Checkline TI-UMX2 User Manual

Page 6

– 6 –

3.0 oVerVIeW

Turn the TI-UMX2 on and off using the switch located on the bottom right corner of

the keypad. When TI-UMX2 is initially turned on, a TI-UMX2 logo will be displayed,

accompaniedbylotsoflashingledlights.TheTI-UMX2willattemptto‘autoidentify’

thetransducertypethatisconnected,ordisplay‘NOPRB’ifthetransducercannotbe

identified. The following sections outline each scenario. Note: This section is primarily

written as a basic startup guide only.

3.1 TI-uMx2 displays

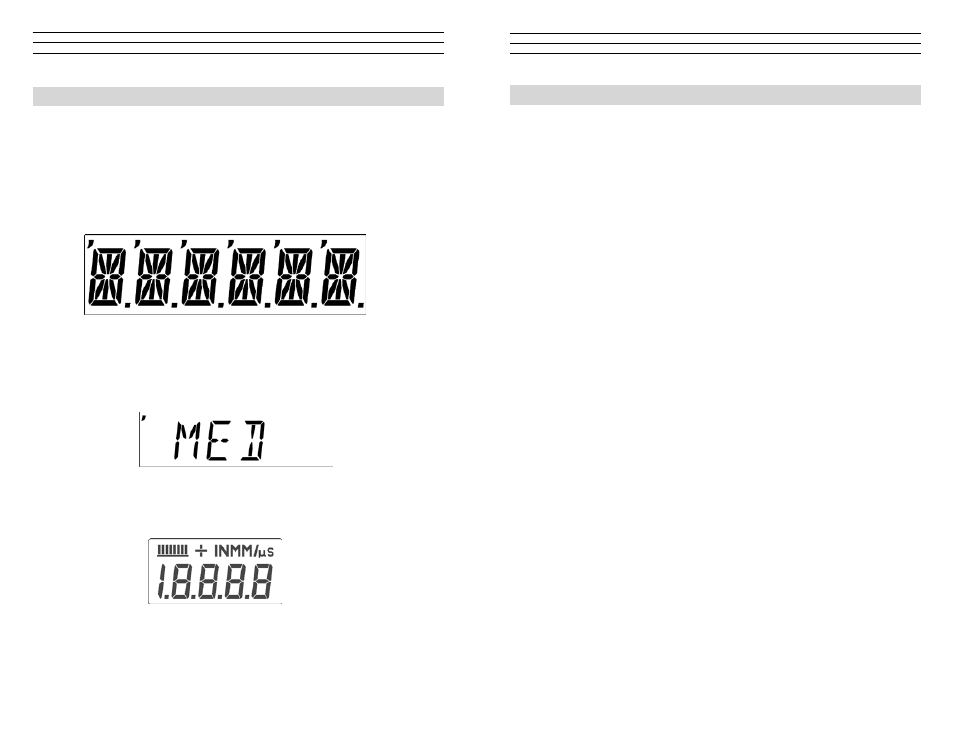

The TI-UMX2 is equipped with two segmented LCD displays that are used for entirely

different purposes. The 6 Character display above, is used for all the menu options and

any text to control the overall operation and functionality of the TI-UMX2. Since the

TI-UMX2 has the ability to store measurements, this display is also used to view and

movetospeciiccell/storagelocationsinthegridstoragestructureofthegauge.

noTe:

Theleftmost‘comma’locatedinthetopleftcornerofthedisplay,identiies

which sub menu feature option is currently selected, as shown above. In this example

the gain is currently set to medium.

The 4 digit display illustrated above, is considered the primary measurement display of

the TI-UMX2. The following outlines the measurement display:

4-digit, 8 Segment CLD Display

– 51 –

14.0 Care & MaInTenanCe

The TI-UMX2 housing is made of a clear PVC material that is very durable and well

suited for this application given the following conditions are followed:

• KeeptheTI-UMX2outofdirectsunlightasmuchaspossibletoavoidanypotential

‘crazing’orstresscracking,aswellasdiscoloration.

• Protectthehousingfromimpact.

• Submergeorrinsetheenclosureandtransducersinfreshwaterfollowinguse.

• WarnInG: Do not exceed the depth limitation of 1000 ft. Failure adhere to this

warning may result in leakage, potential implosion and serious injury.

The housing is sealed by o-rings, one on each end cap, which require meticulous care. In

order to maintain a watertight seal, the o-rings and their mating surfaces must be clean,

free of foreign material, and lubricated with silicone grease.

IMPorTanT: The following procedure must be performed on the end cap o-rings

before each use:

1. Clean all old silicone grease from o-rings and mating surfaces using paper towels.

2. Inspect o-rings for foreign material (sand, seaweed, hair, etc.), cracks, cuts, soft

spots, or deformities. Replace o-ring if damaged. Inspect mating surfaces for

scratches, rough spots, dents, or cracks.

3. Apply thin, even coat of silicone grease to o-rings on each end cap using finger to

spread evenly. Inspect to be sure the o-ring has been properly fitted, and screw the

end cap back in place, until it has a nice snug fit.