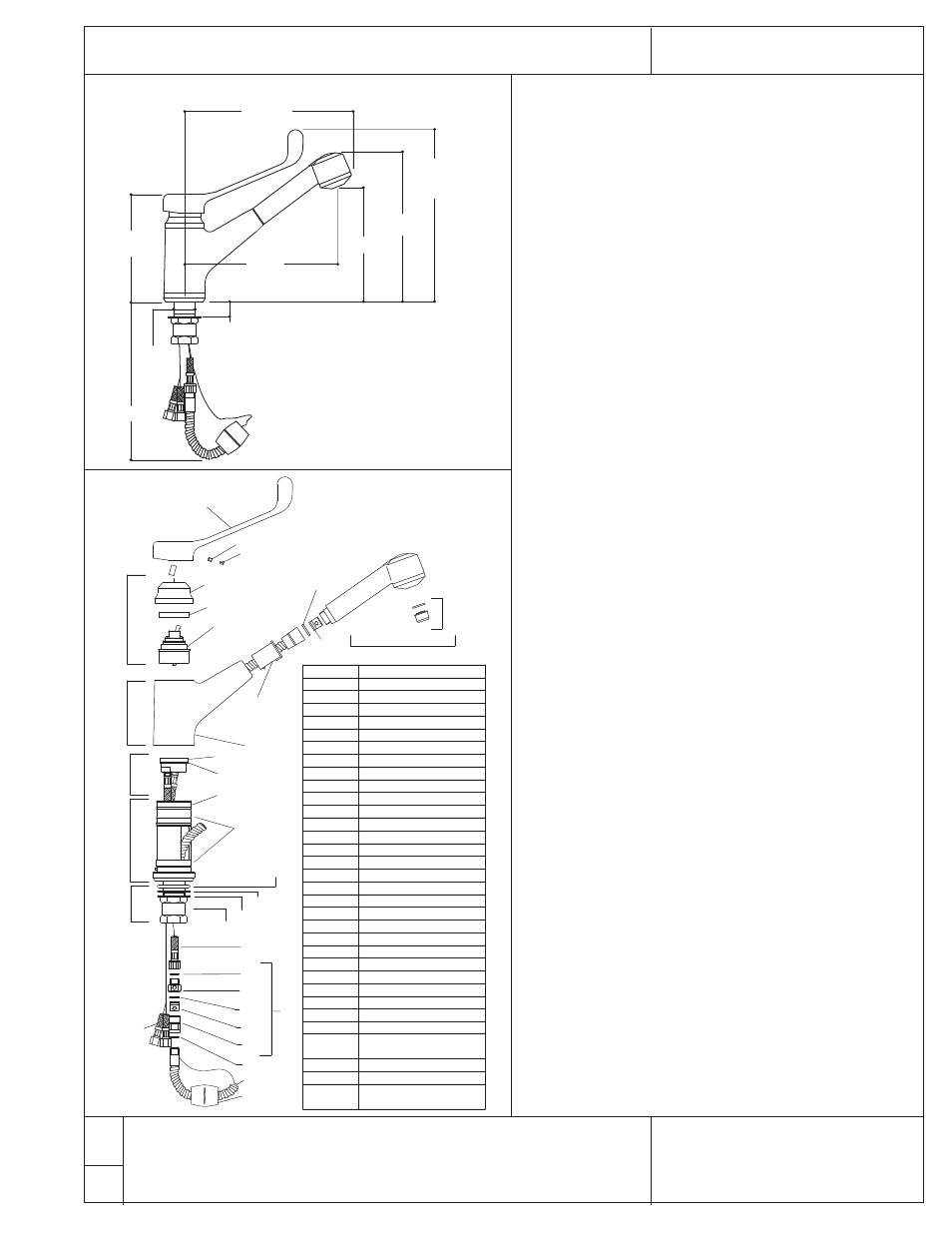

Waterworks Odeon One Hole Low Profile Kitchen Faucet, Metal Lever Handles User Manual

Installation guidelines

Odeon

®

Kitchen Mixer with Pullout Sprayer

10/03

W A T E R W O R K S

®

These guidelines have been prepared for the professional contractor to aid in the installation of:

ODEON

®

KITCHEN MIXER WITH PULLOUT SPRAYER

(WWKM13)

All dimensions are based on original specifications and are subject to change and variation.

