Carrier 17EX User Manual

Page 90

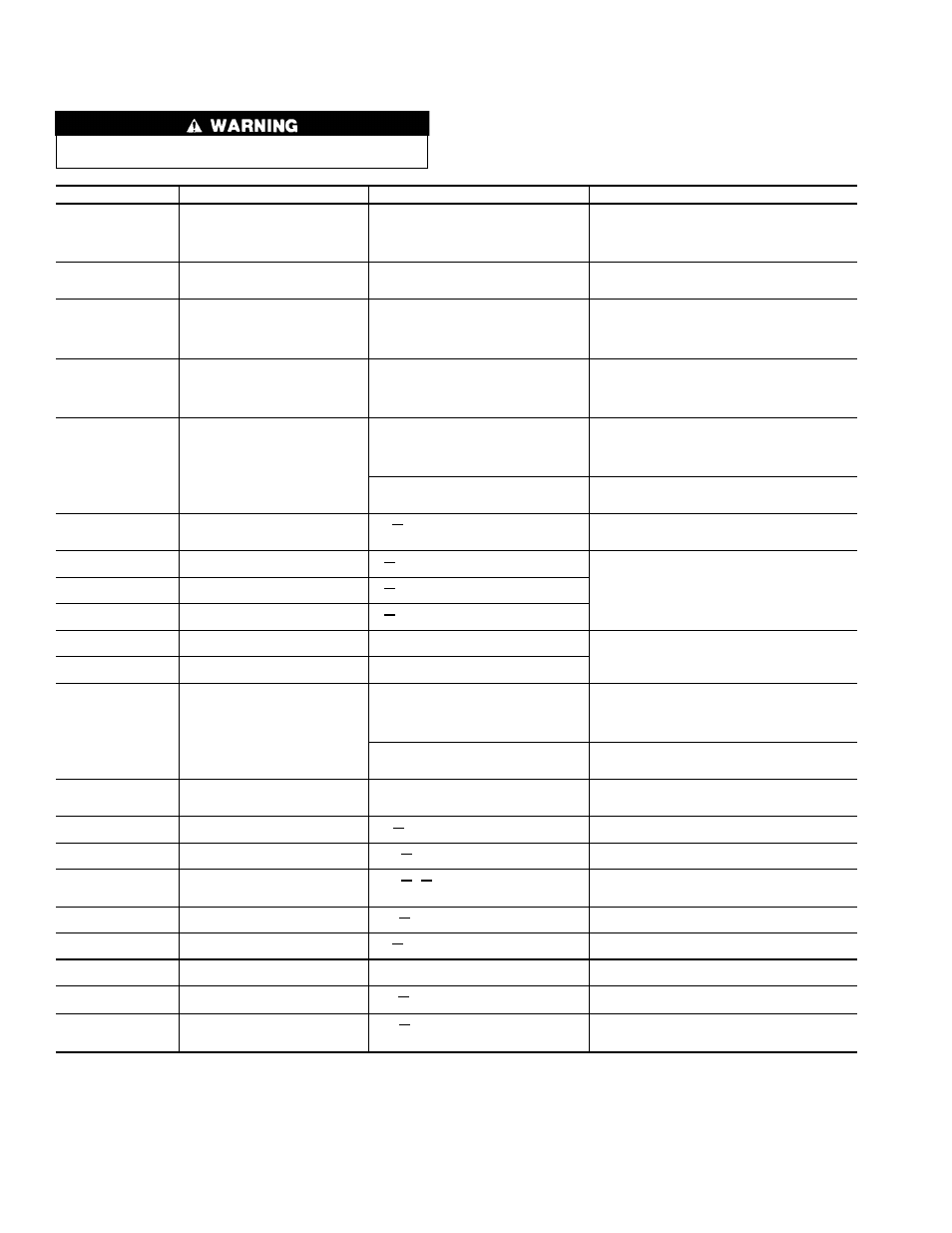

Table 12 — LID Primary and Secondary Messages and Custom Alarm/Alert Messages

with Troubleshooting Guides (cont)

L. CHILLER PROTECT LIMIT FAULTS

Excessive numbers of the same fault can lead to severe chiller

damage. Seek service expertise.

PRIMARY MESSAGE

SECONDARY MESSAGE

ALARM MESSAGE/PRIMARY CAUSE

ADDITIONAL CAUSE/REMEDY

PROTECTIVE LIMIT

HIGH DISCHARGE TEMP

CMPD [VALUE] exceeded limit of [LIMIT]*.

Check discharge temperature.

Check discharge temperature immediately. Check sen-

sor for accuracy; check for proper condenser flow and

temperature; check oil reservoir temperature. Check

condenser for fouled tubes or air in chiller. Check for

proper guide vane actuator operation.

PROTECTIVE LIMIT

LOW REFRIGERANT TEMP

ERT [VALUE] exceeded limit of [LIMIT]*.

Check evap pump and flow switch.

Check for proper amount of refrigerant charge; check

for proper water flow and temperatures. Check for

proper guide vane actuator operation.

PROTECTIVE LIMIT

HIGH MOTOR TEMPERATURE

MTRW [VALUE] exceeded limit of [LIMIT]*.

Check motor cooling and solenoid.

Check motor temperature immediately. Check sen-

sor for accuracy. Check for proper condenser flow and

temperature. Check motor cooling system for restric-

tions. Check motor cooling solenoid for proper opera-

tion. Check refrigerant filter.

