Capacity override (see table 4), High discharge temperature control, Oil sump temperature control – Carrier 17EX User Manual

Page 35

2. The motor load ramp loading rate is an operator-configured

value that limits the rate at which the compressor motor

current or compressor motor load increases. (LOAD PULL-

DOWN %/MIN on the CONFIG screen).

To select the ramp type, highlight the SELECT RAMP

TYPE parameter on the CONFIG screen and select either

0 (TEMP) or 1 (LOAD). Motor load (1) is the default ramp

loading control type.

Capacity Override (See Table 4) —

Capacity over-

rides can prevent some safety shutdowns caused by exceed-

ing the motor amperage limit, refrigerant low temperature

safety limit, motor high temperature safety limit, and con-

denser high pressure limit. In all of these cases, there are

2 stages of compressor vane control.

1. The guide vanes are kept from opening further, and the

status line on the LID displays the reason for the

override.

2. The guide vanes are closed until the condition decreases

below the first step set point. Then, the vanes are released

to normal capacity control.

Whenever the motor current demand limit set point is reached,

it activates a capacity override, again using the 2-step pro-

cess. Exceeding 110% of the rated load amps for more than

30 seconds initiates a safety shutdown.

The compressor high lift (surge prevention) set point causes

a capacity override as well. When the surge prevention set

point is reached, the PIC normally prevents the guide vanes

from opening. See the Surge Prevention Algorithm section,

page 37. If the chiller is equipped with the hot gas bypass

option, the PIC opens the hot gas bypass valve instead of

holding the guide vanes.

High Discharge Temperature Control —

If the dis-

charge temperature increases above 200 F (93 C), the guide

vanes are proportionally opened to increase gas flow through

the compressor. If the leaving chilled water temperature drops

5° F (2.8° C) below the control point temperature, chiller

enters the RECYCLE mode.

Oil Sump Temperature Control —

The oil sump tem-

perature control is regulated by the PIC which uses the oil

heater relay when the chiller is shut down.

As part of the pre-start checks executed by the controls,

the PIC compares the oil sump temperature to the evapora-

tor refrigerant temperature. If the difference between these 2

temperatures is 50 F (27.8 C) or less, the start-up is delayed

until the oil temperature difference is 50 F (27.8 C) or more.

Once this temperature is confirmed, the start-up continues.

The oil heater relay is energized whenever the chiller com-

pressor is off and the oil sump temperature is less than

150 F (65.6 C) or the oil sump temperature is less than the

cooler refrigerant temperature plus 70° F (39° C). The oil

heater is turned off when the oil sump temperature is either

• more than 160 F (71.1 C)

• or the oil sump temperature is more than 155 F (68.3 C)

and more than the cooler refrigerant temperature plus

75° F (41.6° C).

The oil heater is always off during start-up or when the

compressor is running.

When a power failure to the PSIO module has occurred

for more than 3 hours (i.e., initial start-up), the compressor

guide vane opening is slowed down to prevent excessive oil

foaming that may result from refrigerant migration into the

oil sump during the power failure. The vane opening is slowed

via temperature ramp loading to a value of 2° F (1.1° C) per

minute.