Please consult your Design Associate for current specifications.

Installation Guidelines

1

INSTALLATION GUIDELINES

These guidelines have been prepared for the professional contractor to

aid in installation. IIm

mp

poorrtta

an

ntt n

noottee:: This faucet is protected against back flow by a

certified double check valve system. One check valve is located at the inlet of the

sprayhead hose and one is located at the inlet of the sprayhead. These check valves

should not be removed.

➢ Use only a protected, smooth-jawed or strap wrench on any finished

surface.

➢ If possible, install the faucet assembly on the sink or mounting surface

before setting.

➢ Remove the barrel nut(7D), metal washer (7C) and rubber washer (7B)

from the base of the spout.

➢ Insert the supply hoses (4D) and spout shank through the mounting hole

on the sink. Secure the faucet body (6) using the barrel nut (7D) and

washers (7C+7B) provided (the barrel nut should only be hand-tightened

at this time). Do not use plumber's putty, upper and lower washers are

provided.The barrel nut (7D) will accommodate various deck thicknesses.

For standard thickness(1" or less), apply the barrel nut (7D) with the

unthreaded portion first.

➢ Check the spouts rotation to ensure that it rotates to the left and the right.

Now the barrel nut (7D) can be fully tightened.

➢ Feed the male threaded end of the spray hose (5B) into the faucet body

(3) until the sprayer (9) is fully seated.

➢ Connect the male threaded end of the spray hose (5B) to the check valve

assembly (10).Then connect the outlet hose (4C) to the other side of the

check valve assembly (10). Be sure to use the washers provided.

➢ Attach the weight (5C) to the hose (5B) on the spout side of the loop just

above the bend using the screws provided.

➢ Connect the supply hoses (4D) to the water supply valves (not supplied).

➢ Check that all connections are watertight.

➢ After installation, unscrew and remove the pullout sprayer (9) from the

spray hose (5B). With the spray hose (5B) in hand and positioned over the

sink move the faucet lever (1) to the full open position to flush out any

debris in the supply lines. Once the lines have been flushed, turn the faucet

off and reinstall the sprayer.

➢ If further assistance is required, please contact Product Support at:

1-800-927-2120 (8am-7pm EST).

OPERATION:

➢ Lift the handle (1) to operate the faucet. Raising the handle upward

increases the volume.

➢ Rotate to the left for hot water and to the right for cold water.

➢ Pressing the button on the top of the sprayer (9) changes the flow.The

normal flow is aerated and pressing the button changes it to a fine spray.

Once the faucet is turned off the sprayer reverts back to the normal flow.

WWKM13

16"

6

1

/

2

"

1

5

/

8

"

max

1

5

/

16

"

9

1

/

2

"

6

3

/

4

"

8

3

/

4

"

12

3

/

4

" (open)

10

7

/

8

" (closed)

10

1

/

2

"

Notes:

• Drill hole size: 1

3

/

8

"

• Flexible supply hose

connections:

3

/

8

" o.d.

compression

DOC. PRT.

DESCRIPTION

1

Lever

1A

Screw

1B

Button

2A

Cap

2B

Nut

2C

Cartridge

3

Body

3A

Plastic insert

4

Insert assy

4A

Insert

4C

Outlet hose

4D

Supply hose

5A

Rubber Washer

5B

Spray hose

5C

Weight

5D

Rubber washer

6

Inner body assy

6A

Inner body

6B

O'ring

7

Mounting nut assy

7A

O'ring

7B

Rubber washer

7C

Metal washer

7D

Barrel nut

8

Flow r. w/check v.

9

Pull out spray

9A

Aerator set

4

6

7

9

9A

5D

1A

1B

2

3

7D

7C

7B

7A

6B

6A

4B

4A

3B

5B

4D

4C

3A

2A

2B

2C

1

Rubber washer

Check valve housing

Rubber washer

10A

Check valve

10B

Check valve housing

10C

10D

10E

(upper)

(lower)

5C

5A

10

8

10A

10B

10C

10D

10E