0 electrical supply and connections, 1 general, 2 supply voltage and wiring – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 13

Form I-RP/HRPD, P/N 132210 R14, Page 13

7.0 Electrical

Supply and

Connections

7.1 General

WARNING

If you turn off the power supply, turn off the gas. See Hazard

Levels, page 2.

All electrical wiring and connections, including electrical grounding MUST be made in

accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or, in

Canada, the Canadian Electrical Code, Part I-C.S.A. Standard C22.1. In addition, the

installer should be aware of and in compliance with any local ordinances or gas com-

pany requirements that might apply.

Instructions for

Installing Discharge Air

Sensor in the Ductwork

1. Depending on the option, the sensor will be as shown in FIGURE 10A, in FIGURE

10B, or field-supplied for Option AG40 or AG42. See Paragraph 3.2 for a list of

shipped-separate components by option code.

2. Determine a location in the ductwork to install the sensor.

Select a location a sufficient distance from the outlet to provide a good mixture of

discharge air temperature. According to the latest edition of AMCA Standard 201,

in straight ducts, the air is typically well mixed a minimum of five equivalent duct

diameters from the discharge of the unit with equivalent duct diameter defined

s equal to the square root of 4AB/3.14. "A" and "B" are the duct cross-sectional

dimensions.

Example:

Supply ductwork cross-sectional dimension is

24" x 12" (610mm x 305mm).

5 x

4 x 12 x 24

3.14

= 96"

5 x

4 x 305 x 610

3.14

= 2435mm

Solution: Locate the sensor a minimum of 96" (2435mm)

from the outlet of the unit.

NOTE: If the length of the discharge duct is less than 8 ft (2.4M), a mixing vane is

recommended for mixing the discharge air.

Do not mount the sensor in the ductwork after a split in the supply as that will

cause loss of control in the duct that does not house the sensor.

3. The position of the sensor holder or mixing tube is important. The holder in

FIGURE 10A will extend 9-3/16” (233mm) into the ductwork. The mixing tube in

FIGURE 10B is 12" (305mm) long.

In horizontal ductwork, locate the sensor assembly in the top, middle of the duct

with the sensor probe extending vertically down into the center of the airstream.

In vertical ductwork, locate the sensor assembly in the middle of the side of the

duct that corresponds with the top middle of the discharge outlet.

Turn the holder so that the element will be shielded from direct airflow and will

sense the air temperature as it flows through the holes in the holder.

At the selected location in the ductwork, mark the diamond-shaped hole

[approximately 1” x 1” (25mm x 25mm)] required for the sensor holder or the round

hole needed for the mixing tube. Cut the hole no larger than required.

4.

Options AG15 and AG17- Push the element into the clip in the holder. Determine

where the sensor wire should enter the box and remove the knockout. Slide

the holder into the ductwork. Using four field-supplied No. 6 sheetmetal screws,

attach the box portion of the holder to the ductwork. Attach a field-supplied cable

connector to the box, connect the sensor wire, and attach the box cover.

Options AG8, AG9, AG39, and AG41 - Slide the mixing tube into the ductwork

and attach the sensor. Connect the wires as shown on the wiring diagram.

Options AG40 and AG42 - Follow the instructions provided with the field-supplied

sensor. Refer to the wiring diagram with the unit and the field-supplied sensor to

connect the wires.

