Flintec MCS-64 CANbus User Manual

Page 41

Manual MCS-64 Page 41

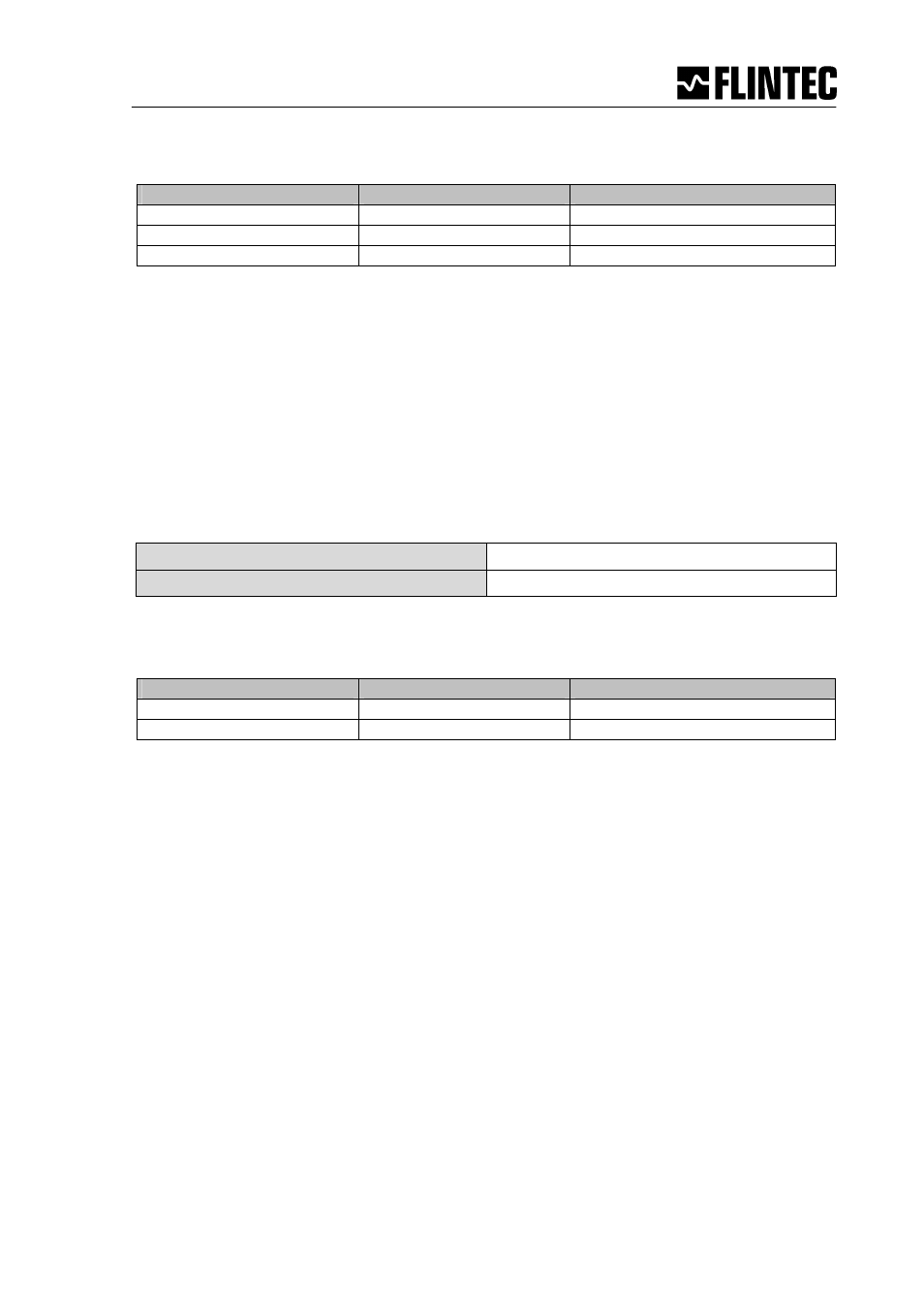

Request / Set Hysteresis value for setpoint 1

Master (PC / PLC) sends

Device responds

Result

H1 1-00100

Request: neg. Hysteresis

H1_100 OK

Setting: pos. Hysteresis

H1_-100 OK

Setting: neg. Hysteresis

Setpoint range between ± 1 (minimum) and ± 199999 (maximum).

Similarly to read or set the setpoint 1 hysteresis, use H2 instead of H1 etc.

( 2700sub02 )

.

A1

Request / Set the base for setpoint 1

[ 2800sub01 ]

The A1 command defines the base on which the setpoint value acts. If A1 is set to “0”

then setpoint 1 acts on the unfiltered gross weight. If A1 is set to “1” then setpoint 1 acts on

the unfiltered net weight.

A1 = 0

Not filtered gross weight

A1 = 1

Not filtered net weight

Request / Set base for setpoint 1

Master (PC / PLC) sends

Device responds

Result

A1 1+00000

Allocation gros weight

A1_1 OK

Allocation net weight

Similarly to read or set the setpoint 1 base, use A2 instead of A1 etc.

( 2800sub02 )

.

The MCS-64 transmits one TPDO2 every time a setpoint changes state. The weight sent in

the TPDO2 is the weight that caused the TPDO2 to be transmitted, Net or Gross as selected

for the actual setpoint. The TPDO2 also holds the Weighing status flags and the setpoint

Number.

If two (or more) setpoints have exactly the same settings the setpoint with the higher number

will be “hidden”.

NOTE:

All changes to the setpoint settings have to be stored in EEPROM using the SS

command. See section 4.11 page 47.