Checkline TI-UMX2 User Manual

Page 24

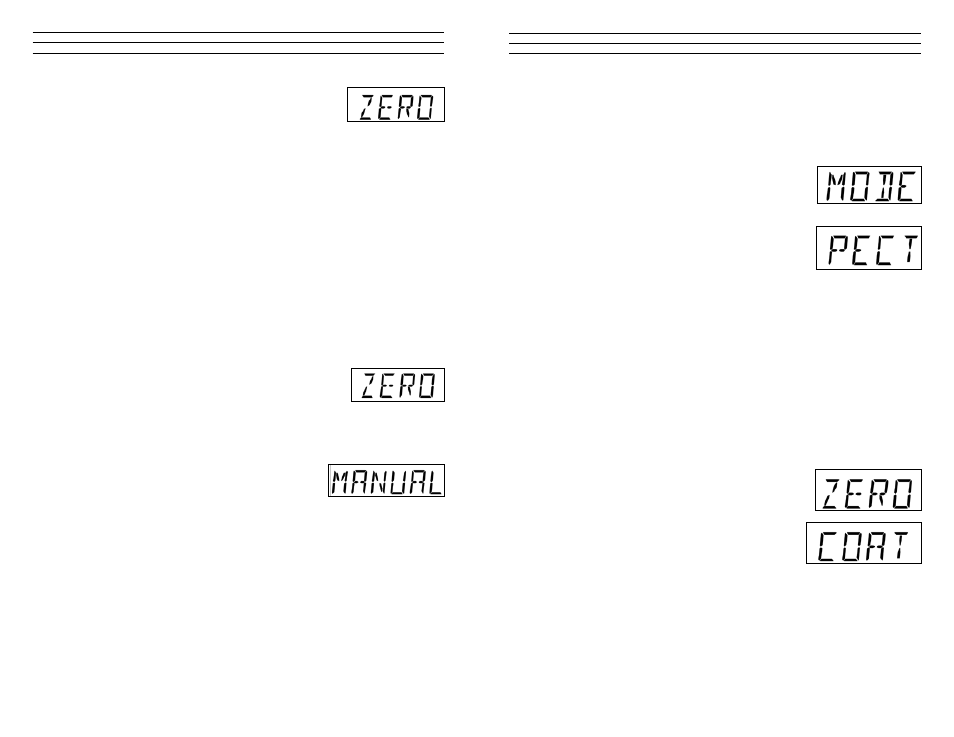

– 24 –

3. When Zero is displayed, immediately press and release

the button to enter the sub menu options. Again, the options

will begin scrolling in a continuous loop.

4. When auTo is displayed, immediately press and release the button to perform the

autozero.

5. Press and hold the button to escape out of the menu options at any time.

6. The TI-UMX2 in now ready to be calibrated for a given material type

Performing a Manual Probe Zero (On Block)

noTe

:Whenthemanualprobezerooptioniseitherpreferred,orneededtoresetthe

internalzerousedfortheautozero,the‘zerodisk’locatedonthebottomendcapofthe

TI-UMX2willbeusedasthezeroreferencestandard.

1. Press and hold the single TI-UMX2 button, located on the top end cap, until the top

level menu options begin scrolling on the alpha display. Once this occurs, the button

can now be released. The menu options will scroll one to the next in a time delayed

sequence, and will display all the menu options in a continuous loop.

2. When ZERO is displayed, immediately press and release the button to enter the sub

menu options. Again, the options will begin scrolling in a

continuous loop.

3. Apply a drop of couplant on the transducer and place the

transducerinsteadycontactwiththeprobezerodiskandobtainastablereading

onthemeasurementdisplay.Note:Donotremovethetransducerfromthezero

reference standard.

4. When MANUAL is displayed, immediately press and

releasethebuttontoperformamanualprobezero.

5. Press and hold the button to escape out of the menu

options at any time.

6. The TI-UMX2 in now ready to be calibrated for a given material type.

noTe: The value that is displayed will change depending on the current velocity setting

in the TI-UMX2. Disregard the number that is displayed. It is not important. What is

important is accurately performing the steps outlined above to insure reliability of the

probezerocalculation.

7.3 Material Calibration

In order for the TI-UMX2 to make accurate measurements, it must be set to the correct

sound velocity of the material being measured. Different types of materials have

– 33 –

Enabling PECT Mode

1. Press and hold the single TI-UMX2 button, located on the top end cap, until the top

level menu options begin scrolling on the alpha display. Once this occurs, the button

can now be released. The menu options will scroll one to the next in a time delayed

sequence, and will display all the menu options in a continuous loop.

2. When MODE is displayed, immediately press and release

the button to enter the sub menu options. Again, the

options will begin scrolling

in a continuous loop (P-E, PECT, E-E).

3. When the desired option is displayed, immediately press

and release the button to set the option in the TI-UMX2.

For this example, PECT has been selected.

4. Press and hold the button to escape out of the sub menu options at any time.

10.3 Zero Coating

In order to account for very slight electronic differences in transducers of the same type,

frequency,anddiameter,theTI-UMX2hasbeenequippedwitha“zerocoating”feature.

This enables the TI-UMX2 to obtain very accurate readings on coatings, eliminating

potential errors incurred from slight differences in the manufacturing processes. The

coatingzeroshouldbeperformedonanuncoatedsectionofthesamematerialor

something similar. The procedure is outlined below:

1. Press and hold the single TI-UMX2 button, located on the top end cap, until the top

level menu options begin scrolling on the alpha display. Once this occurs, the button

can now be released. The menu options will scroll one to the next in a time delayed

sequence, and will display all the menu options in a continuous loop.

2. When ZERO is displayed, immediately press and release

the button to enter the sub menu options. Again, the

options will begin scrolling in a continuous loop (AUTO,

MANUAL, COAT).

3. Apply a drop of couplant on the transducer or test

material. Place the transducer on an uncoated surface

of the material and obtain a stable measurement. Do

not remove the transducer.