0 controls (cont'd), 4 gas controls (cont'd) – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 20

Form I-RP/HRPD, P/N 132210 R14, Page 20

8.0 Controls

(cont'd)

8.4 Gas Controls

(cont'd)

8.4.4 Optional Electronic Modulation (cont'd)

Electronic Modulation

between 20-28% and

100% Firing Rate -

Options AG39 & AG40

(natural gas only Model

RP only; not available

on Size 350) and

Options AG41 & AG42

(natural gas only Model

HRPD; not available on

Size 700)

Depending on the size, furnaces equipped with electronic modulation Option AG39,

AG40, AG41, or AG42, have a 20-28% turndown ratio. The furnace will ignite at any

input rate in the available range and will maintain average thermal efficiencies equal to

or greater than the thermal efficiency at full fire.

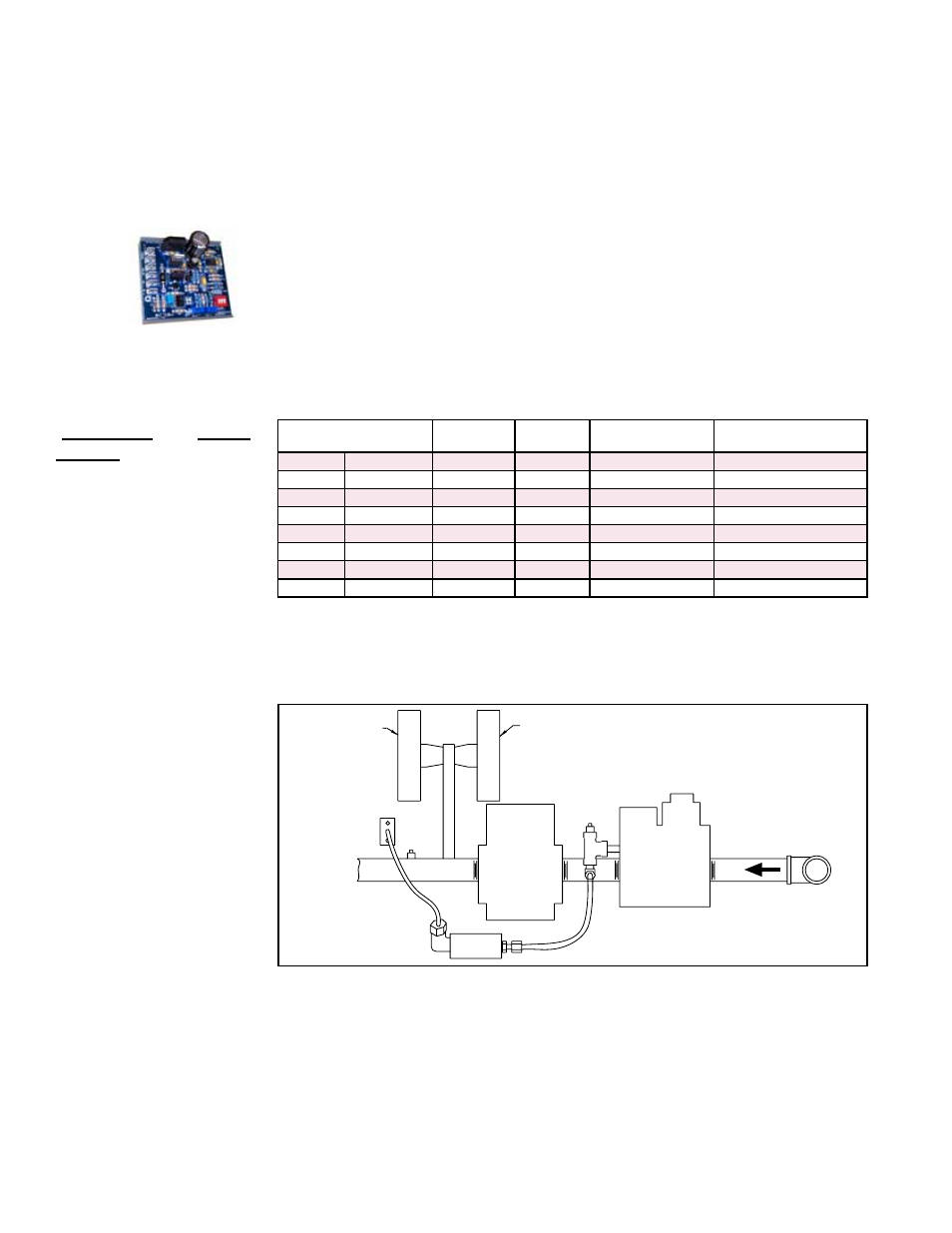

FIGURE 14B - Maxitrol

Signal Conditioner in

Options AG21, AG40, &

AG42

gu

Carryover

Regulator

Modulating

Valve

Single-

Stage Gas

Valve

P rimary Gas

Flow Pressure

Switch

White Label

1.1 w.c.

Gas Flow

Pressure Switch

White Label

1.1 w.c.

FIGURE 15 - Option

Manifold Arrangement

Model / Size

Maximum

Turndown

MBH Inlet

Range

Inlet Pressure to

Modulating Valve

Gas Supply Pressure

Required

RP 125

HRPD 250

20%

25-125

3.9" w.c.

5" w.c.

RP 150

HRPD 300

27%

40.3-150

3.7" w.c.

5" w.c.

RP 175

HRPD 350

23%

40.3-175 3.7" w.c.

5" w.c.

RP 200

HRPD 400

26%

51.8-200 3.9" w.c.

5" w.c.

RP 225

23%

51.8-225 3.9" w.c.

5" w.c.

RP 250

HRPD 500

28%

69-250

4.0" w.c.

5" w.c.

RP 300

HRPD 600

23%

69-300

4.0" w.c.

5" w.c.

RP 400

HRPD 800

25%

100-400

4.4" w.c.

6" w.c

The gas train includes a single-stage gas valve, a modulating valve, and two gas pres-

sure switches. The burner rack is equipped with one flash carryover and a regulated

gas lighter tube system. The carryover lighter tube receives its gas supply through the

regulator, simultaneously with the gas to the burner. Control of the system is through a

