Waterworks Regulator Gooseneck Double Spout Marquee Kitchen Faucet, Metal Wheel Handles and Spray User Manual

Installation guidelines

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

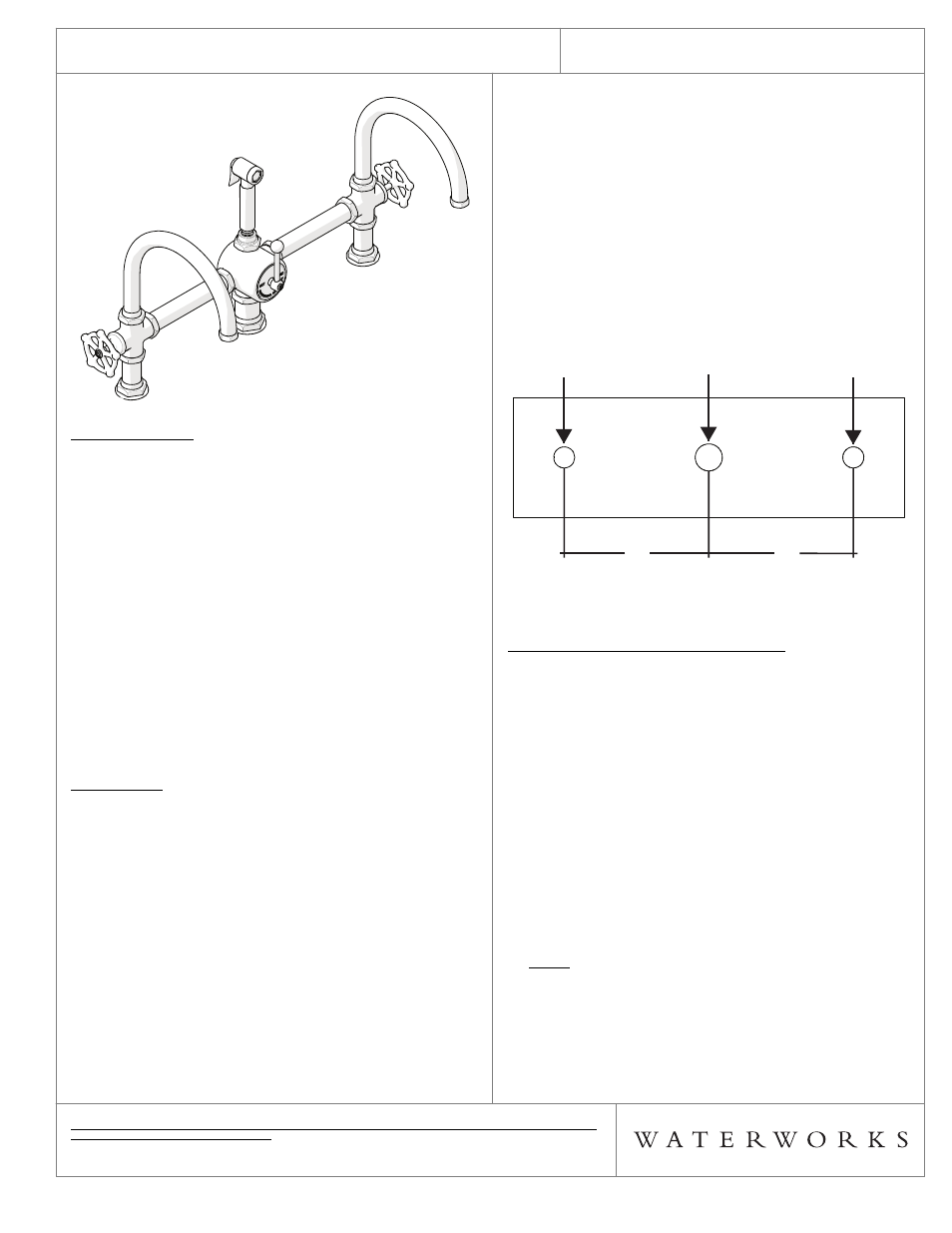

REGULATOR

Gooseneck Double Spout Marquee Kitchen Faucet

Installation Guidelines

Page 1 of 5

Rev - 01

10.9.2014

These guidelines have been prepared for the professional contractor to aid in the installation of:

