6 burners and carryover system, 7 burner air adjustment – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 23

Form I-RP/HRPD, P/N 132210 R14, Page 23

Service NOTE: If replacing an earlier model

of ignition controller, order replacement kit

P/N

257472 for a unit with recycling gas control

Option AH2 or

P/N 257473 for Option AH3 gas

control with lockout. (Option codes are listed on

the unit wiring diagram.)

Recycling Ignition

Controller, UTEC

1003-638A, P/N

257009, for Option

AH2 Gas Control

Ignition Controller

with Lockout, UTEC

1003-514, P/N 257010,

for Option AH3 Gas

Control

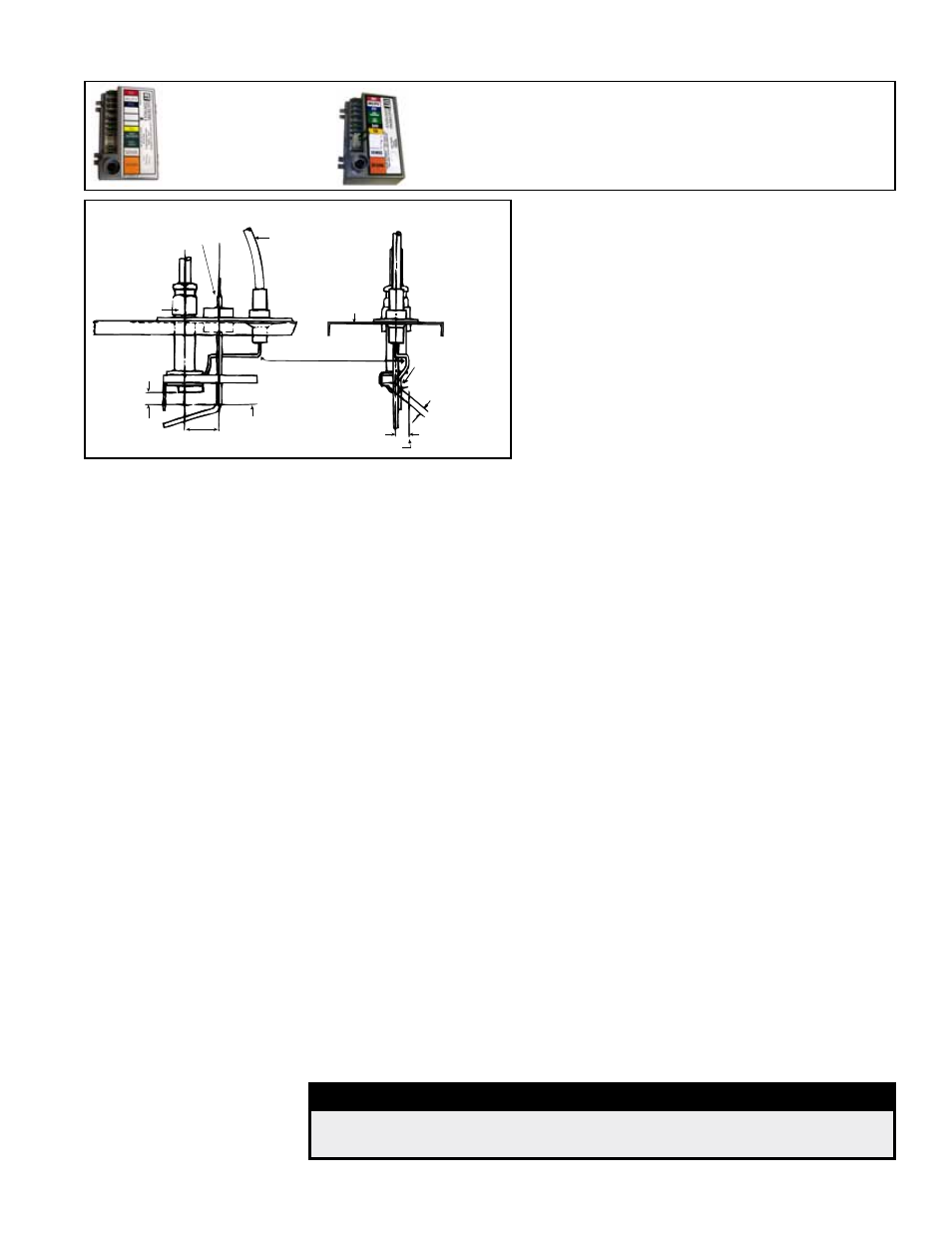

FIGURE 17 - Ignition Controller

Flame Sensing Probe

Pilot

Orifice

Centerline of

first burner

High Tension

Lead

Burner

Rack

Front

Spark Electrode

Spark Gap

7/64 (2.78mm)

TOP VIEW OF BURNER

TOP

VIEW

SIDE

VIEW OF

PILOT

1/4± 1/32

(6.38mm±.79)

23/32

(18.25mm)

7/16± 1/16

(11mm±1.6)

FIGURE 18 - Maintain spark gap of 7/64"

If no spark occurs, check the following:

a) Voltage between Terminals TH and 7 on the ignition

controller should be at least 20 volts and no higher

than 32 volts. Refer to Troubleshooting (Paragraph

10.3) if no voltage is observed.

b) Short to ground in the high tension lead and/or

ceramic insulator.

c) Pilot spark gap should be approximately 7/64".

NOTE: When checking for spark with the pilot burner

assembly removed from the burner rack, the pilot

assembly must be grounded to the heater for proper

spark.

If the above conditions are normal and no spark occurs,

replace the ignition controller.

If the main gas valve fails to open with a normal full size pilot flame established, check

for the following:

a) Voltage between black and brown leads on the main gas valve is 20 to 32 VAC

and there is no main gas flow with the built-in manual valve in FULL OPEN

position -- the main valve is defective.

b) No voltage between black and brown leads on the main gas valve -- check for

disconnected or shorted flame sensor lead or flame sensor probe.

When the above conditions are normal and the main gas flow is still off, the ignition

controller is probably defective.

8.6 Burners and

Carryover

System

These duct furnaces have individually formed steel burners with accurately die-formed

ports to give controlled flame stability without lifting or flashback with either natural or

propane gas. The burners are lightweight and factory mounted in an assembly which

permits them to be removed as a unit for inspection or service.

Natural gas burner racks (except when equipped with electronic modulation Option

AG39, AG40, AG41, or AG42; see Paragraph 8.4) are equipped with two flash car-

ryovers. Propane gas burners are equipped with one flash carryover and a regulated

gas lighter tube system.

During regular service, check the main burner ports, the carryover assemblies, and the

orifices for cleanliness.

8.7 Burner Air

Adjustment

Burner air shutters are not normally required on natural gas furnaces. Air shutters are

required on propane gas units and may require adjustment.

Before making any adjustments to the air shutters, allow the heater to operate for

about fifteen minutes with the air shutters open. The slotted screw on the end mani-

fold bracket moves the air shutters and adjusts all burners simultaneously. Turning

the screw clockwise opens the shutters; counterclockwise closes the shutters. After

the furnace has been in operation for 15 minutes, close the air shutters observing

the flame for yellow-tipping. Open the shutters until the yellow disappears. A limited

amount of yellow-tipping is permissible for liquefied petroleum gases. Natural gas

should not display any yellow-tipping.

When making the adjustment, close the air shutters no more than is necessary to elimi-

nate the problem condition.

DANGER

Failure to install and/or adjust air shutters according to directions

could cause property damage, personal injury, and/or death.