0 mechanical, 1 gas piping and pressures – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 7

Form I-RP/HRPD, P/N 132210 R14, Page 7

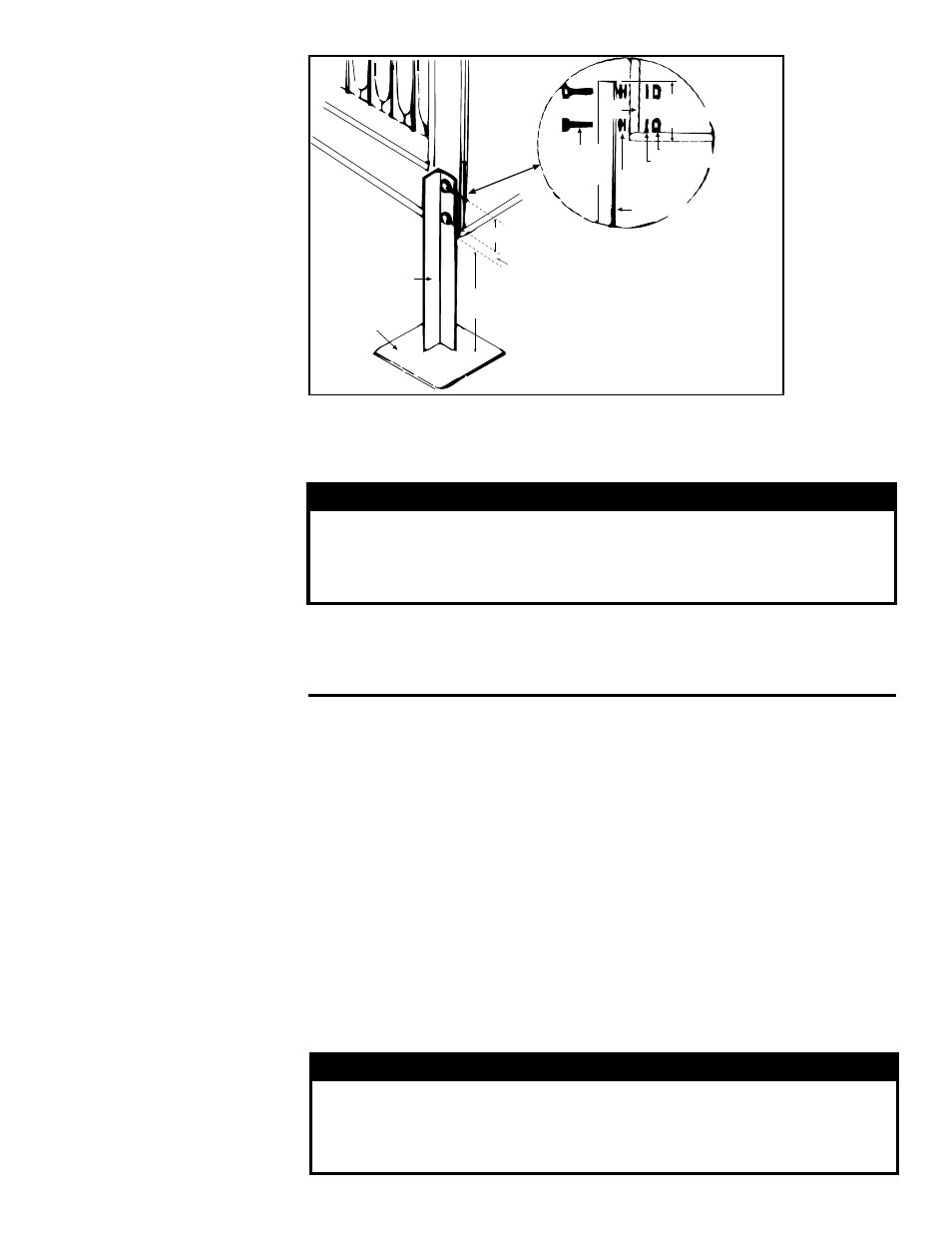

FIGURE 3 - Field-

Fabricated Supports

2 x 2 x 1/4

Angle Iron Leg

6 x 6 x 1/4

Metal Plate

Cabinet Leg

A

4 (102mm)

2-1/4

(57mm)

Cabinet Leg

1/4 Nuts

Lockwashers

Spacers

1/4 x 1-1/2

Hex Head

Bolts

Angle Iron Leg

Drill 9/32 clearance

holes in angle iron

leg and cabinet leg.

A = 3 (76mm) minimum height for

clearance to combustibles. The recommended

height is 8 (203mm) for plumbing and service.

7

(178mm)

NOTE: Drawing is not

proportional; comply with

dimensions as written.

All piping must be in accordance with requirements outlined in the National Fuel Gas

Code NFPA54/ANSI Z223.1 (latest edition) or CSA-B149.1 (latest edition) Natural Gas

and Propane Installation Code. Gas supply piping installation should conform with

good practice and with local codes.

Duct furnaces for natural gas are orificed for operation with gas having a heating value

of 1000 (+ or - 50) BTU per cubic ft. If the gas at the installation does not meet this

specification, consult the factory for proper orificing.

Pipe joint compounds (pipe dope) shall be resistant to the action of liquefied

petroleum gas or any other chemical constituents of the gas being supplied.

Install a ground joint union and manual shutoff valve upstream of the unit control sys-

tem, as shown in

FIGURE 4A. The 1/8" plugged tapping in the shutoff valve provides

connection for supply line pressure test gauge. The National Fuel Gas Code requires

the installation of a trap with a minimum 3" drip leg. Local codes may require a mini-

mum drip leg longer than 3" (typically 6").

After all connections are made, disconnect the pilot supply at the control valve and

bleed the system of air. Reconnect the pilot line and leak-test all connections by brush-

ing on a soap solution.

WARNING

All components of a gas supply system must be leak tested prior

to placing equipment in service. NEVER TEST FOR LEAKS WITH

AN OPEN FLAME. Failure to comply could result in personal

injury, property damage or death.

6.0 Mechanical

WARNING

This appliance is equipped for a maximum gas supply pressure

of 1/2 psi, 3.4 kPa, or 14 inches water column. Supply pressure

higher than 1/2 psi requires installation of an additional service

regulator external to the unit.

PRESSURE TESTING SUPPLY PIPING

Test Pressures Above 1/2 PSI: Disconnect the heater and manual valve from the

gas supply line which is to be tested. Cap or plug the supply line.

Test Pressures Below 1/2 PSI: Before testing, close the manual valve on the heater.

6.1 Gas Piping and Pressures