2 error messages on the display of the k-375, Error messages on the display of the k-375 – BUCHI KjelSampler K-377 User Manual

Page 146

8 Troubleshooting

146

K-375/376/377 Operation Manual, Version B

8 .2

Error messages on the display of the K-375

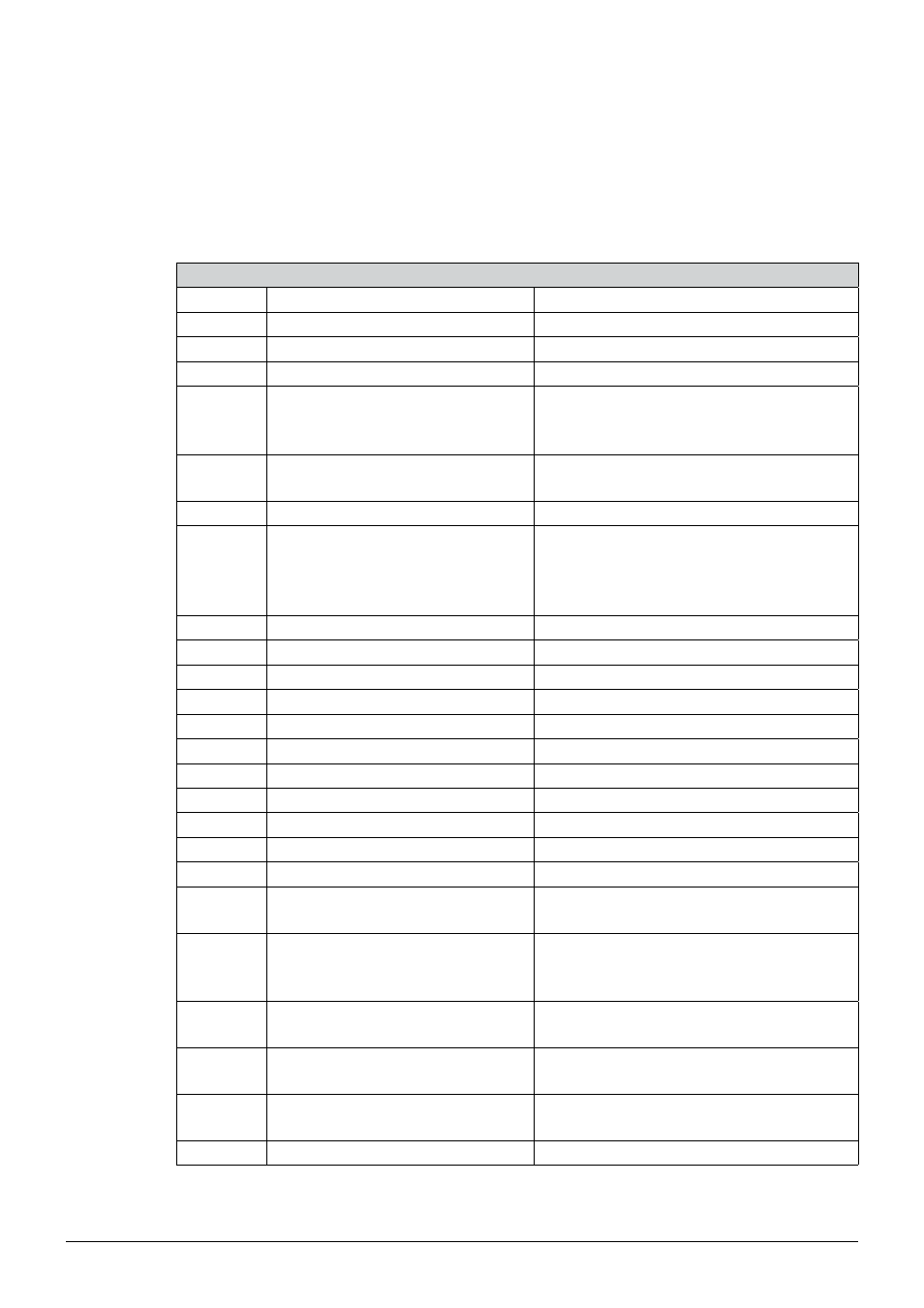

The error messages consist of an error number and a short text explaining the problem.

If the problem can’t be solved by the operator – please write down the error number and contact the

BUCHI service for further assistance.

K-375 Error Messages

Message ID

Description

Remedy

10’001

Process aborted by user

Restart process

10’002

Distillation starting point not found.

Check the electrode and try again

10’003

Last shutdown failed. Please make sure the

device is switched off by pushing the power

switch.

Use the power switch to turn off the instrument

10‘004

Method without aspiration. Aspiration

required with sampler.

Activate the aspiration

10‘005

Demo mode is activated.

Use Demo mode or switch to operating mode

10’011

Real time clock battery is low. Date and

time have been reset. Please set correct

date and time in settings. Change of battery

is recommended.

Exchange the battery

10’101

Door is open

Close the door

10’102

No sample tube present

Attach sample tube or adjust sample tube holder

10’103

Tube shield open

Close tube shield

10’104

Preheating recommended

Perform preheating

10’110

Buret disconnected

Connect buret

10’121

H2O tank empty

Fill up water

10’122

NaOH tank empty

Fill up sodium hydroxide

10’123

H3BO3 tank empty

Fill up boric acid

10’124

Waste receiver tank full

Empty tank

10’125

Waste sample tube tank full

Empty tank

10‘126

Acid tank empty

Fill up acid

10’200

Sensor ‘pump current’ out of order

Fault in current detection, AD-converter or other hard-

ware component. Call service.

10’204

Sensor ‘cooling water flow’ out of order

Fault in cooling water flow measurement,

AD-converter or other hardware component. Call

service.

10’208

Sensor ‘steam pressure’ out of order

Fault in steam pressure measurement, AD-converter

or other hardware component. Call service.

10’217

AD converter out of order

Fault in AD-converter or other hardware component.

Call service.

10’300

No cooling water flow detected. Please turn

on water tap.

Check cooling water supply. Turn on tap or chiller.

10‘301

Aspiration error: No vacuum detected

Check the system for leaks