Rbvs, Universal ball valve switch – Potter Releasing Systems User Manual

Page 87

87

PRINTED IN USA

RBVS

UNIVERSAL BALL

VALVE SWITCH

MFG.# 5401086 - REV V

5/09

PAGE 2 OF 2

OUTGOING

INCOM

ING

DWG# 923-3

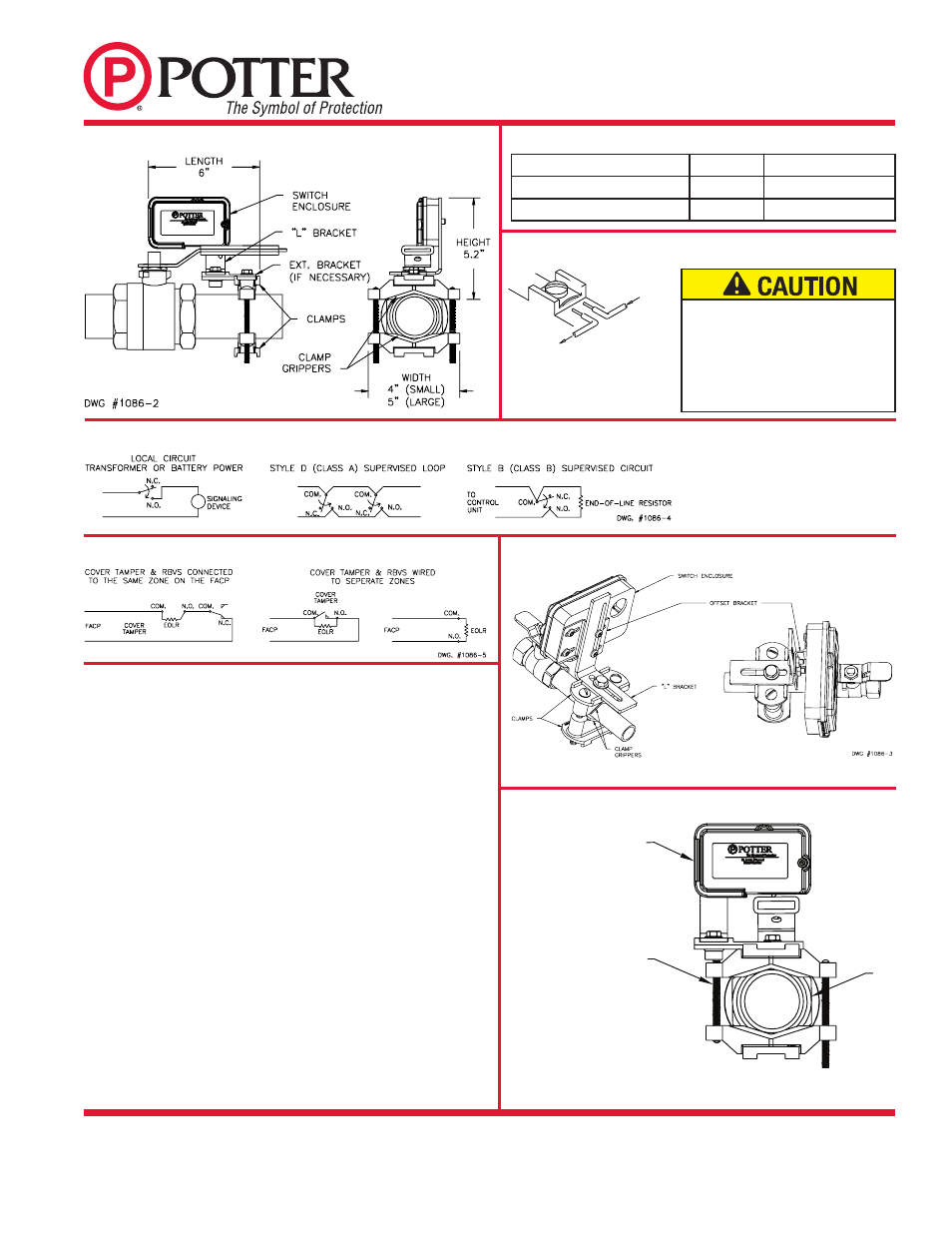

Installation on Tee Handle (See Fig. 3)

1. Select clamps and clamping bolts based upon pipe/valve size, see Table 1.

2. Insert rubber clamp grippers into clamps, See Fig. 3.

3. Place one clamp on top of pipe/ball valve near the valve handle and

insert clamping bolts through it.

4. Place other clamp over clamping bolts from beneath the installation

and thread hex nuts onto the clamping bolts, but do not fully tighten,

(be sure hex nuts seat properly in clamp hex recesses).

5. Loosely attach "L" bracket to the "offset" bracket and "offset"

bracket to the RBVS housing.

6. Be sure ball valve is in the fully open position.

7. Slide loosely assembled RBVS switch enclosure to a position that

permits the switch button to contact the valve handle approximately

1/2" from the end of the handle. Cut and remove the plastic coating

from the ball valve handle to allow the RBVS switch button to contact

(and be activated by) the metal of the handle.

8. Tighten clamping screws alternately and ¼-20 X ¾" bolt to 30 in-lbs.

(minimum) of torque.

9. With the valve handle fully open, slide the RBVS housing down

until the switch operates plus 1/8 inch. Tighten the screws holding

the RBVS to the "offset" bracket.

10. Remove the RBVS switch enclosure cover.

11. Close and open the valve to verify operation. The actuator should

easily retract up when the valve handle is in the open position.

12. Fully open the valve.

13. Wire main switch and tamper switch (if applicable). Carefully route

tamper switch wires through strain relief channel in switch enclosure.

Fully seat the wires into the bottom of the channel. See Fig. 1.

14. Replace RBVS switch enclosure cover and securely tighten cover screw.

Fig. 3

Typical Electrical Connections

Fig. 2 Typical Mounting Diagram

Tamper Switch Connections

Switch Terminal Connections, Clamping Plate Terminal

Table 1 Clamp Sizing

Fig. 4

SOME INSTALLATIONS MAY

CAUSE INTERFERENCE

BETWEEN MOUNTING BOLT AND

OFFSET BRACKET. INSTALL BOLT

FROM BOTTOM AND TRIM AS

NEEDED TO CORRECT.

RBVS

PIPE

DWG# 1086-6

Pipe Valve/Size

Clamp

Clamping Bolts

1/2" to 3/4" (12,5 to 19mm)

Small

10-32 x 2 1/2

1" to 2" (25 to 50mm)

Large

1/4-20 x 4"

An uninsulated section of single conductor

should not be looped around the terminal

and serve as two seperate connections. The

wire must be severed, thereby providing

supervision of the connection in the event

that the wire becomes dislodged from

under the terminal.