0 controls (cont'd), 4 gas controls (cont'd) – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 18

Form I-RP/HRPD, P/N 132210 R14, Page 18

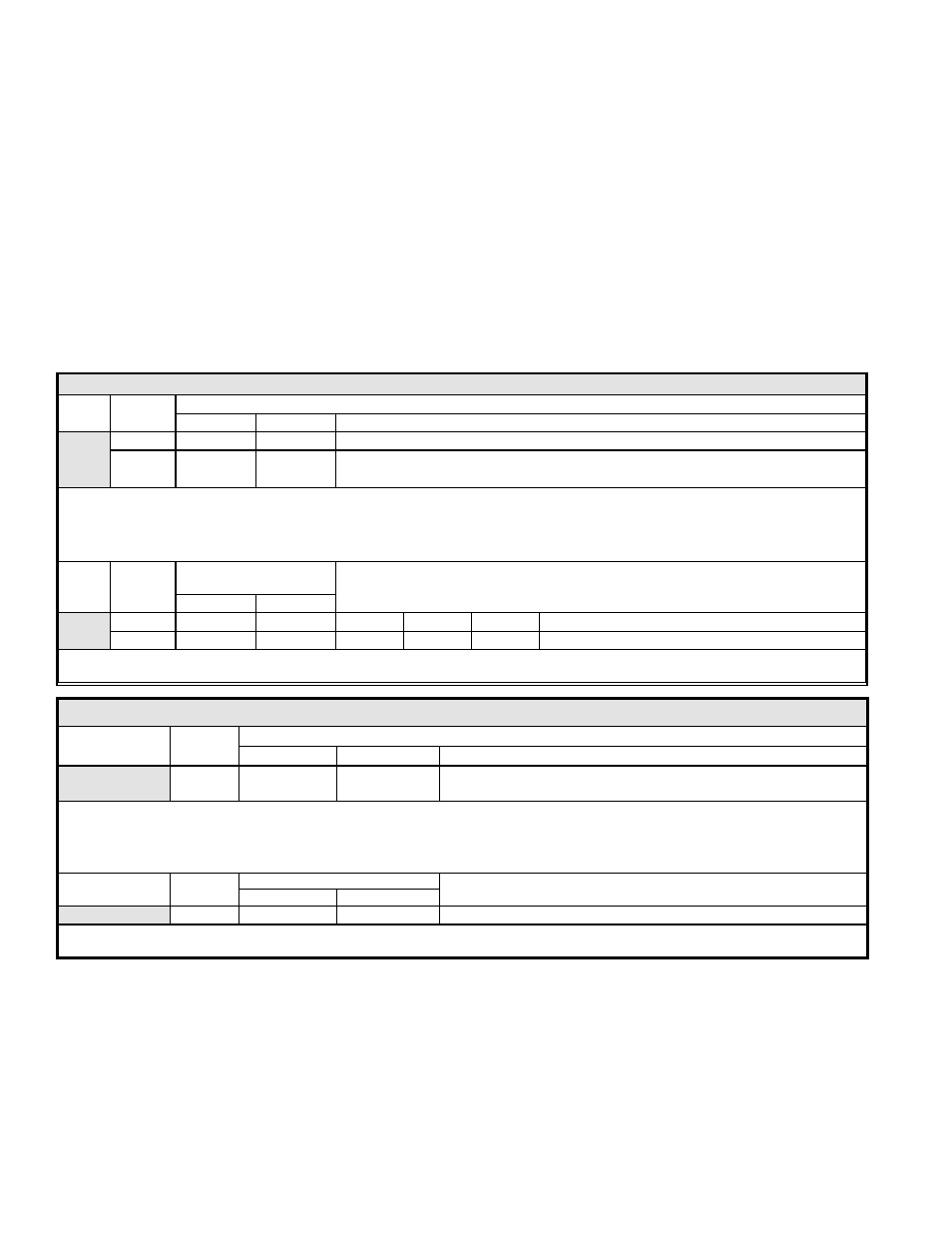

TABLE A - Recommended Settings for Staging Application - Options AG3 and AG15

Option

No. of

Furnaces

Ductstat Settings - Set

the Ductstat (See FIGURE 12A)

