0 mechanical (cont'd), 3 duct furnace airflow, 1 pressure drop and temperature rise by size – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 10: 2 duct furnace blower connections

Form I-RP/HRPD, P/N 132210 R14, Page 10

6.0 Mechanical

(cont'd)

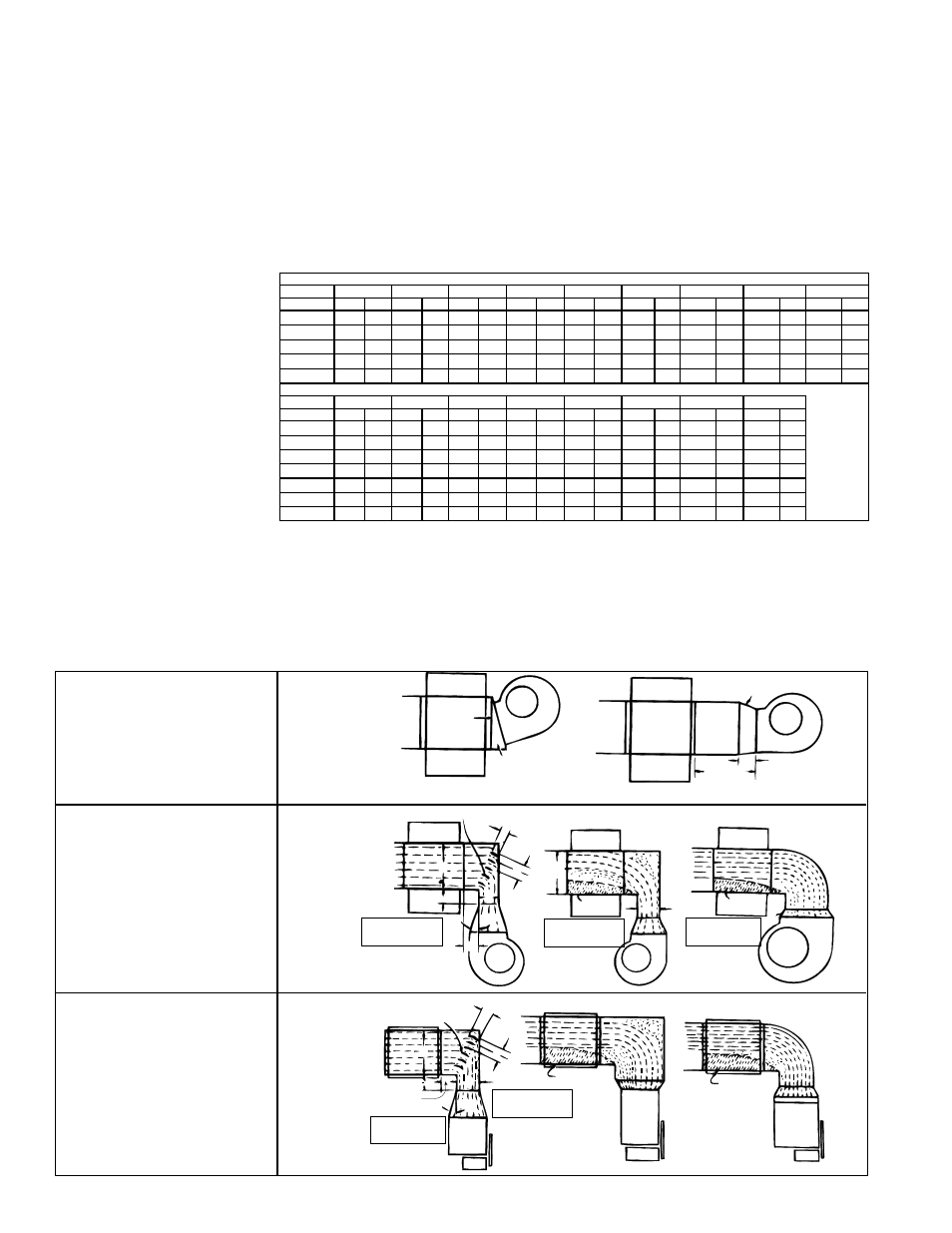

6.3.1 Pressure Drop and Temperature Rise by Size

The duct furnace must be installed on the positive pressure side of the field supplied

blower. The air throughput must be within the CFM range stated on the heater rat-

ing plate. The air distribution must be even over the entire heat exchanger. Turning

vanes should be used in elbows or turns in the air inlet to ensure proper air distribu-

tion (See Paragraph 6.3.2). If it is determined that the blower CFM is greater than

allowed or desirable, see Paragraph 6.3.3 for instructions on determining the correct

size of bypass duct required. To determine temperature rise, the inlet and outlet air

temperatures should be measured at points not affected by heat radiating from the

heat exchanger. The charts below show the approved temperature rise range with the

required CFM and the internal pressure drop for each size of unit.

