Waterworks R.W. Atlas Exposed Thermostatic Valve with Metal Lever Handles User Manual

Installation guidelines

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

RW ATLAS

Exposed Thermostatic Valve

INSTALLATION GUIDELINES

Page 1 of 4

8.10.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

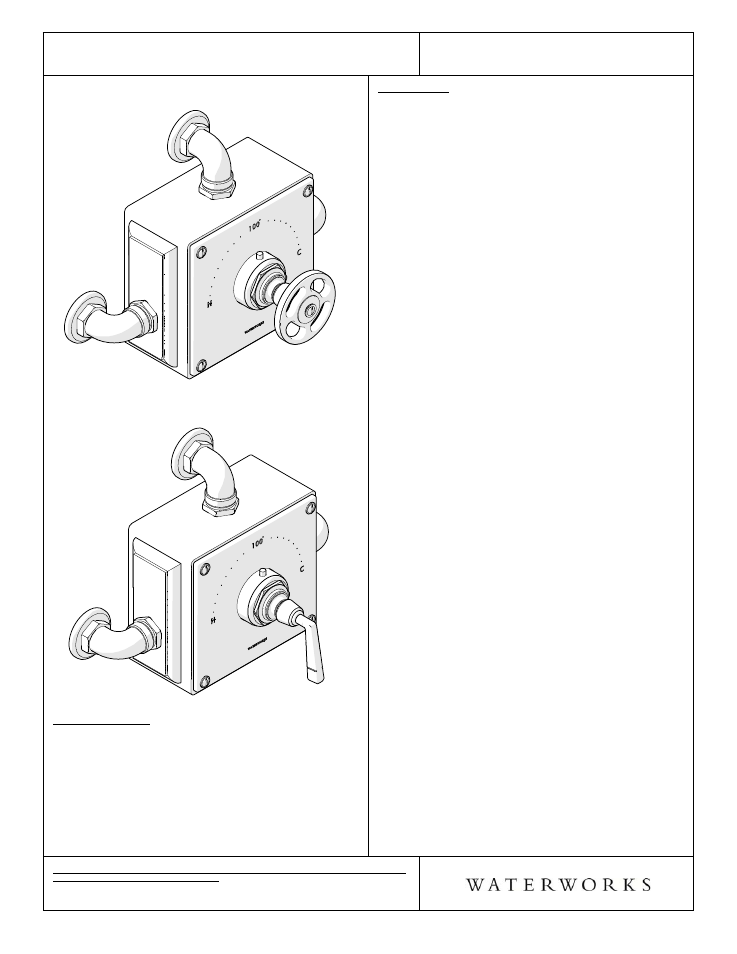

RW ATLAS EXPOSED THERMOSTATIC VALVE WITH METAL WHEEL HANDLE (STYLE# RWXS01)

& METAL LEVER HANDLE (STYLE # RWXS10)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

Metal Wheel Handle

Style No. RWXS01

Metal Lever Handle

Style No. RWXS10

SPECIFICATIONS:

Connection Type:

3

/

4

" Copper Compression

Inlet Spread: 11

1

/

2

" MIN - 11

3

/

4

" MAX

Outlet Spread (From Inlets): 5

7

/

8

" MIN - 6" MAX

Recommended Pressure: 45 psi

IMPORTANT:

¾ To ensure this product is installed properly, you

must read and follow these guidelines.

¾ The owner/user of this product must keep this

information for future reference.

¾ This product is supplied with the Waterworks

Universal Thermostatic Valve (STYLE # GUTH37)

which features anti-scald protection. The risk of

scalding exists until the installer has properly

calibrated/adjusted the temperature setting during

final trim installation. Refer to the Installation

Guidelines of the thermostatic valve for additional

information.

¾ Be sure your installation conforms to federal state,

and local codes. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

¾ This exposed thermostatic valve only mixes hot and

cold water. It does not have volume control or shut-

off capabilities. A diverter or wall valve (sold

separately) control on/off/volume and must be

installed for each fitting that will have water flowing

to it. This valve cannot be used directly with a

diverting tub spout.

¾ This product must be installed by a professional

licensed contractor and must be onsite prior to

rough-in, this allows the installer to visualize the

installation.

¾ Proper blocking in the wall is required.

¾ Inspect this product to ensure you have all the parts

required for proper installation.

¾ Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

¾ Install accessible hot and cold service stop valves to

facilitate servicing.

¾ DO NOT use putty on fittings.