Carrier 17EX User Manual

Page 104

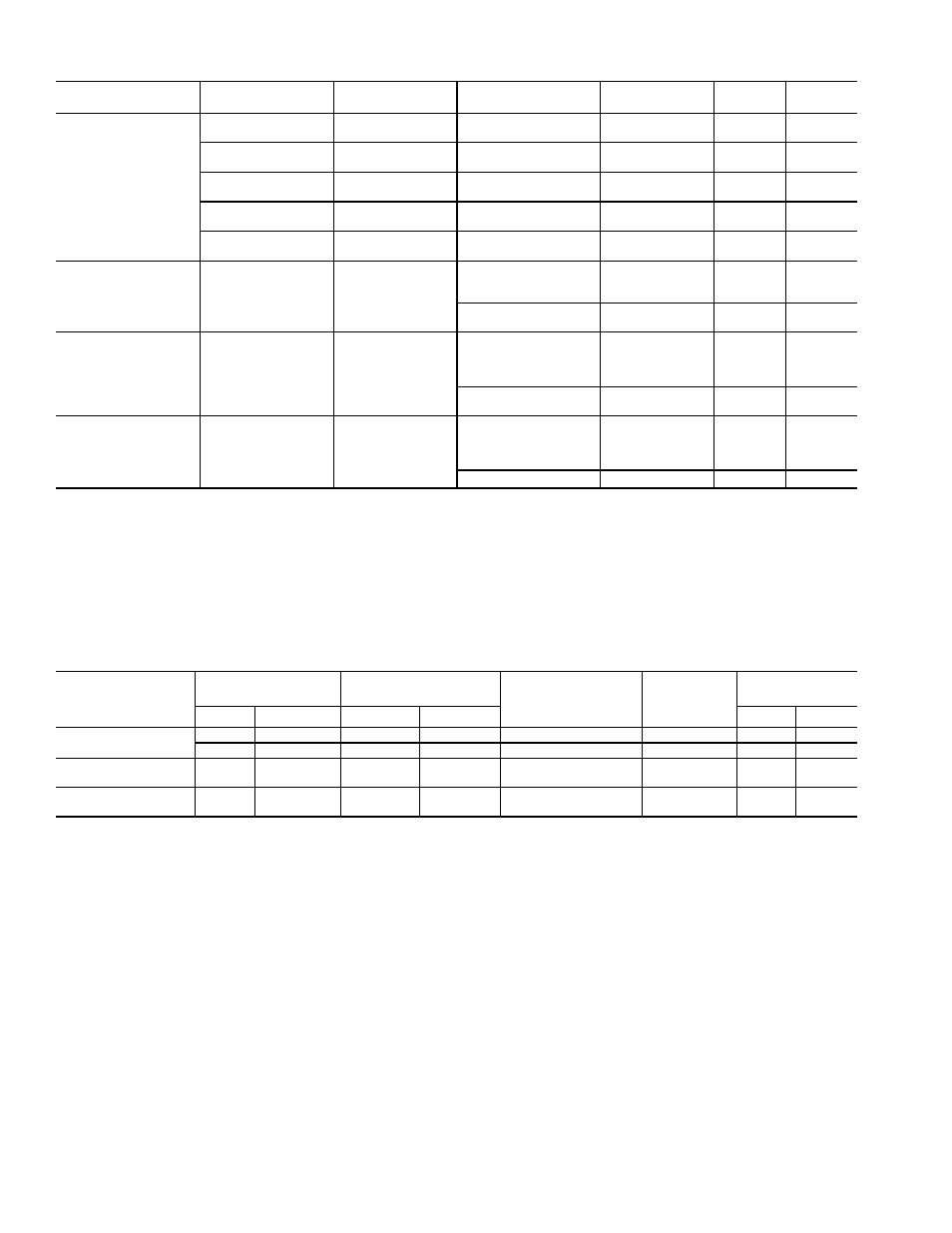

Table 24 — Auxiliary Systems, Electrical Data

POWER SOURCE

ITEM

AVERAGE kW

DESIGN CENTER

VOLTAGE

SUPPLY

V-PH-Hz

FLA

LRA

1

Seal Leakage

Pump

0.23

115

115-1-50/60

4.78

21.7

Motor Space

Heater

0.50

115

115-1-50/60

4.35

4.35

Control Module

and Actuator

0.40

115

115-1-60

3.50

—

115-1-50

Oil Sump Heater

1.00

115

115-1-60

8.70

—

115-1-50

Hot Gas*

Bypass

0.20

115

115-1-50/60

2.00

4.75

2†

Compressor

Oil Pump

0.66

220

200/240-3-60

4.34

24.5

430

380/480-3-60

2.15

13.1

563

507/619-3-60

2.14

25.0

230

220/240-3-50

4.84

28.0

393

346/440-3-50

2.59

12.2

3†

Gear

Oil Pump

0.7

204

200/208-3-60

5.7

33.5

220

208/230-3-60

4.2

30.6

460

440/480-3-60

2.1

15.3

575

518/632-3-60

1.7

12.3

205

190/220-3-50

5.0

28.9

410

380/440-3-50

2.5

14.5

4

Pumpout*

Compressor

3.41

204

200/208-3-60

10.90

63.5

230

220/240-3-60

9.50

57.5

460

440/480-3-60

4.70

28.8

575

550/600-3-60

3.80

23.0

400

380/415-3-50

4.70

28.8

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

*Available as an option on 17EX chillers.

†The compressor and gear oil pump contactors are wired together

on the line side. Their amperage values must be added together

when sizing conductors.

NOTE: The oil pump is powered through a field wiring terminal into

the power panel. Power to the controls and oil heater via the power

panel must be on circuits that can provide continuous service when

the compressor starter is disconnected.

Table 25 — Relief Valve Locations and Data

RELIEF VALVE

LOCATION

HEAT EXCHANGER

SIZE

REQUIRED

C FACTOR

NOMINAL

OUTLET

PIPE SIZE

(in.)

NUMBER OF

VALVES

RATED RELIEF

PRESSURE

Cooler

Condenser

lb air/min.

kg air/sec.

psig

kPa

Cooler

45-47

45-47

216.3

1.64

1

1

⁄

4

FPT

3

225

1551

48

55-57

228.5

1.73

1

1

⁄

4

NPT

3

225

1551

Economizer/Storage

Vessel

ALL

ALL

84.3

0.64

1

1

⁄

4

FPT

2*

225

1551

Pumpout Unit

Condenser

ALL

ALL

1.5

0.01

3

⁄

8

in. Male Flare MPT

1

385

2655

*To ensure relief valve serviceability, and as required in ASHRAE 15,

latest edition, three-way valves and redundant relief valves are in-

stalled on the storage vessel. Only one of the ‘‘No. of Valves’’ listed

are in service at any time.

NOTES:

1. The cooler relief C-factor is for both cooler and condenser vented

through the cooler in accordance with ASHRAE (American

Society of Heating, Refrigeration, and Air Conditioning Engi-

neers) 15, latest edition.

2. Relief valve discharge pipe sizing is to be calculated per latest

version of ASHRAE 15, using the tabulated C-factors and nom-

inal pipe size listed above. Cooler and economizer/storage vessel

rated relief valve pressure is 225 psig (1551 kPa).

3. The pumpout unit condenser contains less than 110 lb (50 kg) of

HFC-134a, which is a Group A1 refrigerant. The ASHRAE 15 stand-

ard exempts small-volume vessels from the requirement to vent

outside. However, Carrier recommends that the pumpout con-

denser be connected to the rest of the vent system.

104