Flintec DAS 72.1 User Manual

Page 34

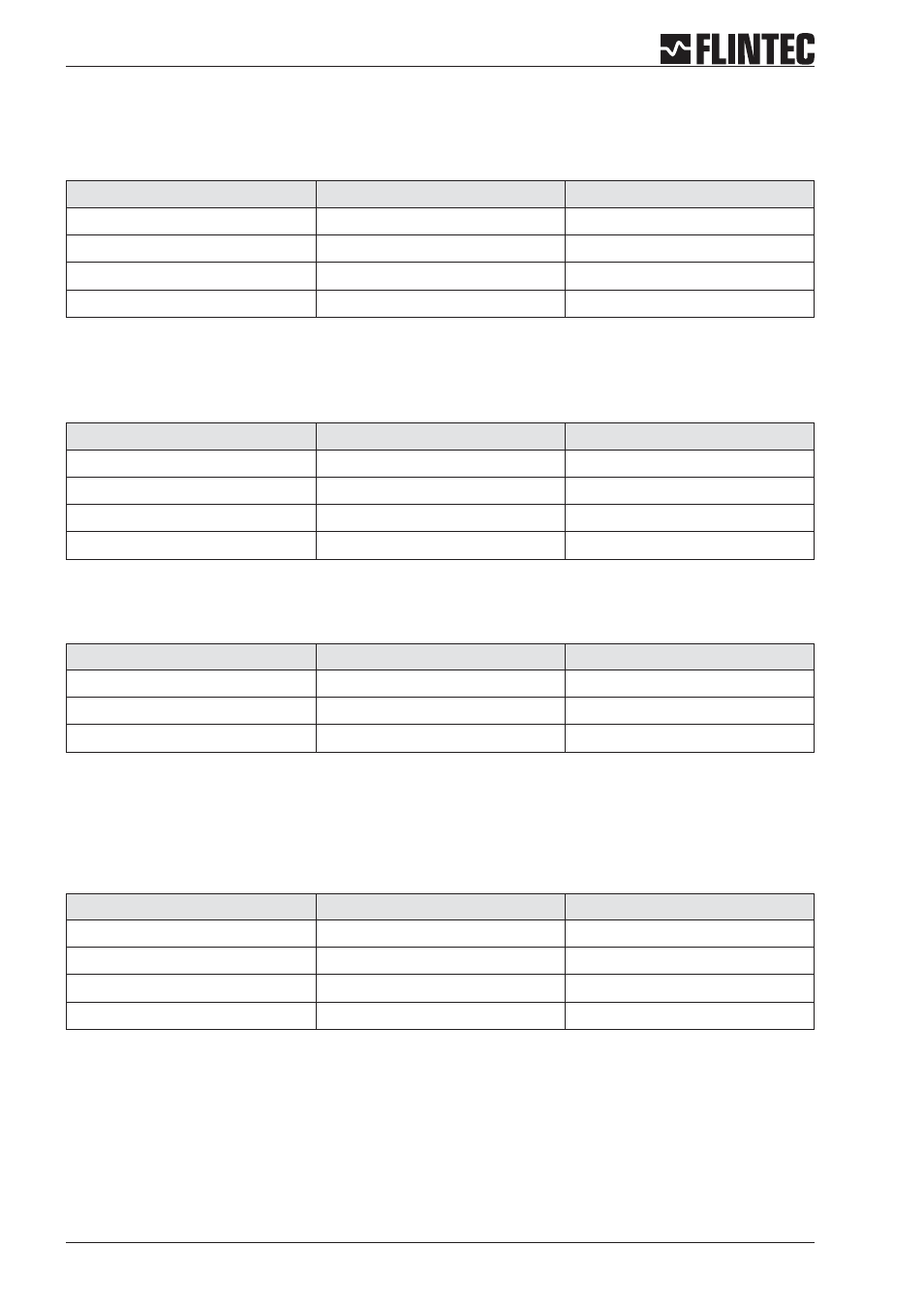

DS

Display step size

This command allows the output to step up or down by a unit other than 1. Permitted values are 1, 2, 5, 10,

20, 50, 100 and 200.

Master ( PC / PLC ) sends

DAS 72.1 responds

Result

DS

¿

S+00002

Request: display step size 2

CE

¿

E+00017 (example)

Request: TAC-counter CE17

CE_17

¿

OK

Calibration sequence active

DS_50

¿

OK

Setting: step size 50

DP

Set decimal point position

This command allows the decimal point to be positioned anywhere between leftmost and rightmost digits of

the 5-digit output result. Position 0 means no decimal point.

Master ( PC / PLC ) sends

DAS 72.1 responds

Result

DP

¿

P+00002

Request: position of decimal point

CE

¿

E+00017 (example)

Request: TAC-counter CE17

CE_17

¿

OK

Calibration sequence active

DP_0

¿

OK

Setting: no decimal point

CZ

Set calibration zero point

This is the reference point for all weight calculations, and is subject to TAC control.

Master ( PC / PLC ) sends

DAS 72.1 responds

Result

CE

¿

E+00017 (example)

Request: TAC-counter CE17

CE_17

¿

OK

Calibration sequence active

CZ

¿

OK

Zero point saved

Factory default: approx. 0 mV/V input signal

CG

Set calibration gain (span) value

This is the reference point for calibration under load, and is subject to TAC control.

Permitted values are 1 … 99 999.

Master ( PC / PLC ) sends

DAS 72.1 responds

Result

CG

¿

G+10000

Request: measuring range 10 000 d

CE

¿

E+00017 (example)

Request: TAC-counter CE17

CE_17

¿

OK

Calibration sequence active

CG_15000

¿

OK

Setting: span 15 000 d

For calibration an input signal near the display maximum (CM) will give the best system performance. The

minimum calibration load of at least 20% is recommended.

Factory default: 20 000 = 2,000 mV/V input signal

Page 34

Manual DAS 72.1