Pcvs-1, -2, Control valve supervisory switch – Potter Releasing Systems User Manual

Page 74

74

PAGE 2 OF 4

PCVS-1, -2

CONTROL VALVE

SUPERVISORY SWITCH

PRINTED IN USA

MFG. #5400980 - REV V

5/09

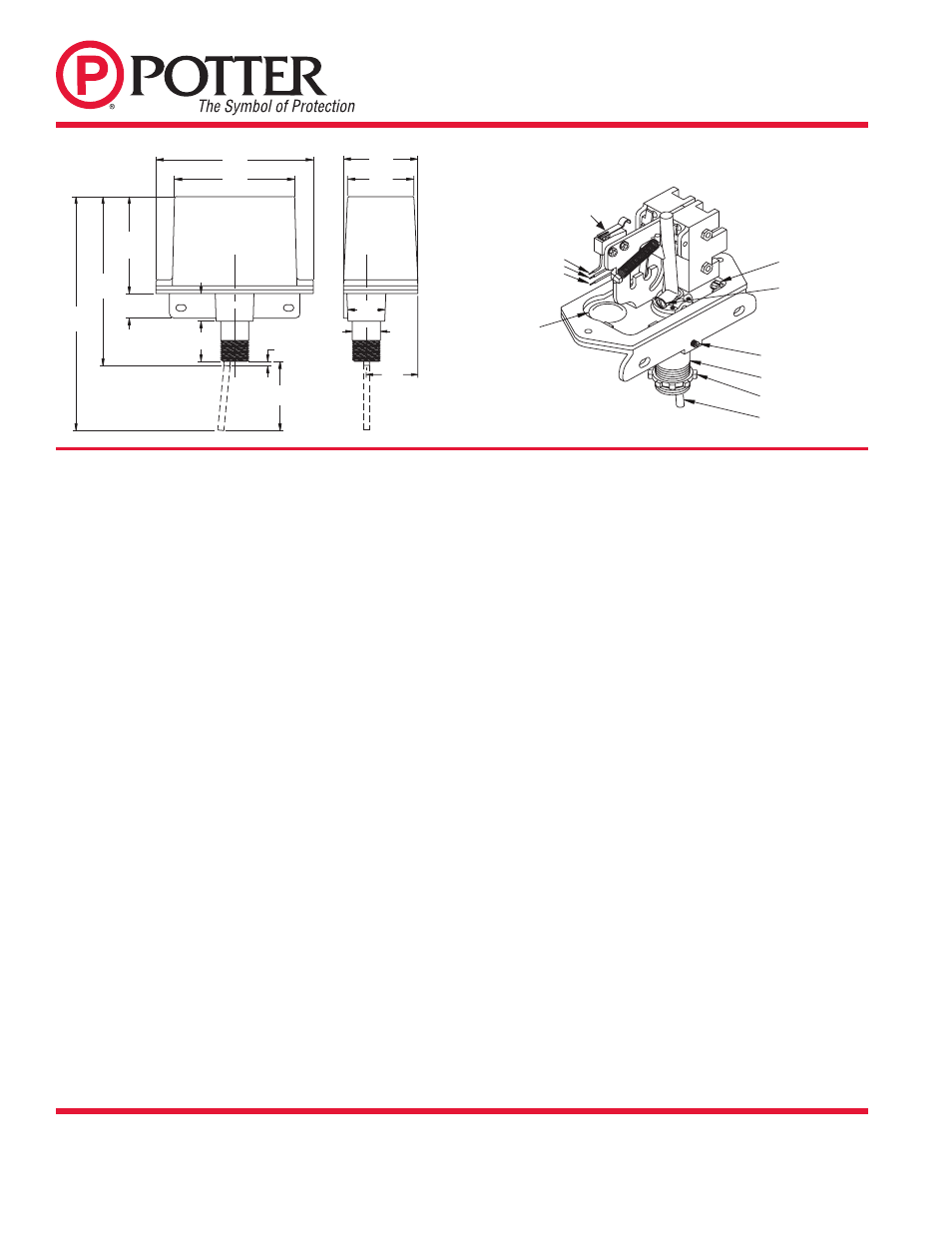

Fig. 1 Dimensions

Typical Installations On Post Indicator Valve Housings (See Figs. 3 Thru 6)

Refer to Fig. 2 for the location of parts described in the following instructions.

Note: If the sprinkler system is in service the owner or authorized representative

should be notified, before any work is done on the system, that the valve

controlling the water supply to the system may be closed for periods of time

during the installation and testing of this device, resulting in all or portions of

the system being inoperative during these periods.

If the system is not in service and valve is closed, be sure that opening the

valve will not allow any unwanted water flow due to openings in the system,

such as heads off, broken or incomplete piping, etc.