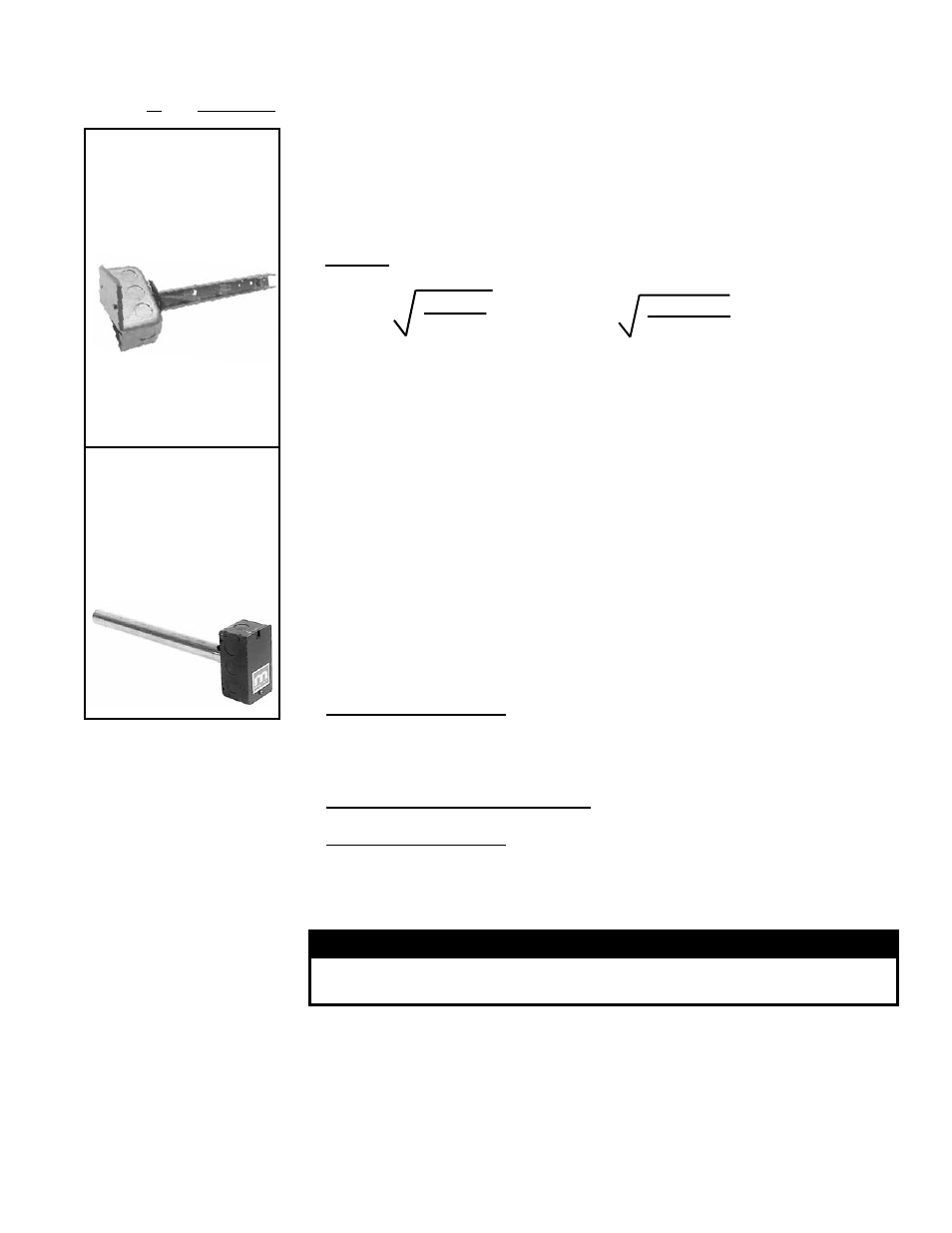

FIGURE 10A -

Discharge Air Sensor

Holder, P/N 115850,

used in Makeup Air

Option AG15 & AG17

Secure sensor in clip.

Position holder so that it

shields sensor from direct

airflow.

FIGURE 10B - A

Discharge Air Sensor

and Mixing Tube are

used in Electronic

Modulation Options

AG8, AG9, AG39, &

AG41

7.2 Supply Voltage

and Wiring

Check the rating plate on the heater for the supply voltage and current requirements.

A separate line voltage supply with fused disconnect switch should be run directly from

the main electrical panel to the furnace, making connection to leads in the junction box.