4 troubleshooting – Cleveland Range inverter User Manual

Page 100

Chapter 6 - Troubleshooting & Maintenance

94

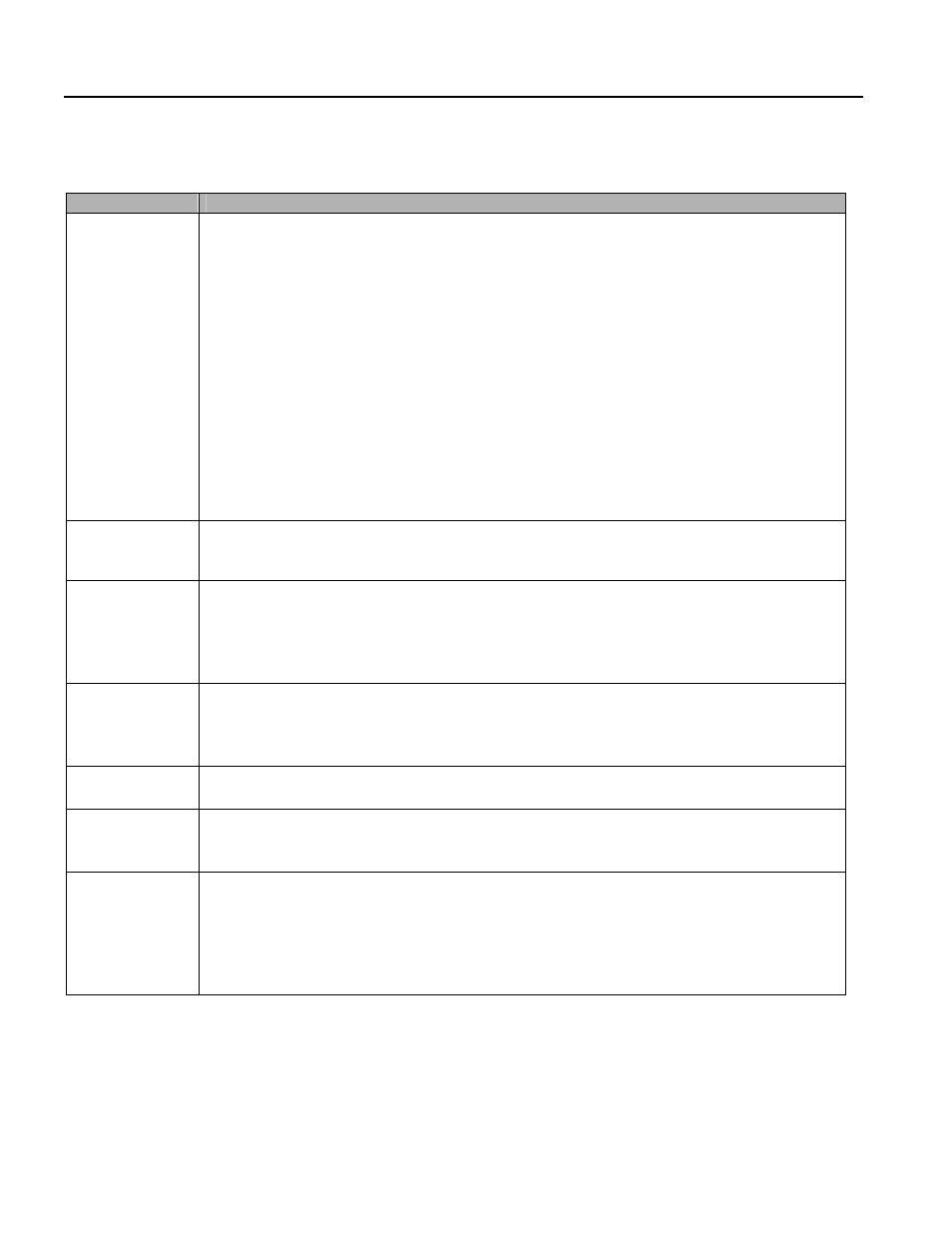

6.4 Troubleshooting

Condition

Check Point

The motor does

not rotate

1) Main circuit inspection

☞

Input (line) voltage normal? (LED charge lamp on?)

☞

Motor connected correctly?

2) Input signal inspection

☞

Input signal to inverter functioning?

☞

Forward and reverse signals inputted simultaneously to inverter?

☞

Inverter receiving command input frequency signal?

3) Parameter setting inspection

☞

Reverse prevention (FU1-03) function set?

☞

Operation mode (FU1-01) set correctly?

☞

Command frequency set to 0?

4) Load inspection

☞

Load too large, or motor restrained. (Mechanical Brake)

5) Other

☞

Alarm displayed on keypad, or alarm LED lit? (STOP LED blinking?)

The motor rotates

in opposite

directions

☞

Phase sequence of output terminal U, V and W correct?

☞

Starting signal (Forward/Reverse) connected correctly?

The difference

between the

rotating speed and

the reference is

too big

☞

Reference frequency verified? (Check the level of input signal)

☞

Following parameter setting verified?

Lower Limit Frequency (FU1-24), Upper Limit Frequency (FU1-25), Analog Frequency Gain (I/O-

1~10)

☞

External noise? (Use a shielded wire)

The inverter does

not accelerate or

decelerate

smoothly

☞

Acceleration/Deceleration time too short.

☞

Load too large?

☞

Torque Boost (FU1-27, 28) value too high? (Current limit function and the stall prevention

function verified?)

The motor current

is too high

☞

Load too large?

☞

Torque Boost Value (manual) too high?

The rotating

speed does not

increase

☞

Upper Limit Frequency (FU1-25) value correct?

☞

Load too large?

☞

Torque Boost (FU1-27, 28) value too high? Is Stall prevention function (FU1-59, 60) verified?

The rotating

speed oscillates

when the inverter

is operating.

1) Load inspection

☞

Load oscillating?

2) Input signal inspection

☞

Reference frequency signal oscillating?

3) Other

☞

Wiring too long? (Over 500m, 1,500ft)