REGULATOR GOOSENECK DOUBLE SPOUT MARQUEE KITCHEN FAUCET WITH METAL WHEEL HANDLES AND

SPRAY (STYLE No. RGKM50, RG50KM UK)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

STYLE No. RGKM50†

SPECIFICATIONS:

Deck Thickness Maximum: 2” (51mm)

Fittings Hole Diameter [Center]: Ø2-1/4” (57mm)

Fittings Hole Diameter [Left, Right]: Ø1-3/4” (44mm)

Handle Turn Angle: Quarter Turn

Inlet Connection Size: 3/8”

Inlet Connection Type: Compression Connection Hoses†

Integrated Diverter: Yes

Restricted Maximum Flow Rate: 2.2gpm (8.3liters/min) ‡

Spout Reach: 10” (254mm)

Spout Swivel: Yes

Spray Hose Length: 79”

Water Pressure Minimum: 30 psi (2.1 Bar)

Water Pressure Maximum: 80 psi (5.5 Bar)

Water Pressure Recommended: 45 psi (3 Bar)

† UK Style No.

RG50KM is supplied with 2 BSP adapters,

assembly required.

‡ Each spout and spray is flow regulated at 2.2gpm.

IMPORTANT:

To ensure this product is installed properly, you must

read and follow these guidelines. The owner/user of

this product must keep this information for future

reference.

This product must be installed by a professional

licensed contractor.

Be sure your installation conforms to all federal, state,

and local codes. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

Inspect the product to ensure you have all the parts

required for proper installation.

Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

DO NOT use putty. Putty contains oil and can cause

permanent discoloration on certain materials such as

marble, granite and any porous surface.

Refer to the specification and assembly drawings

attached. Product is sold partially assembled but

shown fully disassembled for illustrative and service

purposes only.

This product requires 3 holes on the mounting

surface. The center hole must be 2-1/4” [57mm] in

diameter. The left and right holes must be 1-3/4”

[44mm] in diameter, each hole with a 12” [305mm]

on-center spread from the center hole as shown in

Figure – 01. The 12” [305mm] spread can be adjusted

by cutting the TUBES.

FIGURE – 01

TEMPERATURE VALVE INSTALLATION:

The Temperature Valve only mixes hot and cold

water. It does not have a volume/on/off function.

1. Remove the TEE and CHECK VALVE HOUSINGS from

the HOSES on the TEMPERATURE VALVE BODY. See

FIGURE – 02.

2. Remove the NUT, METAL WASHER, and RUBBER

WASHER from the SHANK on the TEMPERATURE

VALVE BODY. Do

NOT remove the O-RING beneath

the ESCUTCHEON. See FIGURE - 02.

3. Ensure that the HOSES are securely tightened to the

TEMPERATURE VALVE BODY, then insert the SHANK

through the Ø2-1/4” [57mm] or center hole on the

mounting surface making sure the O-RING is beneath

the ESCUTCHEON.

NOTE: The HOSES are marked with colored ZIP TIES

to identify their function.

Red for incoming hot supply

water,

blue for incoming cold supply water and green

for outgoing mixed water. See FIGURE – 02.

4. Re-install the RUBBER WASHER, METAL WASHER

and NUT onto the SHANK and securely tighten the

NUT to secure the TEMPERATURE VALVE BODY to

the mounting surface.

12"

[305mm]

ADJUSTABLE

12"

[305mm]

ADJUSTABLE

Ø2-1/4"

[57mm]

Ø1-3/4"

[44mm]

Ø1-3/4"

[44mm]