for heat -

burner cycles.

Assumes constant voltage

between Terminals 11 and

7 and Terminals 2 and 7.

Measure manifold

pressure

during burner cycling.

When the

manifold pressure is

BELOW 1.0" w.c., is there a steady

voltage between Terminal 95

and Terminal 7?

Replace secondary

manifold pressure

switch.

While the

burner is cycling, is

there a steady voltage

between Terminal 84 and

Terminal 2?

Replace the primary manifold pressure switch.

When the

manifold pressure is

ABOVE 1.5" w.c., is there a steady

voltage between Terminal 95

and Terminal 7?

Replace secondary

manifold pressure

switch.

Is there voltage

between Terminal 4 of the

ignition premissive relay and

Terminal 7?

Replace ignition permissive relay.

YES

NO

YES

NO

YES

NO

Flash Carryover

FIGURE 16 - Burner

Rack with Spark Pilot

Main

Burner

Spark Pilot

The horizontal pilot is located in the control end of the burner rack and is accessible

after the control compartment panel has been removed. All pilots are target type with

lint-free feature. Pilot gas pressure should be the same as supply line pressure. (See

Paragraph 6.1.) If required, adjust the pilot flame length to approximately 1-1/4" with

pilot adjustment screw in control valve body.

Intermittent Spark Ignition Safety Pilot Systems - There are two types of intermit-

tent spark pilots -- one type shuts off the pilot gas flow between the cycles and the

other not only shuts off the pilot gas flow between cycles but also has a lockout device

that stops the gas flow to the pilot if the pilot fails to light in 120 seconds. This lockout

feature has a 1-hour retry or requires manual reset by interruption of the thermostat

circuit. Propane units installed in Canada require the spark ignition system with the

lockout device. Refer to the wiring diagram supplied with the heater for pilot system

identification and wiring. Spark pilot without lockout is designated as Option AH2; with

lockout as Option AH3.

CAUTION: Due to

high voltage on

pilot spark wire

and pilot electrode,

do not touch when

energized. See

Hazard Levels,

page 2.

Ignition Controller - As part of the intermittent safety pilot systems, the ignition con-

troller provides the high voltage spark to ignite the pilot gas and also acts as the flame

safety device. After ignition of the pilot gas, the ignition controller electronically senses

the pilot flame. A low voltage DC electrical signal is imposed on the separate metal

probe in the pilot assembly. The metal probe is electrically insulated from ground. The

pilot flame acts as a conduction path to ground completing the DC circuit and proving

pilot flame.

Proper operation of the electronic spark ignition system requires a

minimum flame signal of .2 microamps as measured by a microampmeter. With

pilot flame proven, the ignition controller energizes the main gas valve.