Corners, Fig. 22, Step 12) subsill corner miter and splicing – EFCO 433 Series User Manual

Page 58: Includes offset and center-set glazing)

June 2012

PART NO. Y017

Page 58 of 90

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

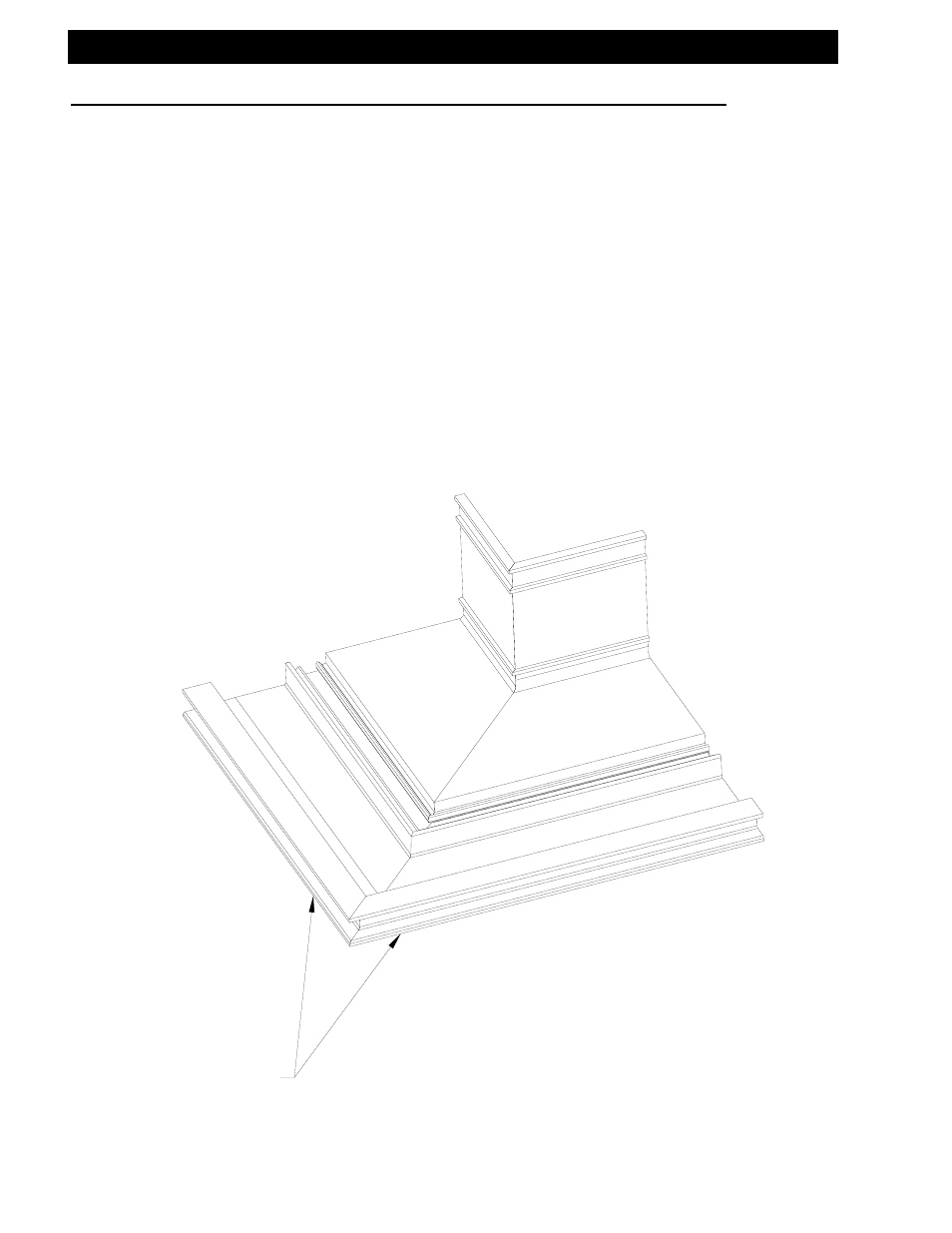

Step 12) Subsill Corner Miter and Splicing

When mitering the subsill for corner applications, cut the subsill material at the

appropriate angle required to form the correct corner. Install the subsill by following

the previous subsill installation instructions. Once the subsill is installed and a tight

miter joint is achieved, use the instructions on page 53 for creating a splice joint seal.

Follow the instructions for sealing a standard splice joint except there should be no gap

between the ends of the mitered subsills. Ensure that the bond breaker tape and

sealant used to create the seal are smooth, so they do not interfere with the anchor

legs on the sill and subsill. If a 90° SSG mullion is used, the bond breaker tape should

be 1-1/2" wide because the corner mullion is 1-3/4" wide.

[FIG. 22]

SUBSILL

2S44

2S44 Shown

4471 Similar