6.3 Duct Furnace

Airflow

Model RP (80% thermal efficient)

Size

125

150

175

200

225

250

300

350

400

Temp Rise CFM P.D. CFM P.D. CFM P.D. CFM P.D. CFM P.D. CFM P.D. CFM P.D. CFM P.D. CFM P.D.

50°F

1840 0.50 2210 0.38 2580 0.52 2945 0.42 3315 0.53 3685 0.40 4420 0.58 5160 0.65 5895 0.7

60°F

1535 0.33 1840 0.26 2150 0.35 2455 0.28 2765 0.36 3070 0.28 3685 0.39 4300 0.44 4915 0.5

70°F

1315 0.25 1580 0.19 1840 0.26 2105 0.22 2370 0.27 2630 0.23 3160 0.29 3685 0.31 4210 0.3

80°F

1150 0.21 1380 0.15 1610 0.19 1840 0.17 2070 0.22 2300 0.22 2765 0.25 3225 0.25 3685 0.3

90°F

1020 0.18 1225 0.12 1430 0.16 1635 0.14 1840 0.17 2045 0.21 2455 0.22 2865 0.23 3275 0.2

Model HRPD

SIZE

250

300

350

400

500

600

700

800

Temp Rise CFM PD CFM PD CFM PD CFM PD CFM PD CFM PD CFM PD CFM PD

40°F

4630 1.97 5556 1.45 6481 2.02 7407 1.70 9259 1.53 11111 2.14 12963 2.09 14815 2.09

50°F

3704 1.26 4444 0.92 5185 1.29 5926 1.09 7407 0.98 8889 1.37 10370 1.34 11852 1.34

60°F

3086 0.88 3704 0.64 4321 0.90 4938 0.76 6173 0.68 7407 0.95 8642 0.93 9877 0.93

70°F

2646 0.64 3175 0.47 3704 0.66 4233 0.56 5291 0.50 6349 0.70 7407 0.68 8466 0.68

80°F

2315 0.49 2778 0.36 3241 0.51 3704 0.43 4630 0.38 5556 0.54 6481 0.52 7407 0.52

90°F

2058 0.39 2469 0.29 2881 0.40 3292 0.34 4115 0.30 4938 0.42 5761 0.41 6584 0.41

100°F

1852 0.32 2222 0.23 2593 0.32 2963 0.27 3704 0.24 4444 0.34 5185 0.33 5926 0.33

6.3.2 Duct Furnace

Blower Connections

Proper arrangement of blower and duct furnace with respect to angle of approach of

the duct connection and the arrangement of the discharge opening of the blower is

required. Blowers should be bottom horizontal discharge when coupled to the duct

furnace. When a top horizontal discharge blower is connected to the duct furnace, be

sure that sufficient length of duct is provided to permit even flow of air at the end of the

duct. Or, baffles may be inserted between the blower and the heater to assure an even

flow of air across the heat exchanger.

Direct

Coupling

Slanted Transition

Suggested blower connections for straight through airflow.

Use either method for good air coverage and efficient operation.

15°

6 (152mm)

Remote

24

(610mm)

minimum

Turning Vanes

3(76mm)

3(76mm)

3(76mm)

6 (152mm)

6

(152mm)

X

15°

Y

No air

X

No air

Z

NOTE: X should

never be less than

1/2 Y

NOTE: X should

never be less

than 1/2 Y

NOTE: Angle Z

should never be

more than 15°

Turning Vanes

3(76mm)

3(76mm)

3(76mm)

6 (152mm)

6 (152mm)

Z

NOTE: Angle Z

should never be

more than 15°

X

15°

No air

GOOD

GOOD

POOR

POOR

POOR

No air

POOR

Y

Y

NOTE: X should

never be less

than 1/2 Y

FIGURE 6A -

Straight

Through Air

FIGURE 6B -

With Elbows

Up or Down

FIGURE 6C -

With Elbows

Right or Left