PROTECTIVE LIMIT

HIGH BEARING TEMPERATURE

MTRB [VALUE] exceeded limit of [LIMIT]*.

Check oil cooling control.

Check for throttled oil supply isolation valves. Valves

should be wide open. Check oil cooler thermal ex-

pansion valve. Check sensor accuracy. Check jour-

nal and thrust bearings. Check refrigerant filter. Check

for excessive oil sump level.

PROTECTIVE LIMIT

LOW OIL PRESSURE

OILPD [VALUE] exceeded limit of [LIMIT]*.

Check oil pump and transducer.

Check power to oil pump and oil level. Check for dirty

filters or oil foaming at start-up. Check for thermal over-

load cutout. Reduce ramp load rate if foaming noted.

NOTE: This alarm is not related to pressure switch

problems.

Low Oil Pressure [OPEN]*. Check oil

pressure switch/pump and 2C aux.

Check the oil pressure switch for proper operation.

Check oil pump for proper pressure. Check for ex-

cessive refrigerant in oil system.

PROTECTIVE LIMIT

NO MOTOR CURRENT

CA

P Loss of Motor Current: Check

sensor.

Check wiring: Check torque setting on solid-state starter.

Check for main circuit breaker trip. Check power sup-

ply to PSIO module.

PROTECTIVE LIMIT

POWER LOSS

V

P Power Loss: Check voltage

supply.

Check 24-vac input on the SMM (terminals 23 and

24). Check transformers to SMM. Check power to PSIO

module. Check distribution bus. Consult power

company.

PROTECTIVE LIMIT

LOW LINE VOLTAGE

V

P [VALUE] exceeded limit of [LIMIT]*.

Check voltage supply.

PROTECTIVE LIMIT

HIGH LINE VOLTAGE

V

P [VALUE] exceeded limit of [LIMIT]*.

Check voltage supply.

PROTECTIVE LIMIT

LOW CHILLED WATER FLOW

EVFL Flow Fault: Check evap pump/flow

switch.

Perform pumps control test (from CONTROL TEST

table) and verify proper switch operation. Check all

water valves and pump operation.

PROTECTIVE LIMIT

LOW CONDENSER WATER FLOW

CDFL Flow Fault: Check condenser pump/

flow switch.

PROTECTIVE LIMIT

HIGH CONDENSER PRESSURE

High Cond Pressure [OPEN]*: Check switch,

oil pressure contact, and water temp/flow.

Check the high-pressure switch. Check for proper con-

denser pressures and condenser water flow. Check

for fouled tubes. Check the 2C aux. contact and the

oil pressure switch in the power panel. This alarm is

not caused by the transducer.

High Cond Pressure [VALUE]*: Check switch,

water flow, and transducer.

Check water flow in condenser. Check for fouled tubes.

Transducer should be checked for accuracy. This alarm

is not caused by the high pressure switch.

PROTECTIVE LIMIT

HIGH CONDENSER PRESSURE

High Cond Pressure [VALUE]*: Check switch,

water flow, and transducer.

Check water flow in condenser. Check for fouled tubes.

Transducer should be checked for accuracy. This alarm

is not caused by the high pressure switch.

PROTECTIVE LIMIT

1CR AUX CONTACT FAULT

CR

AUX Starter Contact Fault: Check

1CR/1M aux contacts.

1CR auxiliary contact opened while chiller was run-

ning. Check starter for proper operation.

PROTECTIVE LIMIT

RUN AUX CONTACT FAULT

RUN

AUX Starter Contact Fault: Check

1CR/1M aux contacts.

Run auxiliary contact opened while chiller was run-

ning. Check starter for proper operation.

PROTECTIVE LIMIT

CCN OVERRIDE STOP

CHIL

S

S CCN Override Stop while in

LOCAL run mode.

CCN has signaled chiller to stop. Reset and restart

when ready. If the signal was sent by the LID, release

the Stop signal on STATUS01 table.

PROTECTIVE LIMIT

SPARE SAFETY DEVICE

SRP

PL Spare Safety Fault: Check

contacts.

Spare safety input has tripped or factory-installed jumper

not present.

PROTECTIVE LIMIT

EXCESSIVE MOTOR AMPS

CA

P [VALUE] exceeded limit of [LIMIT]*.

High Amps; Check guide vane drive.

Check motor current for proper calibration. Check guide

vane drive and actuator for proper operation.

PROTECTIVE LIMIT

EXCESSIVE COMPR SURGE

Compressor Surge: Check condenser wa-

ter temp and flow.

Check condenser flow and temperatures. Check con-

figuration of surge protection.

PROTECTIVE LIMIT

STARTER FAULT

STR

FLT Starter Fault: Check starter for

fault source.

Check starter for possible ground fault, reverse rota-

tion, voltage trip, etc.

PROTECTIVE LIMIT

STARTER OVERLOAD TRIP

STR

FLT Starter Overload Trip: Check

amps calibration/reset overload.

Reset overloads and reset alarm. Check motor cur-

rent calibration or overload calibration (do not field-

calibrate overloads).

*[LIMIT] is shown on the LID as the temperature, pressure, voltage, etc., set point predefined or selected by the

operator as an override, alert, or alarm condition. [VALUE] is the actual temperature, pressure, voltage, etc., at

which the control tripped. [OPEN] indicates that an input circuit is open.

90