Maxitrol amplifier with a corresponding remote temperature dial

Description of

Operation - Options

AG39, AG40, AG41,

AG42

The gas supply (see pressure requirements in the table above) connects to the single-

stage gas valve. To compensate for additional pressure loss through the modulating

valve, the single-stage gas valve has a custom outlet pressure setting higher than

when it is used on a standard gas manifold. The pilot tubing connects to the pilot port

on the single-stage gas valve. When the valve receives a call for heat from the ampli-

fier and pilot is established, gas flow from the single-stage valve goes to both the mod-

ulating valve and the regulated lighter tube system. When the signal from the amplifier

to the modulating valve requires less-than-high fire operation, the modulating valve

functions to lessen the gas flow to the burner to reduce the input rate to that required to

maintain the desired temperature. When the input rate is reduced enough to decrease

air applications controlled by a field-installed duct sensor (See Paragraph 6.3.5.) and

temperature selector (55-90°F) are identified as either Option AG8 or Option AG9.

The temperature selector setting for Option AG8 is on the amplifier; Option AG9 has a

remote temperature selector. Both systems are available with an override thermostat.

Computer Controlled Electronic Modulation between 50% and 100%

Firing Rate (Option AG21)

With this option the furnace is equipped with a Maxitrol signal conditioner which oper-

ates much the same way as the amplifier above to control the regulator valve. The con-

ditioner accepts an input signal of either 4-20 milliamps or 0-10 volts from a customer-

supplied control device such as a computer. With the dip switches on the conditioner in

the "on" positions, the conditioner accepts a 4-20 milliamp signal. In the "off" positions,

the conditioner accepts a 0-10V signal. The conditioner converts the signal to the 0 to

20 volt DC current required to control the modulating valve.