1. Position the valve to fully open (“OPEN” should appear in the window

of the housing). Partially close the valve while observing the direction

that the target assembly moves. Reopen the valve.

If the valve housing is predrilled with a 1/2" NPT for installation of a

monitoring switch, remove the 1/2" plug and fully open the valve. Make

sure that “OPEN” appears in the window of the housing. GO TO STEP

NO. 6.

2. Remove the head and target assembly (consultation with valve

manufacturer is recommended).

3. If the target assembly moved up as the valve was closed, measure the

distance from the bottom of the head to the lower part of the target

assembly that will contact the trip rod of the PCVS (see Fig. 3). This is

usually a plate or bar on the target assembly, on a side adjacent to the

“OPEN/SHUT” plates. Subtract 1/8" from the measurement.

If the target moved down as the valve was closed, measure the distance

from the bottom of the head to the upper portion of the target assembly

that will contact the trip rod of the PCVS (see Fig. 4). Add 1/8" (3,2mm)

to this measurement.

4. Mark the housing at the proper location. Using a 23/32" (18,2mm) drill

bit, drill and then tap a 1/2" NPT in the housing on the side that coincides

with the portion of the target assembly that will engage the trip rod of

the PCVS.

5. Replace the head and target assembly.

6. Loosen the socket head screw that holds the nipple in the PCVS and

remove the nipple.

7. Screw the locknut that is provided onto the nipple.

8. Screw the nipple into the 1/2" NPT hole in the valve housing - hand

tighten. Tighten the locknut against the valve housing to secure the nipple

firmly in place.

9. Insert a scale or probe thru the nipple to measure the distance from the

open end of the nipple to the target assembly. Subtract 1/2" (12,5mm)

from this measurement.

NOTE: In some cases, it may be necessary to attach an angle bracket

to the target assembly to engage the PCVS trip rod.

10. Using the special tool provided, loosen the two cover screws and remove

the cover from the PCVS.

11. Loosen the locking screw that holds the trip rod in place and adjust the

rod length, from the end of the collar to the end of the rod, using the

dimension determined in Step 9. Tighten the locking screw to hold the

rod in place.

NOTE: If trip rod length is excessive, loosen the locking screw and

remove the trip rod from the trip lever. Using pliers, break off the one

(1) inch long notched section (see Fig. 7). Reinstall trip rod and repeat

Step 11 procedure.

12. Partially close the valve (3 to 4 revolutions of the handle/hand wheel).

13. Slide the PCVS unit as far as possible onto the nipple, observing which

direction the rod will move when the valve is closed. Orient the device

to actuate the switches when the valve is open. Tighten the socket head

screw in the collar.

14. Carefully open the valve to the fully open position. As the target moves to

the open position it should engage the trip rod and actuate the switch(es).

There should be a minimum overtravel of 1/2 revolution of the handle/

hand wheel after the switch(es) actuate (a continuity meter connected

to each set of contacts is one method that could be used to determine

this).

15. Slowly close the valve. The switch must operate during the first two

revolutions of the handle/hand wheel or during 1/5 of the travel distance

of the valve control apparatus from its normal condition.

NOTE: Small adjustments of the target position may be necessary

(consultation with valve manufacturer is recommended).

16. Complete the required electrical wiring, connections and tests. The

valve should be operated through the entire cycle of fully closed and

fully open to determine the integrity of the PCVS installation and the

signaling system. Check that all electrical and mechanical connections

are secure.

17. When the installation and testing are complete, return valve to its proper

position.

18. Alternative installation for other post indicator valve housing shown in

Fig. 5 and 6.

Fig. 2 Parts

(WHITE) COM.

(WHITE) COM.

(RED) N.O.

BLACK N.C.

KNOCKOUTS FOR

ELECTRICAL

CONNECTIONS

DWG# 980-2

TRIP ROD

LOCKNUT

NIPPLE

SOCKET HEAD

SCREW

TRIP ROD

LOCKING

SCREW

GROUND SCREW

4.75

(12,1cm)

3.62

(9,2cm)

2.25

(5,7cm)

2,00

(12,1cm)

3.00

(7,6cm)

5.20

(13,2cm)

8.20

(20,8cm)

.75

(1,9cm)

.85

(2,2cm)

1.20

(3,0cm)

.12

(0,30cm)

3.12

(7,9cm)

ROD EXTENDED

ROD RETRACTED AND

BREAKAWAY SECTION

REMOVED

1.12

(2.8cm)

.85

(2,2cm)

1.56

(4,0cm)

DWG# 980-1

COVER TAMPER

SWITCH (OPTIONAL)