Potter Releasing Systems User Manual

Page 53

53

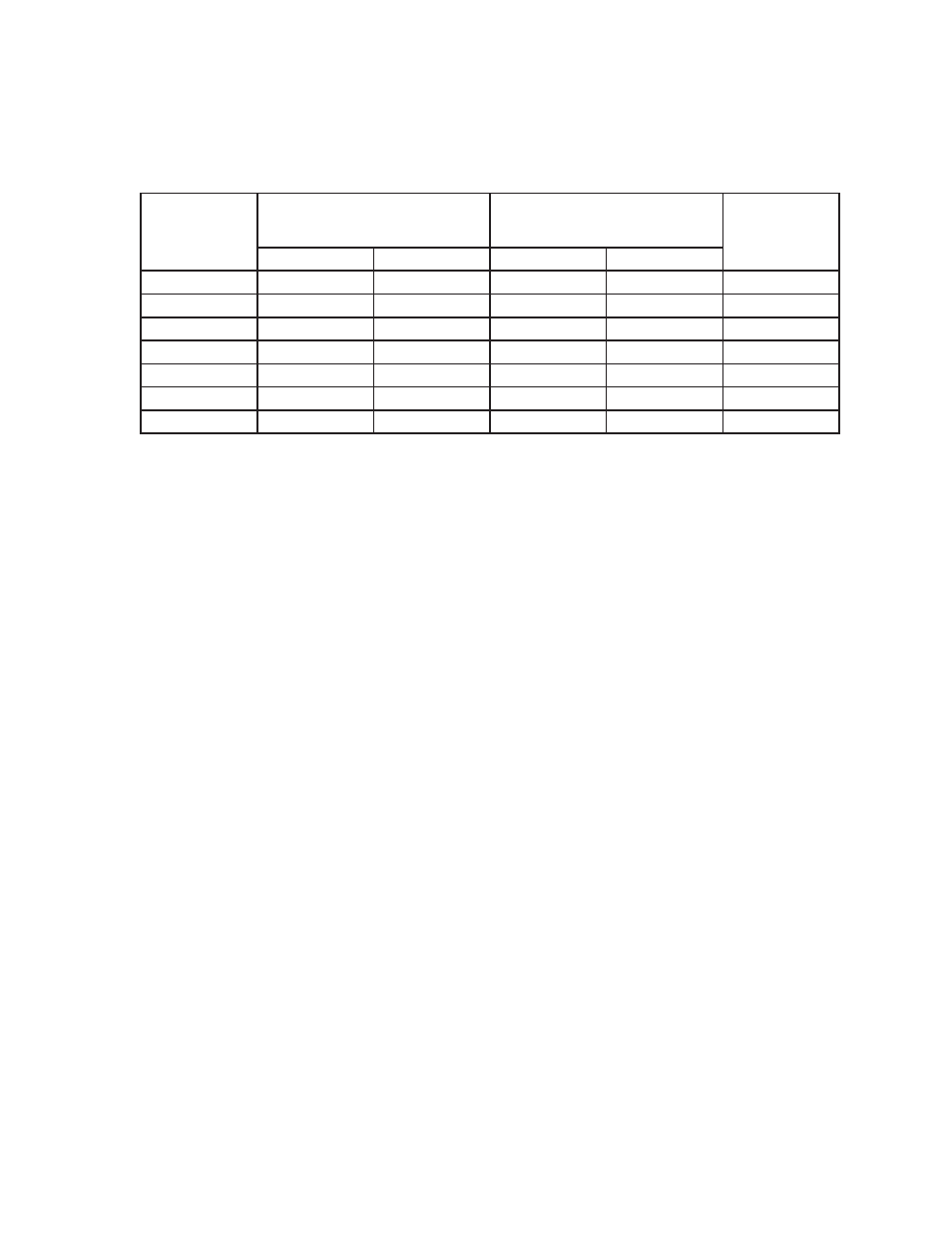

Temperature Classification for Heat-Sensing Fire Detectors NFPA 72, 2010 Table 17.6.2.1

Temperature

Classification

Temperature Rating Range

Maximum Ceiling Temperature

Color Code

°C

°F

°C

°F

low*

39-57

100-134

28

80

uncolored

ordinary

58-79

135-174

47

115

uncolored

intermediate

80-121

175-249

69

155

white

high

122-162

250-324

111

230

blue

extra high

163-204

325-399

152

305

red

very extra high

205-259

400-499

194

380

green

ultra high

260-302

500-575

249

480

orange

Note: The difference between the detectors rated temperature and the maximum ambient ceiling temperature

should be as small as possible to minimize response time.

* Intended only for installation in controlled ambient areas. Units shall be marked to indicate maximum

ambient installation termperature.

Release Systems General Information and Terminology

Single Zone Activation - Any single alarm condition will cause the release circuit to trip.

Cross Zone Activation - An alarm condition must be present on two or more zones simultaneously, before the

release circuit will be energized.

Note: Cross zoning is used to help prevent false activation of the release circuit by requiring two or more

detectors on two or more zones to alarm. It is mainly used on deluge or dry chemical systems where accidental

discharge of the extinguishing agent must be prevented.

Or on double interlock systems where a smoke or heat detector must trip and a low air switch must also trip to

indicate a loss of air pressure in the system due to an open sprinkler.

Pre-Discharge Time - The time between when the panel detects an alarm and when the release circuit is activated.

Note: The pre-discharge time is generally an adjustable timer on the release panel. It is primarily used on

dry chemical systems. The purpose of the timer is to allow the appropriate personnel time to investigate the

situation, or to allow people to evacuate the area and shut the doors before the chemical is released.

Discharge Time - The amount of time the release panel will energize the solenoid. If there is any doubt as

to the amount of time this should be programmed for, set it for continuous. This will prevent the valve from

accidently slamming shut due to a momentary drop in water pressure. In the case of a double interlock system,

it will insure that the valve will open regardless of the amount of time between when the panel detects an alarm,

and a sprinkler opens to remove pressure from the system.

Suppression systems or groups of systems shall be controlled by a single control unit that monitors the

associated initiating device(s), actuates the associated releasing device(s), and controls the associated agent

release notification appliances. If the releasing control unit is located in a protected premises having a separate

fire alarm system, it shall be monitored for alarm, supervisory, and trouble signals, but shall not be dependent on

or affected by the operation or failure of the protected premises fire alarm system.

Exception: If the configuration of multiple control units is listed for releasing device service, and if a trouble

condition or manual disconnect on either control unit causes a trouble or supervisory signal, the initiating

devices on one control unit shall be permitted to actuate releasing devices on another control unit.

NFPA 72, 2010 23.13.8 - 23.13.10 Water Flow Switch: PS10-1, PS10-2

Water flow switches on single or double interlock systems, or deluge systems must be a pressure type device.

The switch is installed in line with the intermediate chamber or alarm port. This section of piping may run to

a water motor gong or just to a drain. Under normal (no alarm) condition, there is no water or pressure in this