0 mechanical (cont'd), 1 gas piping and pressures (cont'd) – Reznor HRPD (Outdoor Duct Furnaces) Unit Installation Manual User Manual

Page 8

Form I-RP/HRPD, P/N 132210 R14, Page 8

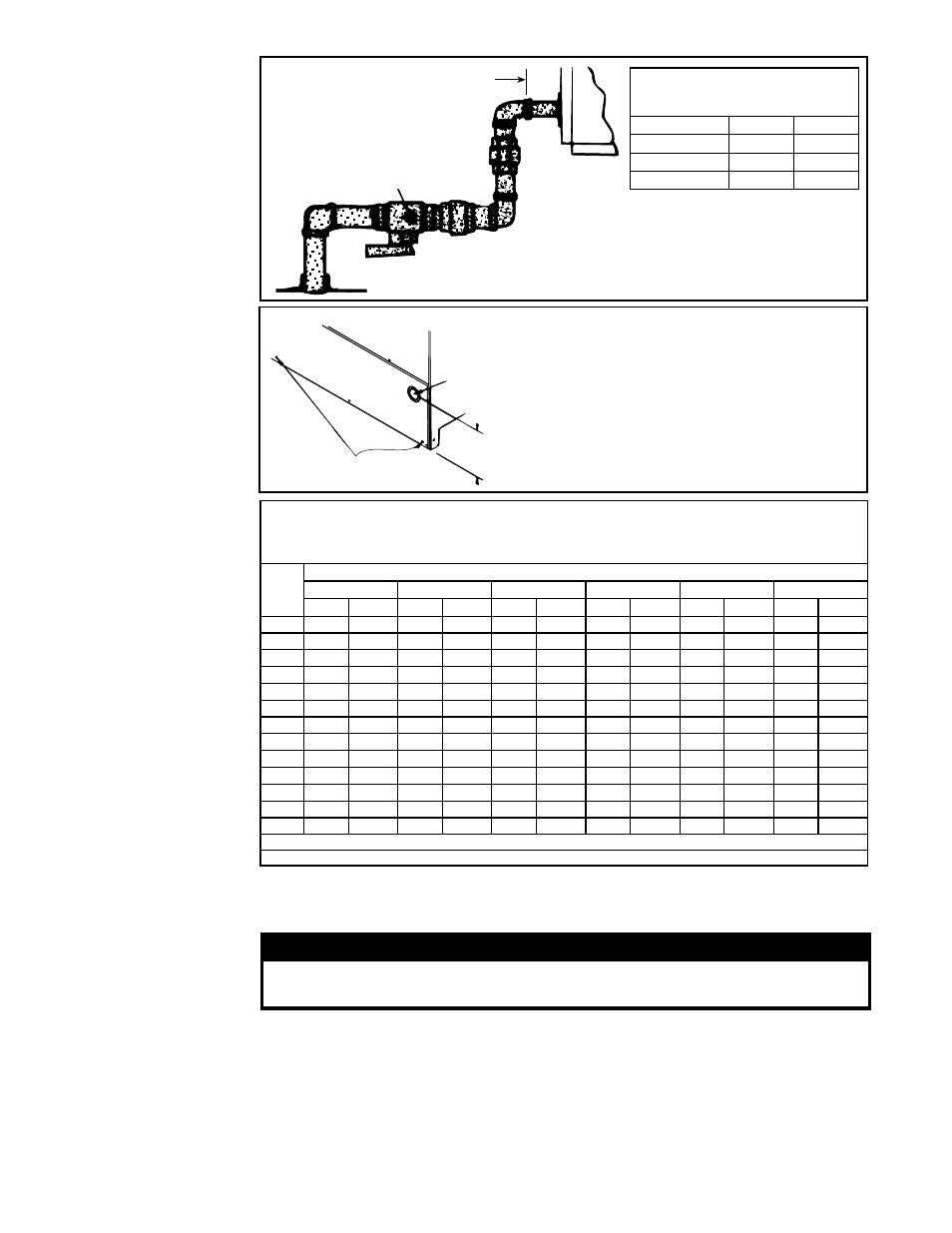

Minimum 1 (25mm) clearance

between heater access panel

and elbow or fitting

Install a 1/8 NPT plug

with tap for test gauge

immediately upstream

of the gas supply

connection.

Manual shutoff valve

Installer supplies

manual shutoff,

ground unions

and shaded piping

FIGURE 4A -

Gas Connection

Requirements

Gas Supply Sizing

Measuring manifold gas pressure cannot be done until the heater is in operation. It is

included in the steps of the "Check-Test-Start" procedure in Paragraph 9.0 The following

warnings and instructions apply.

WARNING

Manifold gas pressure must never exceed 3.5" w.c. for natural gas

and 10" w.c. for propane gas.

For Natural Gas: When the heater leaves the factory, the combination valve is set so that

the outlet gas pressure of a single-stage valve or high fire of a two-stage valve is regulated

to 3.5" w.c. Low fire on a two-stage valve is set to 1.8" w.c. Inlet supply pressure to the

valve must be a minimum of 5" w.c. or

as noted on the rating plate and a maximum of

14" w.c.

NOTE: Always check the rating plate for minimum gas supply pressure.

Minimum supply pressure requirements vary based on size of burner and the gas control

option. Most units require a minimum of 5" w.c. of natural gas as stated above, but Sizes

350 and 400 with electronic modulation require a minimum of 6" w.c. natural gas supply

pressure. Sizes 300 and 350 with mechanical modulation require 7" w.c.

FIGURE 4B - Gas

Connection Location

- Model Series RP

and HRPD (Multiple

furnaces require

one connection;

see FIGURE 2B

for approximate

location.)

Gas Supply

Entrance

5

-3/4

(146mm)

Condensate

Weep Holes

Install the gas supply piping so that

when the union is disconnected, the

supply pipe will not interfere with

the removal of the burner rack. (The

burner rack slides out of the control

side of the furnace.)

Manifold or Orifice

(Valve Outlet)

Pressure Settings

6.0 Mechanical

(cont'd)

6.1 Gas Piping

and Pressures

(cont'd)

Gas Connection to Single-Stage

Valve (Not Gas Supply Line Size)

RP

75-250 300-400

HRPD

250-500 600-800

Natural Gas

1/2"

3/4"

Propane

1/2"

1/2"

Capacity of Piping

Cubic Feet per Hour based on 0.3" w.c. Pressure Drop

Specific Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specific Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Length

Diameter of Pipe

of

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

Pipe

Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

20'

92

56

190

116

350

214

730

445

1100

671

2100

1281

30'

73

45

152

93

285

174

590

360

890

543

1650

1007

40'

63

38

130

79

245

149

500

305

760

464

1450

885

50'

56

34

115

70

215

131

440

268

670

409

1270

775

60'

50

31

105

64

195

119

400

244

610

372

1105

674

70'

46

28

96

59

180

110

370

226

560

342

1050

641

80'

43

26

90

55

170

104

350

214

530

323

990

604

90'

40

24

84

51

160

98

320

195

490

299

930

567

100'

38

23

79

48

150

92

305

186

460

281

870

531

125'

34

21

72

44

130

79

275

168

410

250

780

476

150'

31

19

64

39

120

73

250

153

380

232

710

433

175'

28

17

59

36

110

67

225

137

350

214

650

397

200'

26

16

55

34

100

61

210

128

320

195

610

372

Note: When sizing supply lines, consider possibilities of future expansion and increased requirements.

Refer to National Fuel Gas Code for additional information on line sizing.