Checkline TI-UMX2 User Manual

Page 25

– 25 –

different inherent sound velocities. For example, the velocity of sound through steel

is about 0.233 inches per microsecond, versus that of aluminum, which is about 0.248

inches per microsecond. If the gauge is not set to the correct sound velocity, all of the

measurements the gauge makes will be erroneous by some fixed percentage.

The TI-UMX2 has 8 preset material types with common fixed velocities to select

from. There is also 1 custom programmable velocity available for non-standard known

material velocities.

Basic Material Type

In order to calibrate the TI-UMX2 according to a specific material to be tested, the user

can select a basic material type from a list with approximate velocity values according

to various material types. It’s important to note that these velocities will not always be

an exact representation of the material being tested. They will typically be more than

adequateforongoing‘historical’materialdegradationinspections.Thefollowingisa

list of the preset materials, and the procedure to select and calibrate the TI-UMX2:

1. Press and hold the single TI-UMX2 button, located on the top end cap, until the top

level menu options begin scrolling on the alpha display. Once this occurs, the button

can now be released. The menu options will scroll one to the next in a time delayed

sequence, and will display all the menu options in a

continuous loop.

2. When MATL is displayed, immediately press and

release the button to enter the sub menu options. Again, the options will begin

scrolling in a continuous loop.

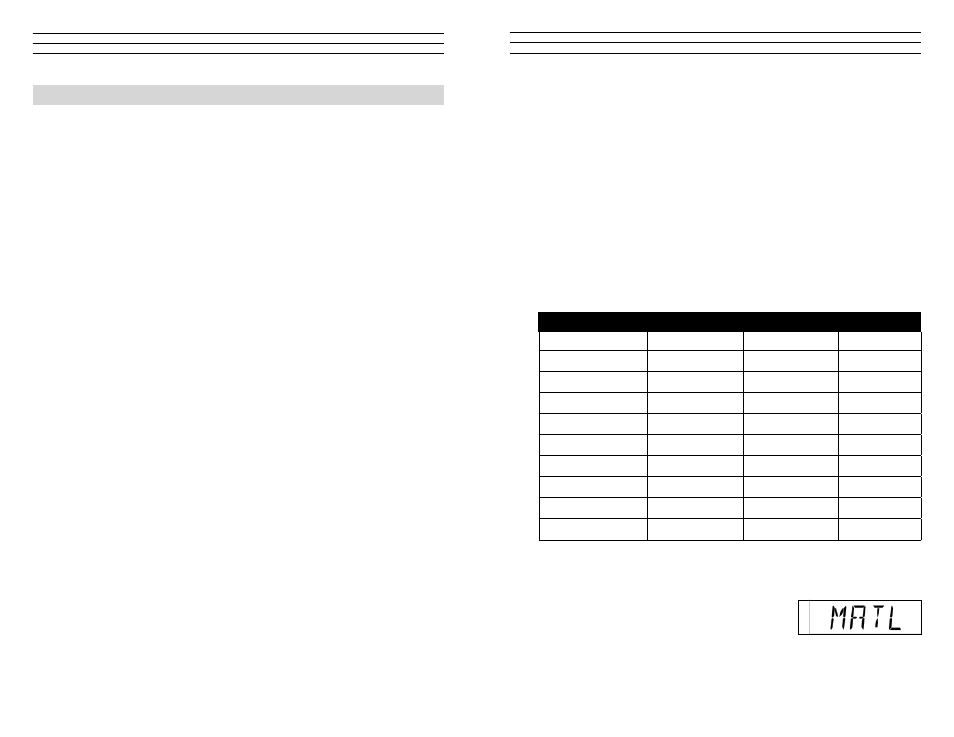

TI-UMX2 Material Chart

Material Types

Abbreviations

Velocity in/msec

Velocity m/sec

Aluminum

RLU

0.2500

6350

Steel (4340 Mild)

STL

0.2330

5918

Stainless Steel (304)

STLSTL

0.2229

5662

Iron

IRON

0.2320

5893

Cast Iron

CIRO

0.1800

4572

PVC

PVC

0.0940

2388

Polystyrene

PLST

0.0920

2337

Poly Urethane

PLUR

0.0700

1778

Custom

CUSTOM

USER

USER

–32 –

10.0 Pulse-eCHo CoaTInG & CoaTInG TeCHnIQues

10.1 Introduction to Pulse-echo Coating Measurement (PeCT)

In the previous sections we’ve discussed the need for detecting pits and flaws (pulse-

echo) in materials, along with the requirement to measure through and eliminate errors

caused by coated materials (echo-echo). Until now, both modes were needed in order

accomplish both tasks. Pulse-echo mode was used for flaw detection, and echo-echo

mode was used to eliminate the coating thickness and provide a nominal material

thickness only. With this in mind, it often became cumbersome toggling between both

modes respectively.

In a majority of applications involving coated materials, inspectors are often interested

in monitoring both the thickness of the material, as well as the thickness of the coating.

Therefore, the TI-UMX2 has been designed to provide the user with the ability to

measure the material and coating thicknesses simultaneously, while maintaining the

ability to detect flaws and pits all in a single mode called Pulse-Echo Coating (PECT).

Thisisaccomplishedbyusingacustomhybridcombinationmodeutilizingproperties

from the basic modes along with a group of special techniques and theoretical wave

phenomena’s.

TheTI-UMX2ispresettoacoatingvelocityof0.0850in/µsec(2159m/sec)fromthe

factory. This velocity is a very close approximation of the common coating velocities

foundintheield.However,thiscanbechangedtoanotherknowncoatingvelocity,

usingDataCommutilitysoftwaretoseta‘custom’velocitythatcanbeuploadedtothe

TI-UMX2.

10.2 enabling Pulse-echo Coating Mode (PeCT)

ThespecialPECTmodeisonlyavailableforusewith‘dualelement’transducers.When

the TI-UMX2 is initially powered up, the gauge will automatically check to see if the

transducerpluggedintothegaugecanberecognized.AllElectromaticEquipment

Company coating enabled transducers are equipped with the auto recognition feature. If

theTI-UMX2doesn’trecognizethataspecialcoatingenabledtransducerispluggedinto

the gauge, the coating feature will be disabled entirely. There are a number of coating

enabled transducers available from Dakota. Please contact us with your application

requirements for additional information on frequencies and diameters currently offered.

noTe: When PECT mode is used, the coating value cannot be viewed on the

TI-UMX2.Onlythebasematerialthicknessisdisplayed.However,ifthemeasurements

are stored to a file and downloaded to a PC, the coating measurements can be viewed

as they are saved within the file. The actual A-Scan waveform is also stored in the file.

This can prove very valuable, as it provides the inspector additional confidence that the

measurement was successful overall. Finally, all TI-UMX2 settings are also saved for

each individual reading, again offering confidence and detail for reporting

The following procedure demonstrates how to enable PECT mode: