Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 11

Form I-RP/HRPD, P/N 132210 R14, Page 11

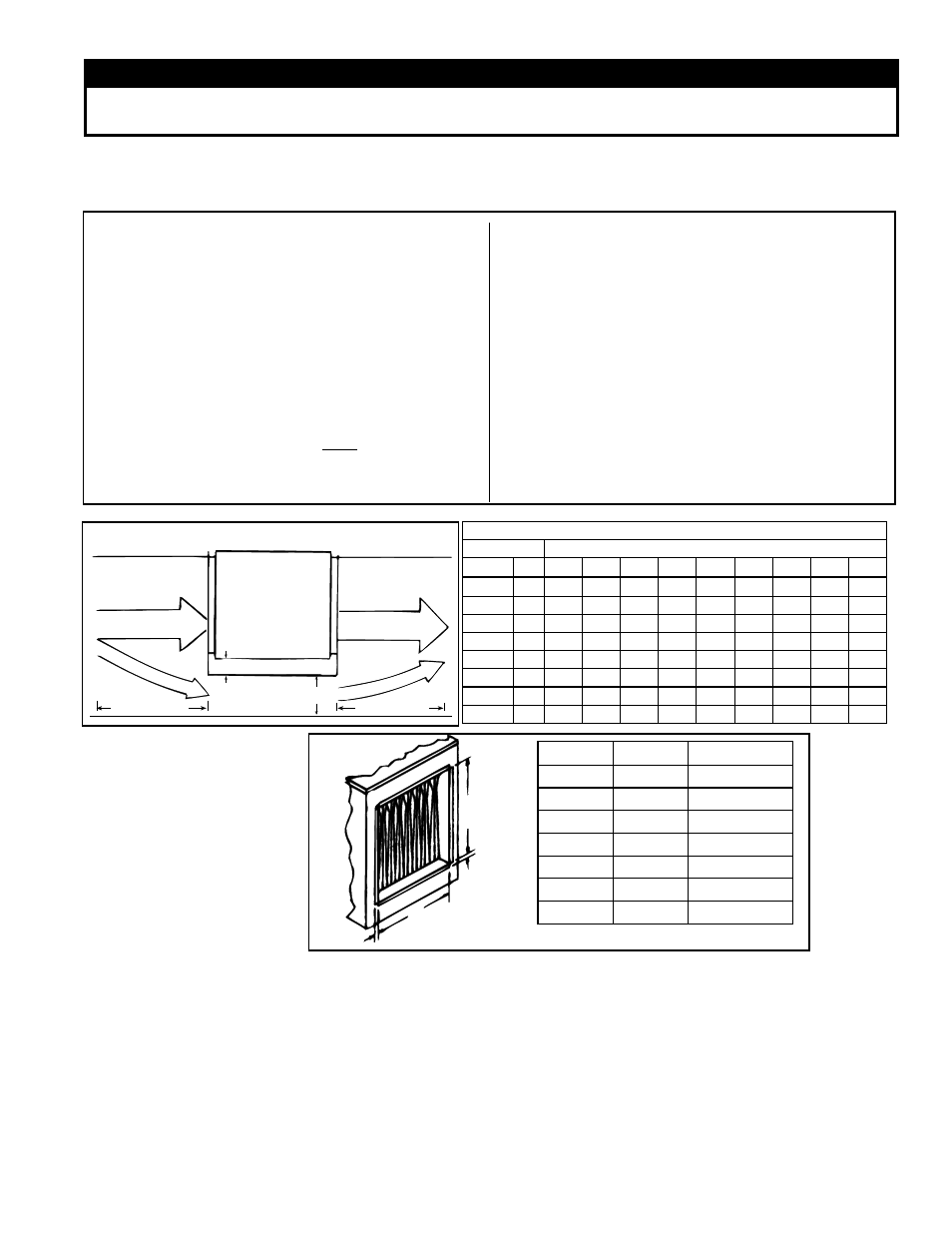

When the CFM of air throughput is greater than desirable or permissible for the unit,

a bypass duct may be constructed. Follow these instructions to determine the correct

size of the bypass duct.

6.3.3 Constructing a

Bypass Duct

Top View

of Furnace

Control Side

Bypass Duct A

2 (51mm) minimum

18 (457mm)

18 (457mm)

FIGURE 7 - Bypass Duct

Bypass CFM

"A" Width

Pressure Drop through the Furnace

inches mm

0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

3"

76

490 530 610 700 780 830 900 960 1010

4"

102 630 750 870 980 1090 1160 1250 1310 1400

5"

127 850 1010 1190 1300 1410 1520 1640 1730 1810

6"

152 1050 1290 1480 1650 1800 1940 2090 2200 2320

7"

178 1250 1510 1760 1960 2180 2320 2500 2650 2800

8"

203 1490 1810 2100 2350 2560 2760 2940 3110 3290

9"

229 1700 2100 2400 2700 2970 3200 3400 3600 3800

10"

254 1920 2350 2760 3090 3650 4020 4300 4550 4800

Directions for Sizing Bypass Duct

1) From the tables in on page 10, find the pressure drop

(P.D.) and the allowable CFM for the furnace that is

being installed.

Example: Standard Size RP150 @ 50°F temperature

rise - P.D. .38; CFM 2210

2) Subtract the allowable CFM from the actual CFM of

the installation to determine how much air must be

diverted through the bypass duct.

Example: Blower CFM 3000

Allowable CFM -2210

Bypass CFM 790

3) Go to the column in the Bypass CFM Chart that is

closest to the pressure drop through the heater. Move

down in that column until you find the CFM closest to

the answer in Step 2).

Example: P.D. .40; Bypass CFM 900

4) Move to the left column to find out the required size

of the bypass duct.

Example: Bypass Duct Size is 3"

Depth of the bypass duct is 18" on both inlet and outlet

ends. Bypass duct must be located on side opposite

controls and 2" from the heat exchanger side panel.

NOTE: Not all capacities are covered in this chart. If

your installation is not covered, the correct size may be

determined by consulting the factory representative.

6.3.4 Duct

Connections

G

3/4 (19)

3/4 (19)

18

(457)

RP

HRPD

G

75, 100

--

12-1/2 (318)

125

250

15-1/4 (387)

150, 175

300, 350

20-3/4 (527)

200, 225

400

26-1/4 (667)

250, 300

500, 600

34-1/2 (876)

350

700

40 (1016)

400

800

45-1/2 (1156)

FIGURE 8 - Duct

Connection

Dimensions for

Horizontal Discharge -

inches (mm)

WARNING

The furnace must be installed on the positive pressure side of the air-circulating blower.

See Hazard Levels, page 2.

Requirements and

Suggestions for

Connecting and

Installing Ducts

•

Type of Ductwork - The type of duct installation to be used depends in part on the

type of construction of the roof (whether wood joist, steelbar joist, steel truss, pre-

cast concrete) and the ceiling (hung, flush, etc.).

•

Ductwork Material - Rectangular duct should be constructed of not lighter than

No. 26 U.S. gauge galvanized iron or No. 24 B & S gauge aluminum.

•

Ductwork Structure - All duct sections 24 inches (610mm) or wider, and over 48

inches (1219mm) in length, should be cross broken on top and bottom and should

have standing seams or angle-iron braces. Joints should be S and drive strip, or

locked.

•

Through Masonry Walls - No warm air duct should come in contact with masonry

walls. Insulate around all air duct through masonry walls with not less than 1/2" (1"

recommended) of insulation.