Installation guidelines – Waterworks R.W. Atlas Exposed Thermostatic Valve with Metal Lever Handles User Manual

Page 3

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

RW ATLAS

Exposed Thermostatic Valve

INSTALLATION GUIDELINES

Page 3 of 4

8.10.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

RW ATLAS EXPOSED THERMOSTATIC VALVE WITH METAL WHEEL HANDLE (STYLE# RWXS01)

& METAL LEVER HANDLE (STYLE # RWXS10)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

FLUSH OUT THE SYSTEM:

¾ Wall valves and/or diverters and all shower fittings,

must be fully plumbed and installed prior to flushing

the system. (ALL SOLD SEPARATELY).

¾ The supply lines must be flushed out to prevent

clogging of the filter screens. Failure to flush the

lines will permanently damage the cartridge and

void the warranty.

¾ See Figure - 03 for Steps 14-18.

14. The exposed wall valve comes pre-installed with the

flush plate and is ready for flushing the lines.

15. Remove the showerhead and/or handshower (any

fitting with a flow regulator).

16. Turn on the water supply to flush out the lines, then

inspect all connections for leaks.

17. After the lines are flushed, turn off the water supply

and remove the flush plate.

18. Install the cartridge using the 2 cover screws and

turn the service stops off.

Figure - 03

FLUSH PLATE

SCREW

CARTRIDGE

SERVICE

STOP

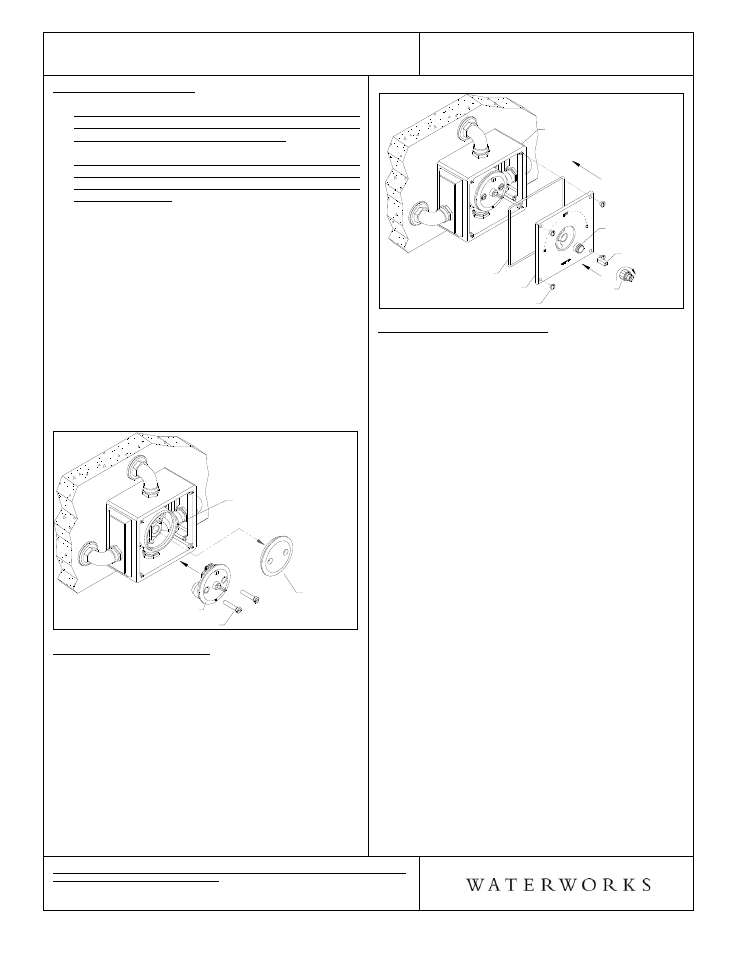

TRIM PLATE INSTALLATION:

¾ See Figure - 04 for steps 19 - 21.

19. Attach trim plate to valve body using the 4 screws,

making sure the gasket is behind the plate. Note:

USE A LARGE SLOTTED SCREWDRIVER TO AVOID

DAMAGING SCREWS.

20. Thread the all thread adapter onto the cartridge

until it stops and insert the square tube over the

cartridge stem.

21. Thread the trim nut onto the all thread adapter until

it stops. Note: DO NOT OVER-TIGHTEN.

Figure - 04

GASKET

TRIM NUT

ADAPTER

ALL THREAD

ADAPTER

SQUARE TUBE

TRIM PLATE

SCREW

VALVE BODY

TEMPERATURE CALIBRATION:

¾ The risk of scalding exists until the installer has

properly calibrated the temperature setting.

¾ See Figure - 05 for steps 22 - 26.

22. Turn on the water supply and a wall valve to run

water through the valve and insert a bladed screw

driver into the square tube.

23. Slowly rotate the square tube clockwise to attain full

cold, then rotate it counter-clockwise to attain full

hot. Verify a full range of temperature exists. Note: It

is approximately 2 complete rotations from full cold

to full hot.

24. With water running, rotate the square tube to adjust

the temperature to the maximum desired bathing

temperature, verified with a thermometer. Turn the

water off and make sure not to change this

temperature setting.

25. Unthread the handle assembly from the limit stop

assembly and loosen the 4 set screws on the limit

stop.

26. Insert the limit stop assembly onto the trim nut

making sure the limit stop pin (shown removed)

makes contact with the limit stop on the trim plate,

then tighten the 4 set screws.