Step 11) subsill splicing, Includes offset and center-set glazing), Fig. 21 – EFCO 433 Series User Manual

Page 57

June 2012

PART NO. Y017

Page 57 of 90

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

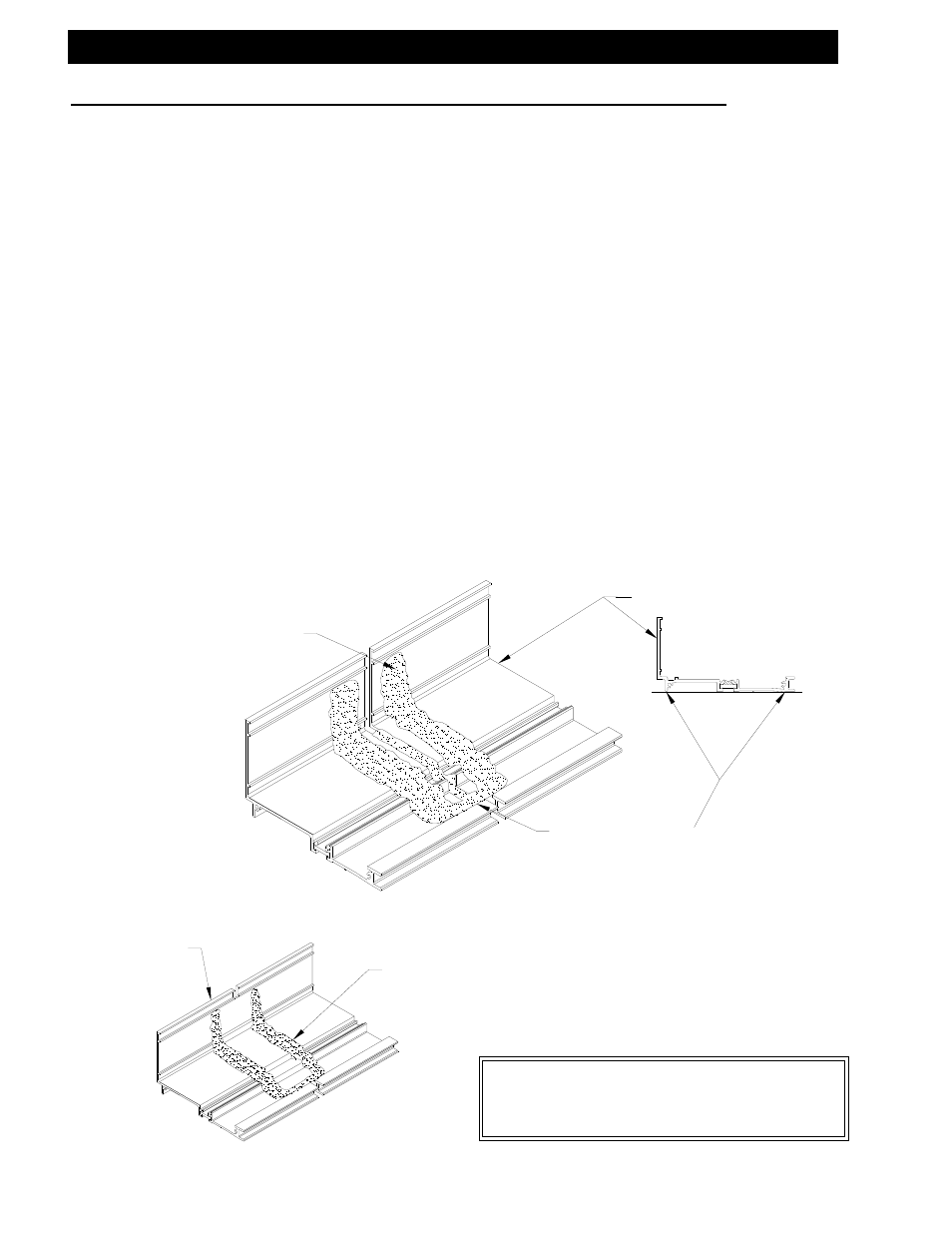

Step 11) Subsill Splicing

Verify that the subsill has been installed according to the instructions on pages 45

through 52. Splice areas are to be centered at a vertical mullion only. Maximum subsill

length between splices is 20’ to 25’. If a splice is required, leave a 1/4" gap between

the subsill ends at the splice area. Install and anchor the next run of subsill. Use a

silicone type sealant and a strip of WM01, bond breaker tape 1 7/8", wide and

approximately 7 1/2" long to create the splice material. Apply silicone to both sides of

the subsill ends and fill the void between the subsills as shown in Figure 21. Ensure

that the bond breaker tape is centered over the 1/4" gap, and set the bond breaker

tape into the sealant. Tool the silicone over the bond breaker tape to create a

watertight seal. If more sealant is required to cover the bond breaker tape, apply the

required amount. Ensure that the splice joint does not interfere with the anchor legs of

the sill and subsill. Making sure that the splice joint is located at the center of the

vertical mullions does this. Refer to the shop drawings or architectural drawings for

mullion centerlines.

AFTER INSTALLING THE BOND

BREAKER TAPE, TOOL THE

SEALANT OVER THE EDGE OF

THE TAPE TO PRODUCE A

WATERTIGHT SEAL.

FILL VOID BETWEEN

SUBSILLS WITH A SILICONE

TYPE SEALANT FROM THE

INTERIOR LEG TO THE BACK

OF THE EXTERIOR LEG.

AFTER THE SPLICE IS INSTALLED, APPLY A

COSMETIC SEAL TO THE INTERIOR GAP,

VERTICALLY UP THE SUBSILL SPLICE.

APPLY SILICONE TYPE SEALANT TO

CREATE A THIN BED TO SET THE

BOND BREAKER TAPE INTO.

[FIG. 21]

SUBSILL

2S44

SUBSILL

2S44

2S44 Shown

4471 Similar