2 cleaning the ph electrode, 3 replacing the buret – BUCHI KjelSampler K-377 User Manual

Page 139

7 Maintenance

139

K-375/376/377 Operation Manual, Version B

7 .7 .2

Cleaning the pH electrode

If the glass membrane or diaphragm are dirty, clean them to maintain the measuring function.

Depending on the degree of contamination, submerge only the glass membrane or the glass

membrane with the diaphragm into the cleaning solution.

Depending on the degree of contamination, the methods mentioned below are recommended.

After cleaning, rinse off the electrode with distilled water, condition it in electrolyte solution for 1 hour

or longer and recalibrate it prior to any further measurements.

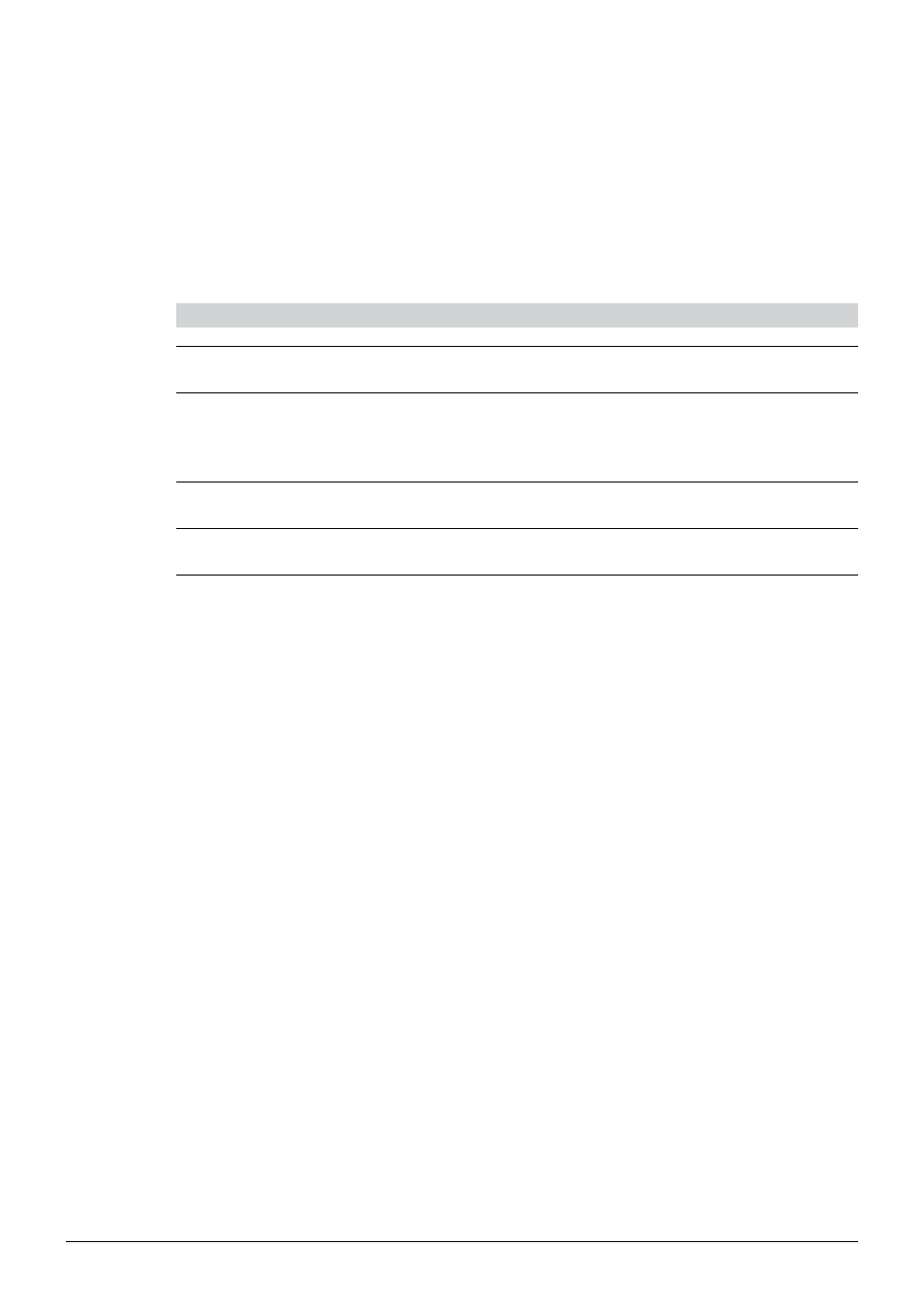

Table 7-1: Cleaning methods of the pH electrode

Soiling

Treatment

Comments

Inorganic substances

Several minutes, e. g. with

HCl 0.1 mol/L or NaOH 0.1 mol/L

Improved cleaning action with warm

solutions (40–50 °C)

Organic substances

(oil, grease, etc.)

Rinse off with a suitable organic

solvent (e.g. ethanol) or tenside

solution

For plastic shaft electrodes, take

chemical resistance into account.

Sensor can also be wiped off with a

soft, moistened cloth.

Proteins

Approx. 1 hour with pepsin/HCl

solution

5% pepsin in 0.1 mol/L HCl

Sulfides (on ceramic

diaphragm)

With thiourea/HCl solution (6.5 % in

HCl 0.1 mol/L ) up to discoloration

Cause: Reaction of electrolyte with

measuring solution.

7 .7 .3

Replacing the buret

As a rule, the need for replacing the buret occurs only rarely. It has to be replaced only as a result of

a defect.

7 .7 .4

Cleaning the splash protector and the rubber seal

In case the splash protector or the rubber seal is contaminated and this contamination was not

removed during the daily maintenance work, proceed as follows:

• Dismount the splash protector and remove the rubber seal.

• Rinse the splash protector with water to remove sample residues.

We recommend to replace the glass splash protector after approximately 3000 – 5000 determi-

nations, depending on the kind of application and frequency of maintenance. The plastic splash

protector can last more than 8000 distillations.

To prolong the lifetime of the seal, rinse it with water, especially if working with crystalline products.

Afterwards, dry it with a soft cloth, remount it and put the splash protector back in place.