Installation guidelines, Rw atlas – Waterworks R.W. Atlas Exposed Thermostatic Valve with Metal Lever Handles User Manual

Page 2

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

RW ATLAS

Exposed Thermostatic Valve

INSTALLATION GUIDELINES

Page 2 of 4

8.10.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

RW ATLAS EXPOSED THERMOSTATIC VALVE WITH METAL WHEEL HANDLE (STYLE# RWXS01)

& METAL LEVER HANDLE (STYLE # RWXS10)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

ROUGH IN:

¾ See Figure - 01 for Steps 1-4.

1.

Run well supported 3/4" hot and cold copper supply

lines for maximum flow.

2. Determine the ideal location of the valve, based on

user preferences. Install blocking to properly secure

the valve body.

3. Verify the supplies and outlet are secure and level.

The inlets must have a spread of 11-1/2"MIN to 11-

3/4"MAX. The outlet must be 5-7/8"MIN to 6" MAX

vertically from the inlets and centered horizontally

between the two inlets. Make sure the hot supply is

on the left and the cold supply is on the right. Cap

off supplies and outlet and check for leaks.

4. Cut the copper lines so they extend 15/16" from the

finished wall.

Figure - 01

11

1

2

" MIN - 11

3

4

" MAX

5

7

8

" MIN - 6" MAX

15

16

" FROM

FINISHED WALL

OU

TL

ET

CO

LD

SU

PP

LY

HO

T

SU

PP

LY

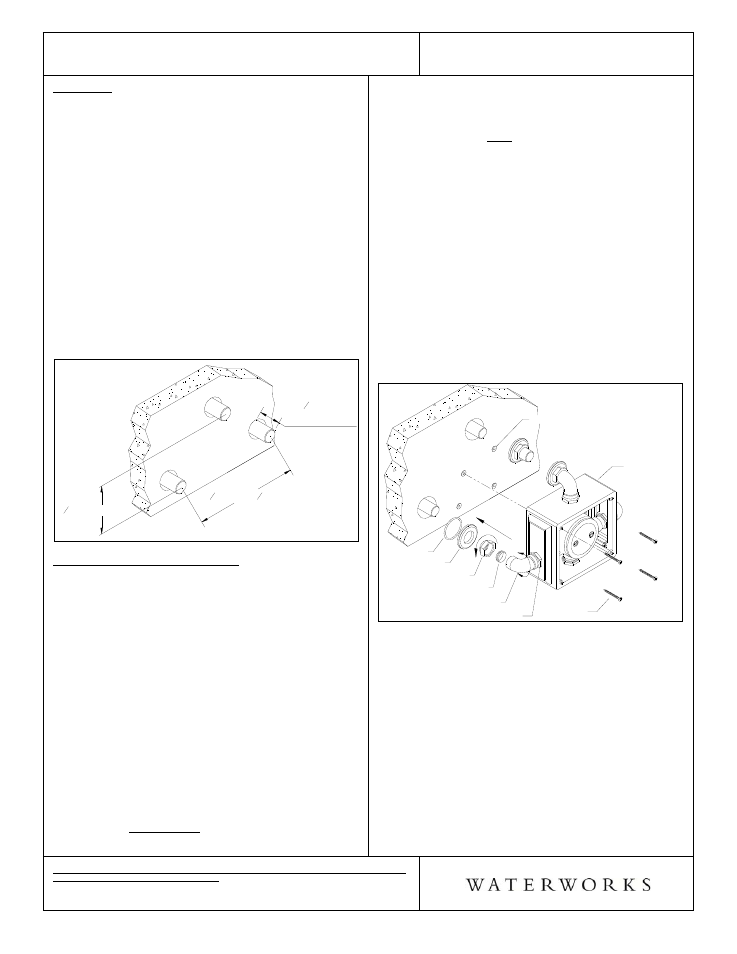

EXPOSED VALVE INSTALLATION:

¾ See Figure - 02 for Steps 5-13.

5. Unthread and remove the compression nuts and

compression rings, along with escutcheons and o-

rings from each elbow.

6. Slide the o-ring, escutcheon, compression nut and

compression ring over each connection tube,

making sure the threading on the compression nut is

facing outwards.

7. Loosen the knurled collars and thread the elbows

into the valve body until they stop, then un-thread

enough so that they align with the supply tubes and

outlet tube (MAXIMUM 3 ROTATIONS). Note that

the elbow seal is created by internal o-rings and

NOT by fully tightening the elbow.

8. Position the valve body assembly onto the supplies

and outlet until they are fully seated into the elbow

and then hand tighten the compression nuts. Slide

the escutcheon back towards the wall; and if the gap

is too large, as to where the escutcheon slides off

the compression nut, cut the supply and outlet tubes

accordingly.

9. With the valve level and up against the wall, mark

the 4 mounting hole locations through the holes that

are on the back plate of the valve body.

10. Loosen the compression nuts and remove the valve

body.

11. Drill the wall for the 4 wall anchors provided and

install them.

12. Re-install the valve onto the supply and outlet tubes,

then , using a wrench, tighten the compression nuts

fully. Tighten the knurled collars so that they are

tight against the side of the valve body. Make sure

the escutcheons are against the wall, with the o-ring

behind it.

13. Install the screws, through the valve body and into

the wall anchors to fully secure the assembly.

Figure - 02

SCREW

KNURLED COLLAR

ELBOW

COMPRESSION RING

COMPRESSION NUT

ESCUTCHEON

O-RING

WALL ANCHOR

VALVE BODY