0 uncrating and preparation, 0 furnace location (cont'd), 1 uncrating and inspecting – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 4

Form I-RP/HRPD, P/N 132210 R14, Page 4

3.0 Uncrating and

Preparation

3.1 Uncrating and Inspecting

This furnace was test operated and inspected at the factory prior to crating and was in

operating condition. If the furnace has incurred any damage in shipment, document the

damage with the transporting agency and immediately contact an authorized Reznor

®

distributor. If you are an authorized Distributor, follow the FOB freight policy procedures

as published by Reznor, LLC.

Check the rating plate for the gas specifications and electrical characteristics of the

furnace to be sure that they are compatible with the gas and electric supplies at the

installation site.

3.2.1 Shipped-Separate Components

Read this booklet and become familiar with the installation requirements of your par-

ticular furnace. If you do not have knowledge of local requirements, check with the local

gas company or any other local agencies who might have requirements concerning

this installation. Before beginning, make preparations for necessary supplies, tools,

and manpower.

Check to see if there are any field-installed options that need to be assembled to the

furnace prior to installation.

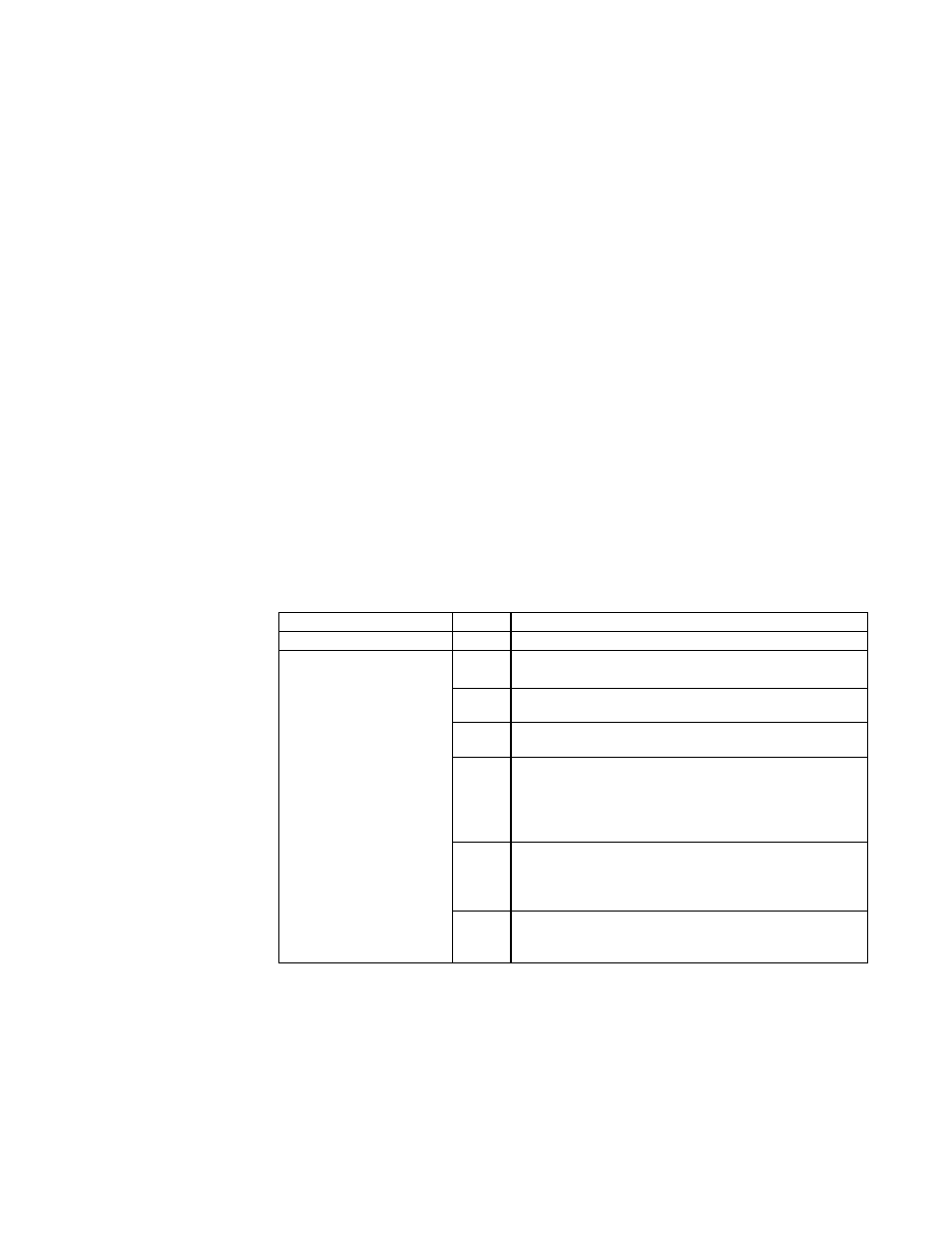

Option Parts - Some gas control options will have parts either shipped loose with the

heater or shipped separately. If your unit is equipped with any of the gas control options

in the table below, be sure these parts are available at the job site.

2.0 Furnace

Location

(cont'd)

2.2 Combustion Air Requirements (cont'd)

3.2 Preparing the

Furnace for

Installation

Other shipped-separate options could include a gas shutoff valve, a vertical vent termi-

nal, a thermostat, an optional control, and/or a disconnect switch.

Check to see if there are any field-installed options that need to be assembled to the

furnace prior to installation.

3.2.2 Instructions for

Reversing Airflow by

Changing Direction

of Heat Exchanger Air

Baffles - Model RP

Model RP duct furnaces are equipped with directional air baffles between the heat

exchanger tubes as shown in

FIGURE 1. Facing the control compartment of the fur-

nace, the standard direction of airflow is from left to right.

If the installation requires direction of airflow from right to left when facing the con-

trol compartment, follow the instructions in

FIGURE 1 to reposition the directional air

baffles at the installation site.

any condensation that is present in the heat exchanger or associated parts. The result

is hydrochloric acid which readily attacks all metals including 300 grade stainless steel.

Care should be taken to separate these vapors from the combustion process. This may

be done by wise location of the furnace with regard to exhausters or prevailing wind

direction. Remember, chlorine is heavier than air. This fact should be kept in mind when

determining installation locations of heating equipment and building exhaust systems.

Application

Option Shipped Separate Components

Heating -- Gas Control AG7

Thermostat,

P/N 48033

Makeup Air -- Gas

Control Options

(NOTE: If an optional

remote console

is ordered, the

control switch and

temperature selector

may be mounted on the

console.)

AG3,

AG4

Control Switch,

P/N 29054

AG8

Control Switch,

P/N 29054; Sensor & Mixing Tube,

P/N 48041

AG9

Control Switch,

P/N 29054; Remote Temperature

Selector,

P/N 48042; Sensor & Mixing Tube, P/N 48041

AG15

Control Switch,

P/N 29054; Remote Temperature

Selector,

P/N 115848; Stage Adder Module, P/N 115849

-

(1) for RP or (3) for HRPD; Discharge Air Sensor

Holder,

P/N 115850; Discharge Air Sensor Holder

Bracket,

P/N 213612

AG17

Control Switch,

P/N 29054; Remote Temperature

Selector,

P/N 115848; Stage Adder Module, P/N 115849;

Discharge Air Sensor Holder,

P/N 115850; Discharge Air

Sensor Holder Bracket,

P/N 213612

AG39,

AG41

Remote Temperature Selector,

P/N 174849;

Temperature Sensor,

P/N 133228; Mixing Tube,

P/N 90323