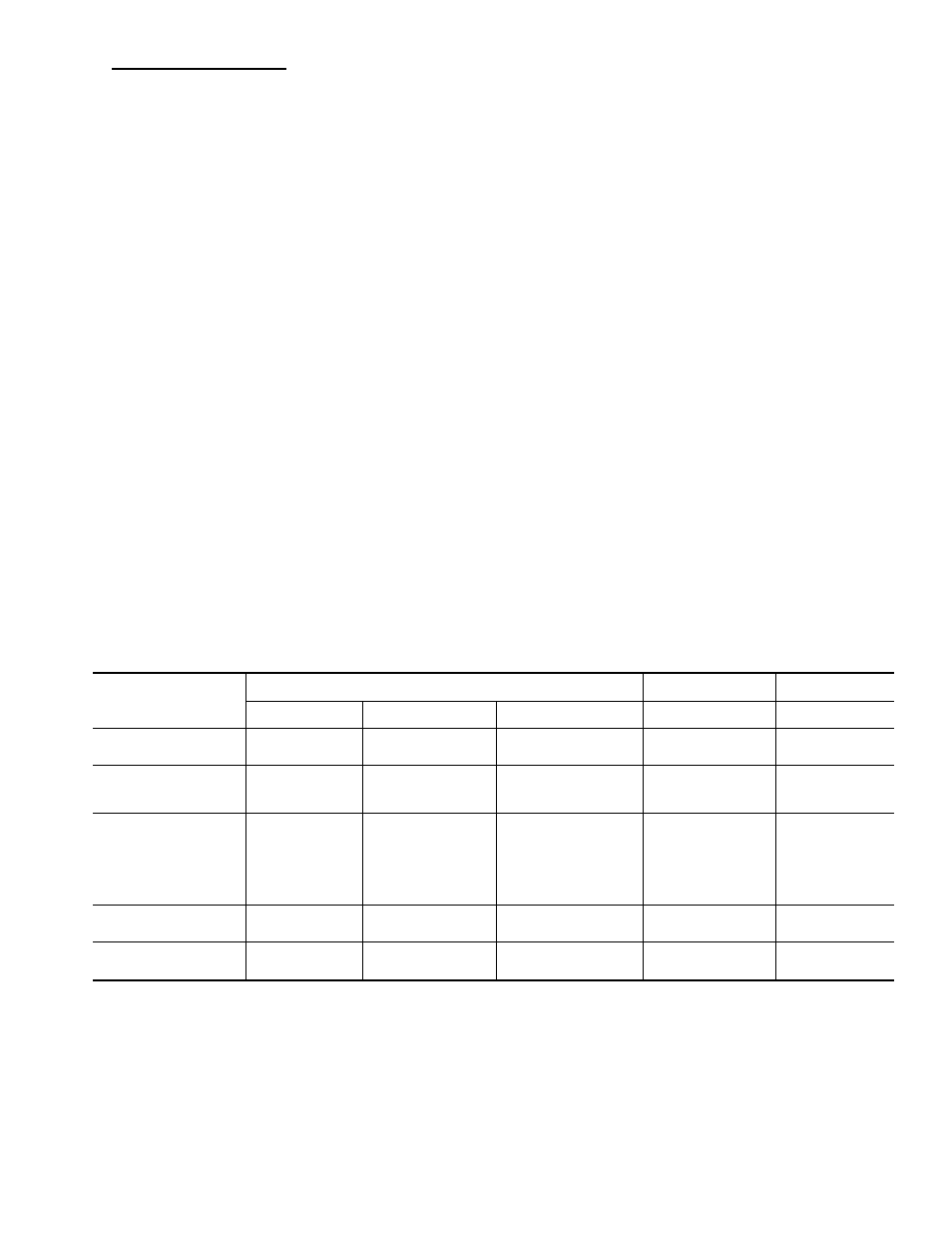

Table 4 — Capacity Overrides

OVERRIDE

CAPACITY

CONTROL

FIRST STAGE SETPOINT

SECOND STAGE

SETPOINT

OVERRIDE

TERMINATION

View/Modify

on LID Screen

Default Value

Configurable Range

Value

Value

HIGH CONDENSER

PRESSURE

Equipment

Service1

125 psig

(862 kPa)

90 to 200 psig

(620 to 1379 kPa)

Ͼ

Override

Set Point

+ 4 psid (28 kPad)

Ͻ

Override

Set Point

LOW REFRIGERANT

TEMPERATURE

(Refrigerant Override

Delta Temperature)

Equipment

Service1

Ͻ

3° F (1.6° C)

(Above Trippoint)

2° to 5° F

(1° to 3° C)

р

Trippoint

+ Override

⌬

T –1° F

(0.56° C)

Ͼ

Trippoint

+ Override

⌬

T +2° F

(1.2° C)

HIGH COMPRESSOR

LIFT

(Surge Prevention)

Equipment

Service1

Min: T1 — 1.5° F

(0.8° C)

P1 — 50 psid

(345 kPad)

Max: T2 — 10° F

(5.6° C)

P2 — 85 psid

(586 kPad)

0.5° to 15° F

(0.3° to 8.3° C)

30 to 170 psid

(207 to1172 kPad)

0.5° to 15° F

(0.3° to 8.3° C)

30 to 170 psid

(207 to 1172 kPad)

None

Within

Lift Limits

Plus Surge/

HGBP

Deadband

Setting

MANUAL

GUIDE VANE

TARGET

Control

Algorithm

Maint01

Automatic

0 to 100%

None

Release of

Manual

Control

MOTOR LOAD —

ACTIVE

DEMAND LIMIT

Status01

100%

40 to 100%

у

5% of

Set Point

2% Lower

Than

Set Point

LEGEND

HGBP — High Gas Bypass

P1

— Minimum Pressure Load

P2

— Maximum Pressure Load

T1

— Minimum Temperature Load

T2

— Maximum Temperature Load

35