Carrier 17EX User Manual

Page 23

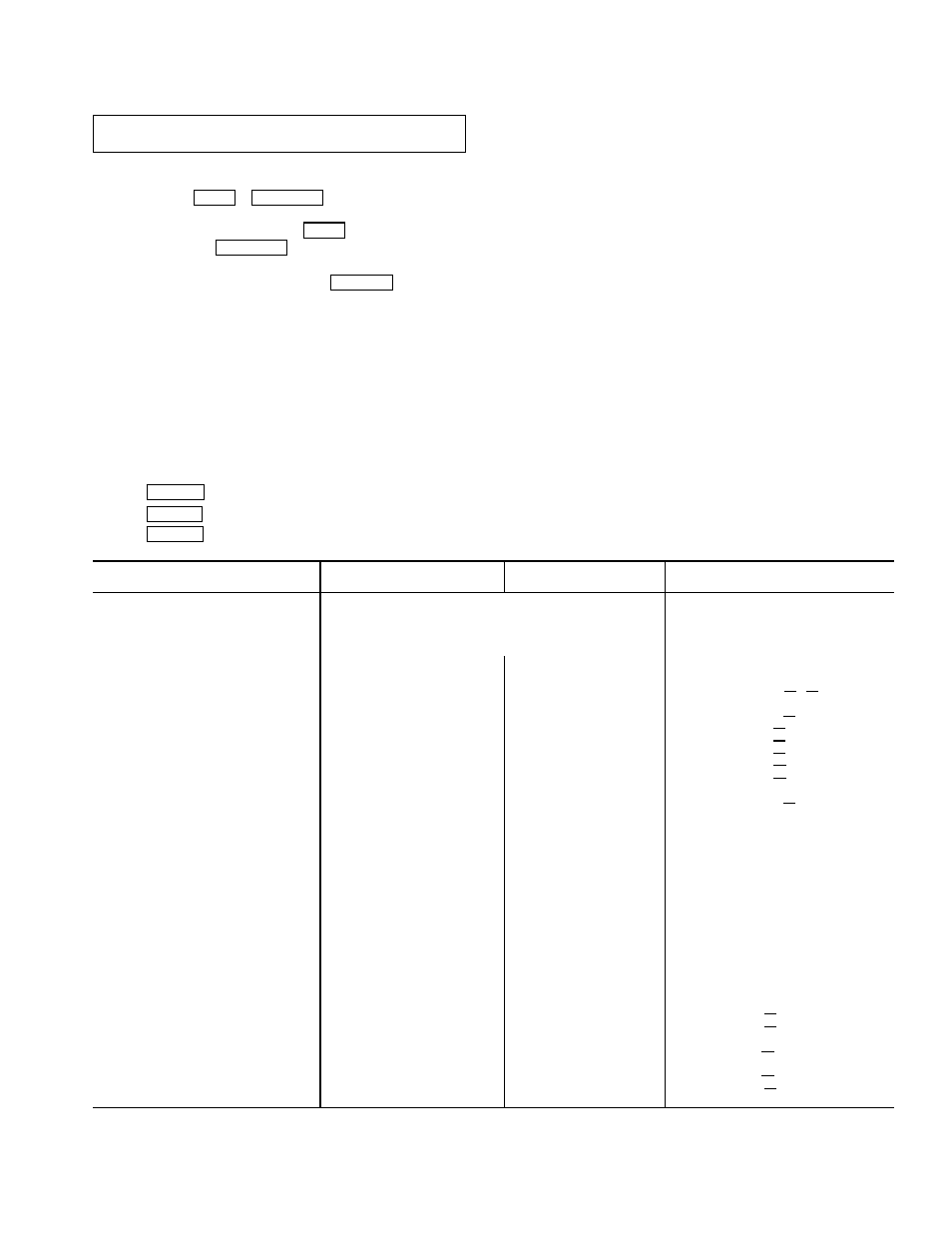

Table 2 — LID Display Data

NOTES:

IMPORTANT: The following notes apply to all Table 2

examples.

1. Only 12 lines of information appear on the LID screen at any one

time. Press the NEXT or PREVIOUS softkey to highlight a point

or to view items below or above the current screen. If you have a

chiller with a backlit LID, press the NEXT softkey twice to page

forward; press the PREVIOUS softkey twice to page back.

2. To access the information shown in Examples 6 through 14, enter

your 4-digit password after pressing the SERVICE softkey. If no

softkeys are pressed for 15 minutes, the LID automatically logs off

(to prevent unrestricted access to PIC controls) and reverts to the

default screen. If this happens, you must reenter your password

to access the tables shown in Examples 6 through 14.

3. Terms in the Description column of these tables are listed as they

appear on the LID screen.

