Filling the structural glazing gap, Fig. 109 – EFCO 433 Series User Manual

Page 83

June 2012

PART NO. Y017

Page 83 of 90

Series 433 Triple Set Installation Instructions

SECTION IX: Glazing

(Includes Captured and Structural Glazed Mullion Systems)

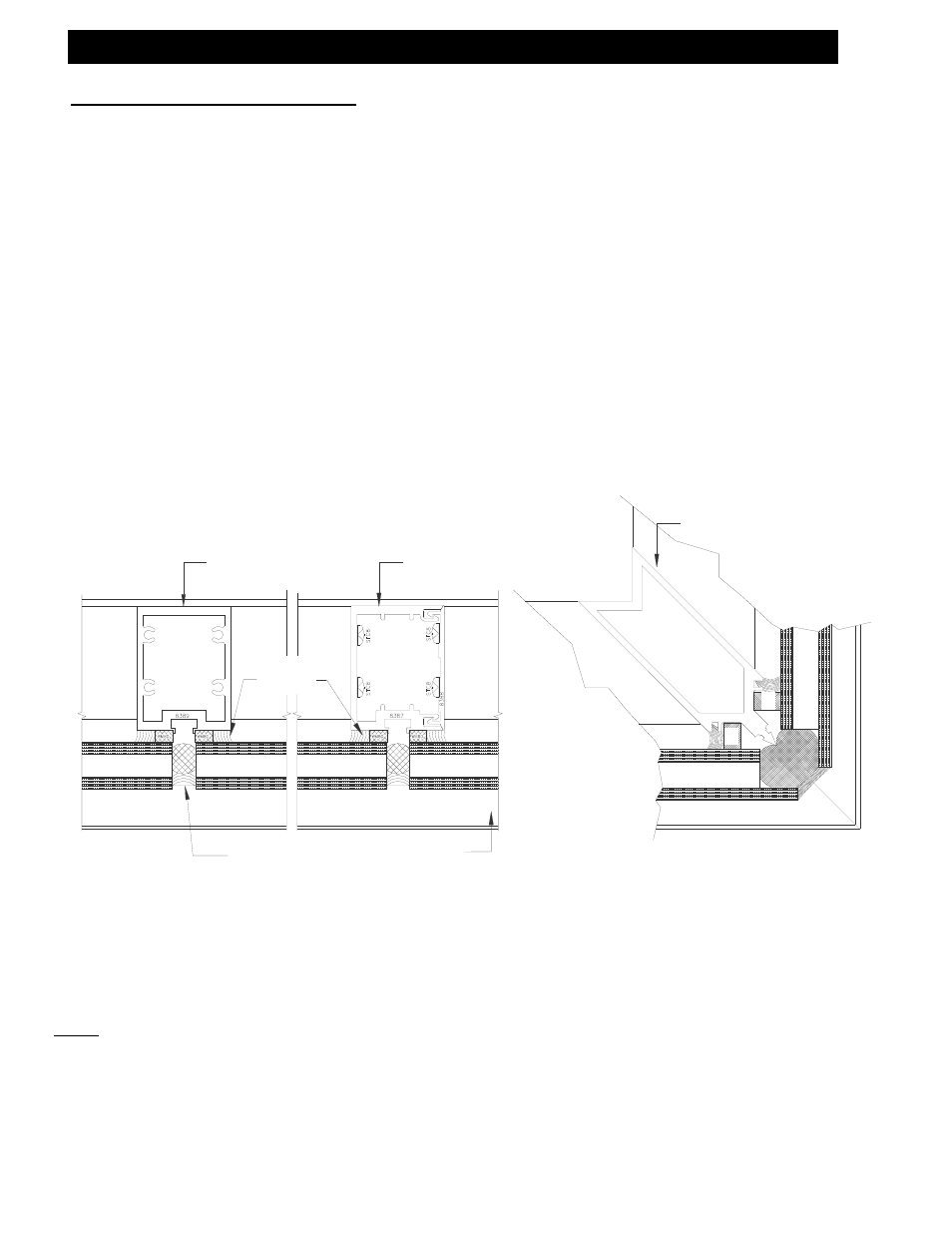

Filling the Structural Glazing Gap

-This procedure applies to the 2-piece structural glazed vertical, the head & sill thru

structural glazed vertical, & the 90 degree structural glaze corner-

After the interior sealant has cured, typically an overnight setup is required, mask off the

glass edges with masking tape to minimize cleanup and provide a professional appearance.

Then remove the temporary glazing clips and proceed with filling the void between the

glass units at the exterior with backer rod and structural silicone sealant for a weather tight

seal. At the horizontal members, fill the cavity with sealant to fill the void out to the gasket.

See Figure 110. Tool the sealant using a putty knife across the glass edges. Remove

excess silicone from the glass surface by removing the masking tape before a skin begins to

form. Any excess sealant on the glass units can be removed with a razor blade.

Note:

The success of structural silicone glazed projects has been the result of compatibility tests

performed on actual materials supplied to the project. The installer must make sure that successful

compatibility tests are performed in accordance with the silicone manufacturer's recommendations

and procedures.

S.S.G. VERTICAL

HEAD & SILL THRU

S.S.G. VERTICAL

VERTICAL THRU

STRUCTURAL

SILICONE

STRUCTURAL

SILICONE

1" GLASS

[FIG. 109]

FACE COVER

1" GLASS

1" GLASS

1" GLASS

1" GLASS

1"

GLASS

S.S.G. 90° CORNER

[FIG. 110]

WM

10

WM

10