1st

2nd

Sequence of Staging with these settings

AG3

1

70°F

--

66°F High Stage ► 70°F Low Stage ► 74°F Shutdown

2

70°F

64°F

60°F High Stage Both Furnaces ► 64°F Low Stage 2nd Furnace ► 68°F Shutdown

2nd furnace ► 70°F Low Stage 1st furnace ► 74°F Shutdown 1st furnace

Option AG15 - Adjust the setpoint and the differential of the temperature selector (Johnson #A350). Adjust the offset

potentiometer on each of the stage adder modules (Johnson #S350). The settings listed below will provide the same sequence

of staging as shown above for Option AG3. Follow the manufacturer's instructions provided.

IMPORTANT: Set the temperature

selector and each stage adder module to "HEAT". Follow the wiring diagram to obtain proper sequencing.

Option

No. of

Furnaces

Temperature Selector

(A350)

Stage Adder (S350) Offset Settings (Refer to

FIGURE 13)

Setpoint

Differential

AG15

1

74°F

8°F

4°F

--

--

2

74°F

14°F

10°F

6°F

4°F

Operation: The differential setting and offset degrees allow the controls to adapt to any adjustment in temperature selection (50-

130°F).

ductstat setting, high fire is energized. Model HRPD includes two furnace sections and

each section is equipped with a two-stage gas valve. Set the ductstat (

FIGURE 12A or

13) as indicated in TABLE A, below.

The second method of multiple-stage makeup air operation is applicable only to

Model HRPD and is identified as Option AG4 or AG17. Each furnace in the package

is equipped with a single-stage gas valve. The single-stage gas valves are staged by

a two-stage ductstat. The furnaces are staged in sequence. This concept will achieve

two-stage control. Set the ductstat as indicated in

TABLE B.

The two types of ductstat control mechanisms used in these multiple-stage systems

are

either --

(1) the ductstat with temperature selector and attached capillary sensor is factory

installed (Option AG3 and AG4; see

FIGURE12A, or

(2) a sensing probe must be field installed in the heater discharge (See Paragraph

6.3.5). The sensing probe is wired to a remote, field-installed, electronic

temperature selector (

FIGURE 13).

8.0 Controls

(cont'd)

8.4 Gas Controls

(cont'd)

8.4.3 Optional Two-Stage Operation - Makeup Air (cont'd)

TABLE B - Recommended Settings for Staging Application - Options AG4 and AG17

Option

No. of

Furnaces

Ductstat Settings - Set

the Ductstat (See FIGURE 12A) i

1st

2nd

Sequence of Staging with this setting

AG4

2

70°F

--

66°F Full Rate Both Furnaces ► 70°F Shutdown 1st Furnace ►

74°F Shutdown 2nd furnace

Options AG17 - Adjust the setpoint and the differential of the temperature selector (Johnson #A350). Adjust the offset

potentiometer on each of the stage adder modules (Johnson #S350). The settings listed below will provide the same sequence

of staging as shown above for Option AG4. Follow the manufacturer's instructions provided.

IMPORTANT: Set the temperature

selector and each stage adder module to "HEAT". Follow the wiring diagram to obtain proper sequencing.

Option

No. of

Furnaces

Temperature Selector (A350)

Stage Adder (S350) Offset Settings

(Refer to illustration in

FIGURE 13)

Setpoint

Differential

AG17

2

74°F

8°F

4°F

Operation: The differential setting and offset degrees allow the controls to adapt to any adjustment in temperature selection (50-

130°F).

Optional Ductstat with Capillary Tubing (Options AG3 and AG4) - These makeup

air control options use a ductstat (See

FIGURE 12A) with an adjustable range from

0° to 100°F with a fixed differential of 3°. Due to different CFM settings and outside air

temperatures, the average downstream outlet temperature may not match the ductstat

setting exactly. After the installation is complete, re-adjust the setpoint of the duct-

stat to achieve the desired average discharge air temperature. In general, makeup air

applications are usually adjusted to discharge an outlet air temperature between 65°F

and 75°F.

Optional Ductstat with Electronic Remote Setpoint Module (Options AG15 and

AG17 ) - These two-stage makeup air options that are controlled from a sensing probe

with a remote electronic temperature selector that has a temperature operating range