4. The LID may be configured in English or Metric (SI) units using

the LID CONFIGURATION screen. See the Service Operation sec-

tion, page 42, for instructions on making this change.

5. The items in the Reference Point Name column

do not appear on

the LID screen. They are data or variable names used in CCN or

Building Supervisor software. They are listed in these tables as a

convenience to the operator if it is necessary to cross reference

CCN/BS documentation or use CCN/BS programs. For more in-

formation, see the 17EX CCN literature.

6. Reference Point Names shown in these tables in all capital letters

can be read by CCN and Building Supervisor software. Of these

capitalized names, those preceded by an asterisk can also be

changed (that is, written to) by the CCN, Building Supervisor soft-

ware and the LID. Capitalized Reference Point Names preceded

by two asterisks can be changed only from the LID. Reference

Point Names in lower case type can be viewed by CCN or Build-

ing Supervisor software only by viewing the whole table.

7. Alarms and Alerts: An asterisk

in the far right field of a LID status

screen indicates that the chiller is in an alarm state; an exclama-

tion point in the far right field of the LID screen indicates an alert

state. The asterisk (or exclamation point) indicates that the value

on that line has exceeded (or is approaching) a limit. For more

information on alarms and alerts, see the Alarms and Alerts sec-

tion, page 16.

EXAMPLE 1 — STATUS01 DISPLAY SCREEN

To access this display from the LID default screen:

1. Press

MENU

.

2. Press STATUS (STATUS01 will be highlighted).

3. Press SELECT .

DESCRIPTION

RANGE

UNITS

REFERENCE POINT NAME

(ALARM HISTORY)

Control Mode

Reset.Off. Local. CCN

MODE

Run Status

Timeout. Recycle. Startup.

STATUS

Ramping. Running. Demand.

Override. Shutdown. Abnormal.

Pumpdown

Occupied ?

No/Yes

OCC

Alarm State

Normal/Alarm

ALM

*Chiller Start/Stop

Stop/Start

CHIL

S

S

Base Demand Limit

40-100

%

DLM

*Active Demand Limit

40-100

%

DEM

LIM

Compressor Motor Load

0-999

%

CA

L

Current

0-999

%

CA

P

Amps

0-9999

AMPS

CA

A

*Target Guide Vane Pos

0-100

%

GV

TRG

Actual Guide Vane Pos

0-100

%

GV

ACT

Water/Brine: Setpoint

10-120 (–12.2-48.9)

DEG F (DEG C)

SP

*

Control Point

10-120 (–12.2-48.9)

DEG F (DEG C)

LCW

STPT

Entering Chilled Water

–40-245 (–40-118)

DEG F (DEG C)

ECW

Leaving Chilled Water

–40-245 (–40-118)

DEG F (DEG C)

LCW

Entering Condenser Water

–40-245 (–40-118)

DEG F (DEG C)

ECDW

Leaving Condenser Water

–40-245 (–40-118)

DEG F (DEG C)

LCDW

Evaporator Refrig Temp

–40-245 (–40-118)

DEG F (DEG C)

ERT

Evaporator Pressure

–6.7-420 (–46-2896)

PSI (kPa)

ERP

Condenser Refrig Temp

–40-245 (–40-118)

DEG F (DEG C)

CRT

Condenser Pressure

–6.7-420 (–46-2896)

PSI (kPa)

CRP

Discharge Temperature

–40-245 (–40-118)

DEG F (DEG C)

CMPD

Bearing Temperature

–40-245 (–40-118)

DEG F (DEG C)

MTRB

Motor Winding Temp†

–40-245 (–40-118)

DEG F (DEG C)

MTRW

Motor Winding Hi

Temp Cutout

Normal/Alarm

MTRW

Oil Sump Temperature

–40-245 (–40-118)

DEG F (DEG C)

OILT

Oil Pressure Transducer†

–6.7-420 (–46-2896)

PSI (kPa)

OILP

Oil Pressure**

–6.7-420 (–46-2896)

PSID (kPad)

OILPD

Line Voltage:

Percent

0-999

%

V

P

Actual

0-9999

VOLTS

V

A

*Remote Contacts Input

Off/On

REMCON

Total Compressor Starts

0-65535

c

starts

Starts in 12 Hours

0-8

STARTS

Compressor Ontime

0-500000.0

HOURS

c

hrs

*Service Ontime

0-32767

HOURS

S

HRS

*Compressor Motor kW

0-9999

kW

CKW

†Information is applicable to hermetic chillers (19EX) only.

**Oil pressure is read directly from a differential pressure module on 17EX chillers.

NOTE: values preceded by an asterisk (*) can be forced (changed by an operator) from the LID screen

or from another control device (such as a Carrier Comfort Network [CCN] terminal).

23