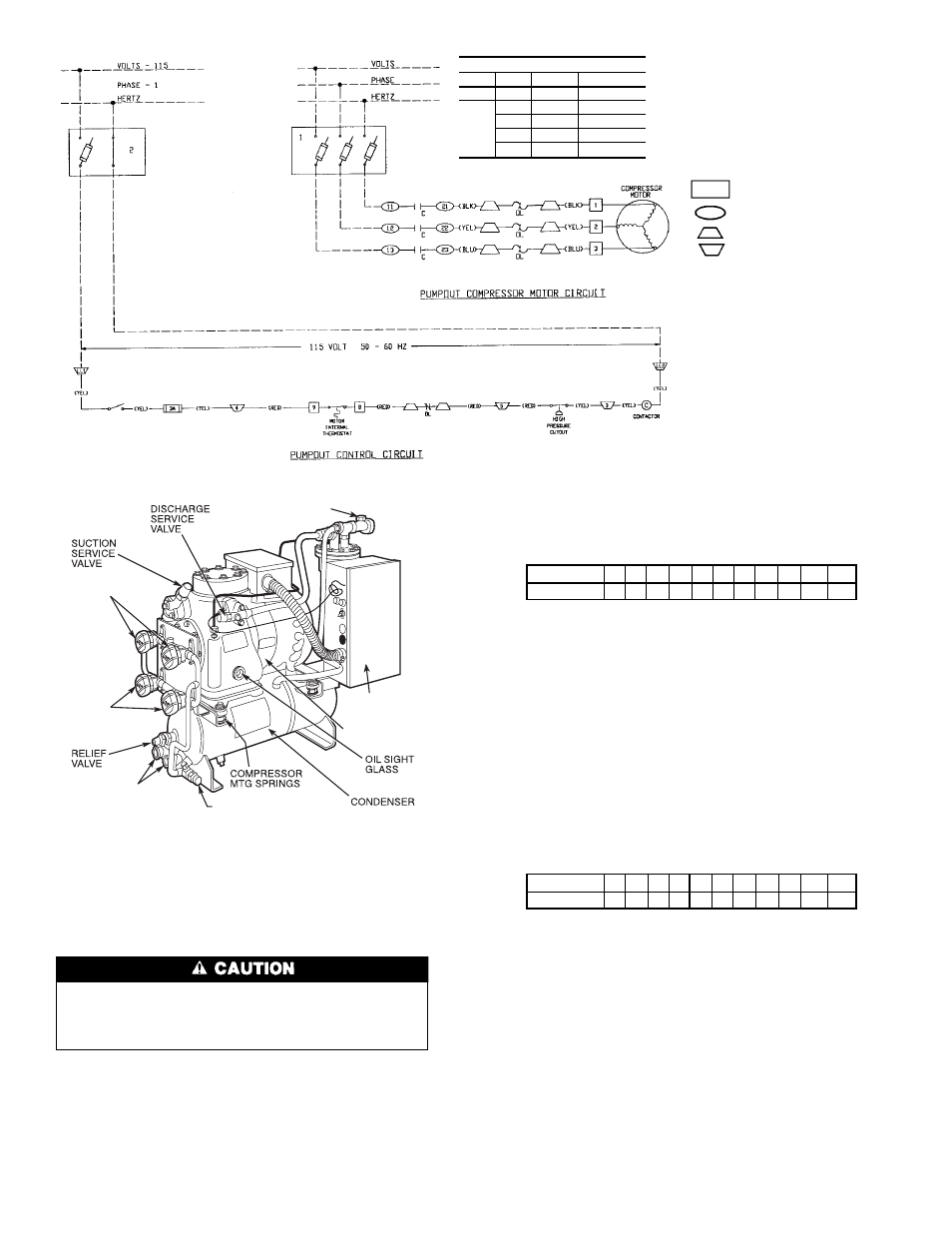

Fig. 34 — optional pumpout compressor 66 – Carrier 17EX User Manual

Page 66

2. To determine economizer/storage vessel pressure, attach

a 30 in.-0-400 psi (-101-0-2760 kPa) gage to the vessel.

3. Refer to Fig. 32 for valve locations and numbers.

Transfer, addition, or removal of refrigerant in spring-

isolated chillers may place severe stress on external pip-

ing if springs have not been blocked in both up and down

directions.

Transferring Refrigerant into the Economizer/

Storage Vessel —

These steps describe the method of

moving refrigerant from the cooler/condenser/compressor sec-

tions into the economizer/storage vessel. This is normally

done to prepare for service work on the cooler, condenser, or

the compressor components or for long-term chiller

shutdown.

1. Isolate and push refrigerant into the economizer/storage

vessel with the pumpout compressor.

a. Valve positions: (Blank spaces indicate open valves).

VALVE

1

2

3

4

5

6

7

8

9

10

11

CONDITION

C

C

C

C

C

C

b. Turn off the chiller water pumps and pumpout con-

denser water.

c. Turn on pumpout compressor to push liquid out of the

cooler/condenser/compressor section.

d. When all liquid has been pushed into the economizer/

storage vessel, close the cooler isolation valve 7.

e. Access the CONTROL TEST table on the LID. Select

the PUMPDOWN/LOCKOUT screen. From this screen,

turn on the chiller water pumps and view the chiller

pressures.

f. Turn off pumpout compressor.

2. Evacuate refrigerant gas from the cooler/condenser/

compressor vessel.

a. Valve positions: close valves 2 and 5, open valves 3

and 4.

VALVE

1

2

3

4

5

6

7

8

9

10

11

CONDITION

C

C

C

C

C

C

C

b. Turn on the pumpout condenser water.

c. Run the pumpout compressor until the suction reaches

15 in. Hg (50 kPa abs). Monitor pressures on the LID

and on the refrigerant gages.

d. Close valve 1.

e. Turn off pumpout compressor.

f. Close valves 3, 4, and 6. (All valves are now closed.)

g. Turn off pumpout condenser water.

h. Use the PUMPDOWN LOCKOUT screen on the LID

to turn off the chiller water pumps and to lock out the

chiller compressor from operation.

Fig. 33 — Pumpout Unit Wiring Schematic

LEGEND

1

— Compressor Motor

Circuit Disconnect

2

— Control Circuit

Disconnect

C

— Contactor

OL

— Compressor Overload

RLA

— Rated Load Amps

T’stat — Internal Thermostat

Compressor Terminal

Contactor Terminal

Overload Terminal

Pumpout Unit Terminal

COMPRESSOR MOTOR

Hz

Ph

Volts

Max. RLA

50

3

400

4.7

60

3

298

10.9

3

230

9.5

3

460

4.7

3

375

3.8

CONDENSER

WATER

CONNECTIONS

(FIELD PIPING)

CONDENSER

DISCHARGE VALVE

VENT VALVE

CONTROL BOX

(WIRING BY

CONTRACTOR)

COMPRESSOR

VALVES

VALVES

Fig. 34 — Optional Pumpout Compressor

66