0 mechanical (cont'd) – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 12

Form I-RP/HRPD, P/N 132210 R14, Page 12

6.3 Duct Furnace Air

Flow (cont'd)

6.3.4 Duct

Connections (cont'd)

6.0 Mechanical

(cont'd)

Heater

Duct

Access

Panel in Duct

6

(152mm)

10 (254mm)

1

2

3

4

U Channel

(See FIGURE 11.)

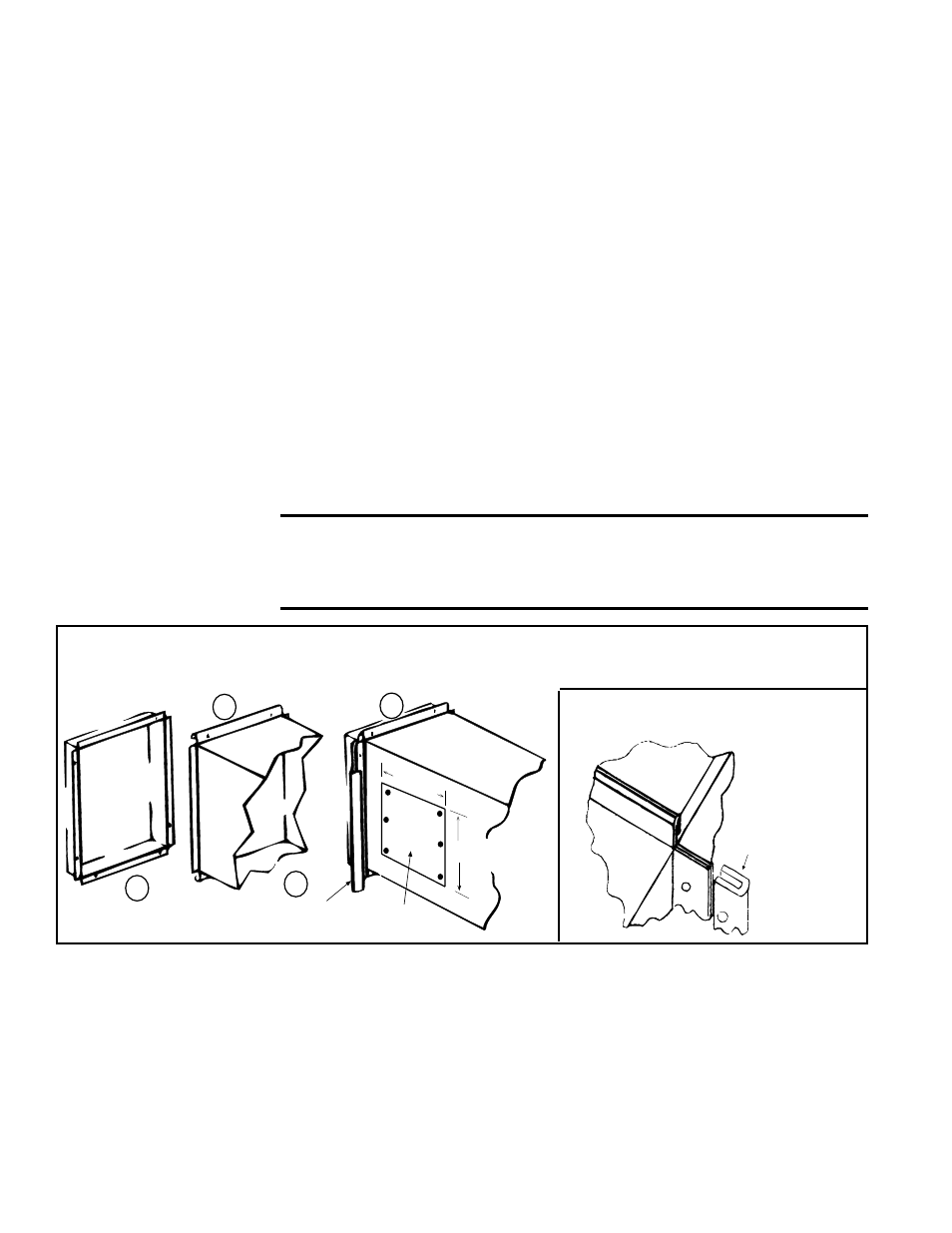

FIGURE 9A -

Connecting Supply Air

Duct to the Furnace

Furnace

Duct

U Channel

of Light Gauge

Metal

(1) Flanges on the furnace (heat exchanger) turn out as shown. (2) Shape duct connection as shown -- "U" on top

and bottom; "L" on sides. (3) Slide "U" channels over furnace top and bottom flanges making connection. (4) Form

"U" channels to seal sides.

Drill and lock with sheetmetal screws.

FIGURE 9B - "U" Channel Duct

Connection

•

Through Unheated Space - Insulate all exposed warm air ducts passing through

an unheated space with at least 1/2" (1" is recommended) of insulation.

•

Duct Supports - Suspend all ducts securely from building members. Do not sup-

port ducts from unit duct connections.

•

Duct Sizing - Proper sizing of the supply air ductwork is necessary to ensure a

satisfactory heating installation. The recognized authority for such information is

the Air Conditioning Contractors Association, 2800 Shirlington Road, Suite 300,

Arlington, VA 22206 (www.acca.org). A manual covering duct sizing in detail may

be purchased directly from them.

•

Removable Panels - The ducts should have removable access panels on both

upstream and downstream sides of the furnace. These openings must be acces-

sible when the furnace is in service and should be a minimum of 6" x 10" in size

so smoke or reflected light may be observed inside the casing to indicate the pres-

ence of leaks in the heat exchanger. The covers for the openings must be attached

in such a manner as to prevent leakage. See

FIGURE 9A.

•

Horizontal Discharge Duct Length - A minimum horizontal duct run of 24"

(610mm) is

recommended before turns or branches are made in the duct system

to reduce losses at the furnace outlet.

•

Supply Air Duct/Furnace Horizontal Connection - The seal between the fur-

nace and the duct must be mechanical. Duct connection should be made with "U"

type flanges on the top and bottom of the connecting duct. Slide the duct over the

flanges of the heater giving an airtight fit. Provide "U" type channels for the other

side flanges to ensure tight joints. Use sheetmetal screws to fasten ducts and "U"

channels to the furnace flange. See

FIGURES 9A and 9B.

CAUTION: Joints where supply air ducts attach to the furnace

must be sealed securely to prevent air leakage. Leakage can

cause poor combustion, pilot problems, shorten heat exchanger

life, and cause poor performance.

Requirements and Suggestions (cont'd)

6.3.5 Discharge Air

Sensor for Makeup

Air Application

Makeup air Options AG3 and AG4 have a unit mounted ductstat with a capillary sensor

that is factory-installed in the unit discharge (See Paragraph 8.4.3).

Makeup air Options AG15, AG17, AG8, AG9, AG39, AG40, AG41, and AG42 require

field installation of the sensor in the discharge ductwork.

Option AG15 and AG17 use the box and sensor holder in

FIGURE 10A.

Options AG8, AG9, AG39, and AG41 include a sensor and mixing tube like the one

illustrated in

FIGURE 10B. Options AG40 and AG42 require a field-supplied sensor.

Follow the instructions below to install the sensor in the ductwork.

For control information, see Paragraph 8.4.