Vsr-s, Vane type waterflow alarm switch with retard – Potter Releasing Systems User Manual

Page 94

94

PRINTED IN USA

MFG. #5401206 - REV G

12/08

VSR-S

VANE TYPE WATERFLOW

ALARM SWITCH WITH RETARD

FOR SMALL PIPE

PAGE 3 OF 3

Testing

The frequency of inspection and testing for the Model VSR-S and its

associated protective monitoring system should be in accordance with

applicable NFPA Codes and Standards and/or the authority having

jurisdiction (manufacturer recommends quarterly or more frequently.)

An inspector's test valve (usually located at the end of the most remote branch

line) should always be used for test purposes. If there are no provisions for

testing the operation of the flow detection device on the system, application

of the VSR-S is not recommended or advisable.

A minimum flow of 10 gpm (38 Lpm) is required to activate this device.

Please advise the person responsible for testing of the

fire protection system that this system must be tested in accordance with

the testing instructions.

Maintenance

Inspect detectors monthly for leaks. If leaks are found, replace the

detector. The VSR-S waterflow switch should provide years of trouble-

free service. The retard and switch assembly are easily field replaceable.

In the unlikely event that either component does not perform properly,

please order replacement retard switch assembly stock #1029030. There

is no maintenance required, only periodic testing and inspection.

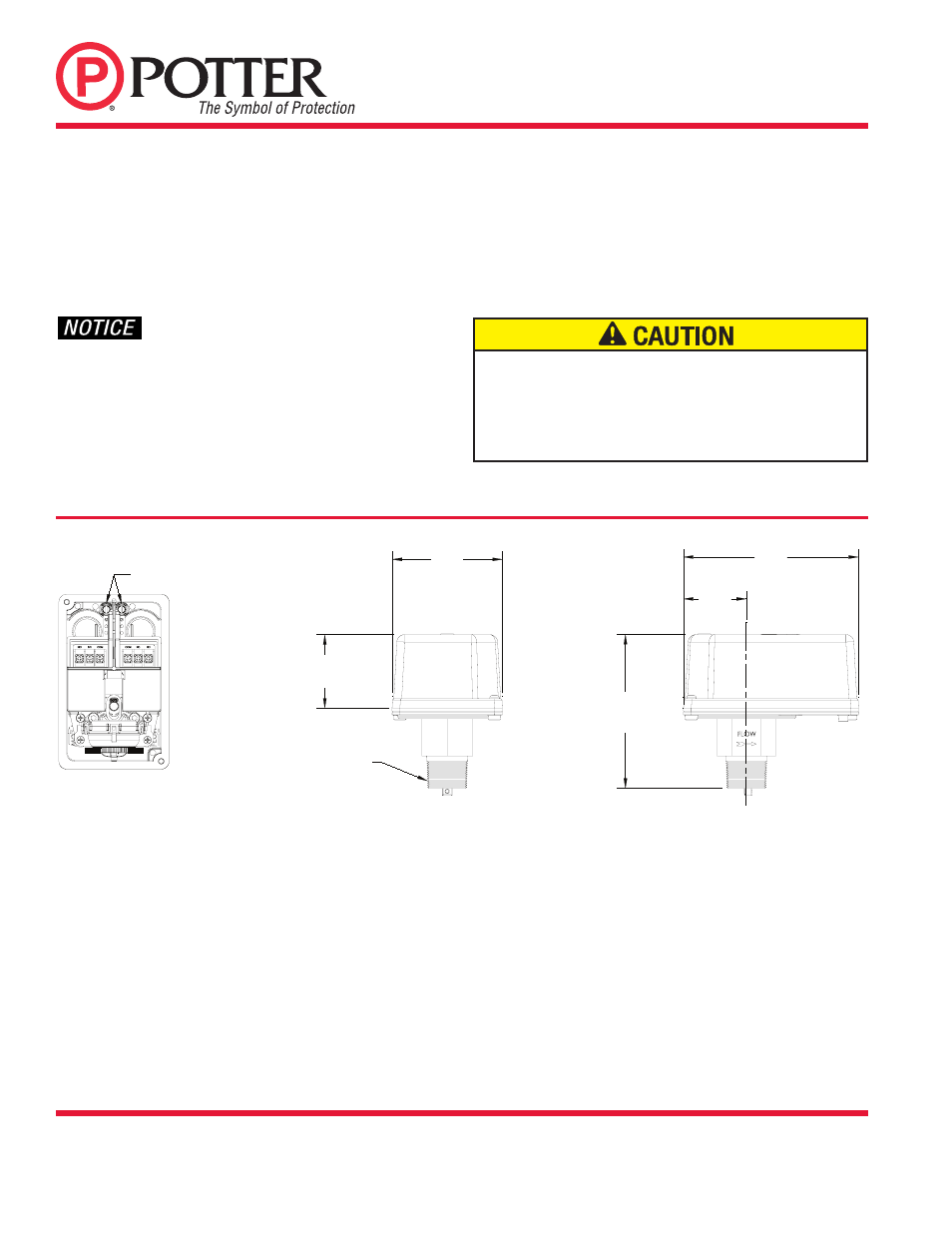

DWG# 1206-5

GROUND SCREWS

3.50"

5.56"

(89.0 mm)

(59.4 mm)

2.34"

(141.2 mm)

(52.3 mm)

4.89"

2.00"

(50.8 mm)

1"-11 1/2 NPT

Mounting Dimensions

Waterflow switches that are monitoring wet pipe sprinkler systems

shall not be used as the sole initiating device to discharge AFFF,

deluge, or chemical suppression systems. Waterflow switches used

for this application may result in unintended discharges caused

by surges, trapped air, or short retard times.

Removal

• To prevent accidental water damage, all control valves should

be shut tight and the system completely drained before waterflow

detectors are removed or replaced.

• Turn off electrical power to the detector, then disconnect wiring.

• Use a wrench on the flats of the bushing. Turn the switch

counterclockwise to disengage the pipe threads.

• Gently lift with your fingers, roll the vane so it will fit through the

hole while continuing to lift the waterflow detector.

• Lift detector clear of pipe.