Corner identification and assembly, Includes offset and center-set glazing) – EFCO 433 Series User Manual

Page 59

June 2012

PART NO. Y017

Page 59 of 90

Series 433 Triple Set Installation Instructions

SECTION VII: Corners

(Includes Offset and Center-Set Glazing)

Corner Identification and Assembly

Proper identification of the required corner members is necessary to ensure a timely

installation process. See details of each corner variation on pages 55 through 57 in

Figures 23 through 33.

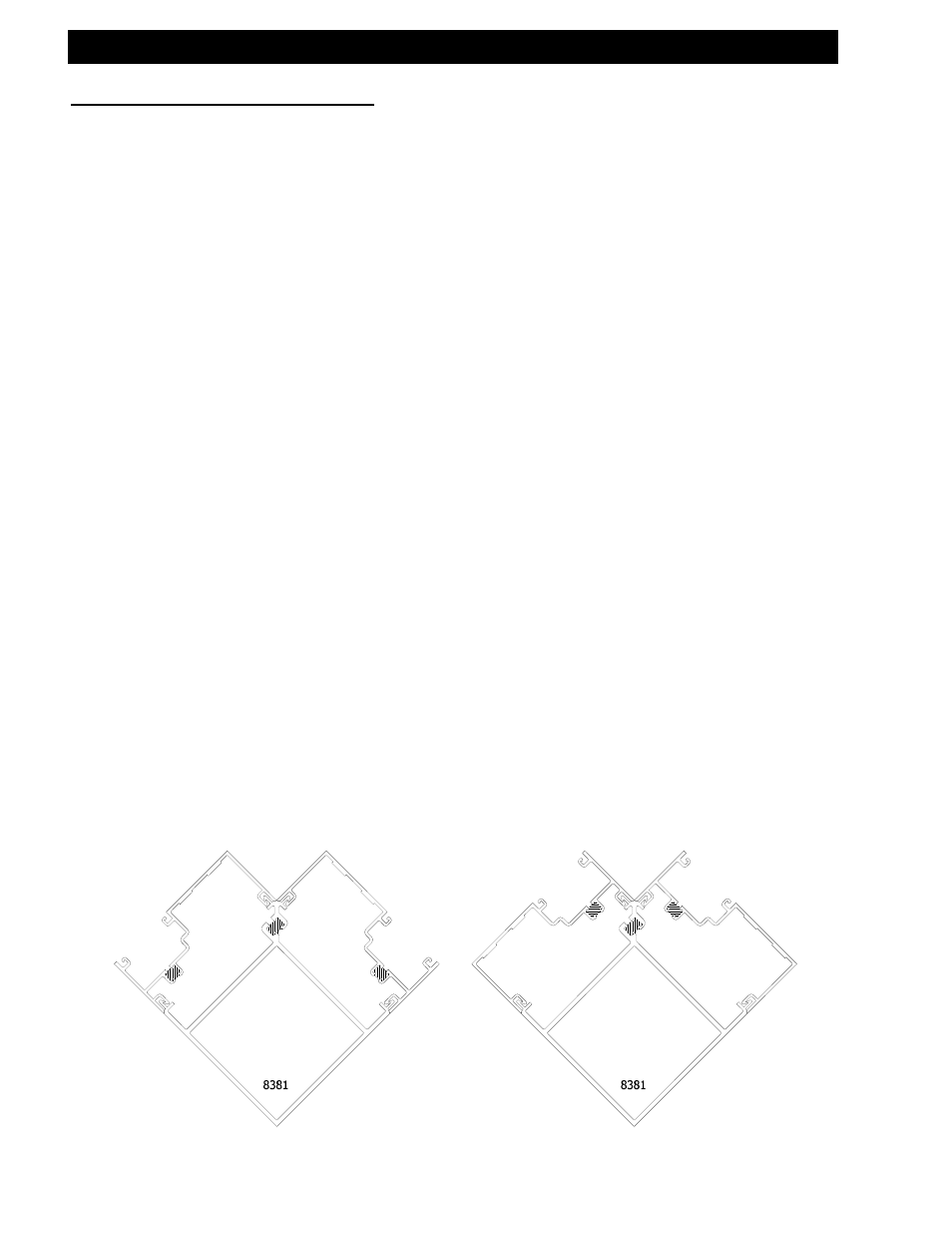

23) 90° outside set corner 27) 135° outside set corner

24) 90° inside set corner 28) 135° inside set corner

25) 90° center-set corner 29) 135° center-set corner

26) 90° multiple glass plane corner 30) 135° multiple glass plane corner

31) 90° outside set SSG corner

Both inside and outside corners can be accommodated with these details.

Figures 32 and 33 on page 61 show typical inside corners.

Determine that the subsill has been installed according to the instructions listed on

pages 46-51. Ensure the adjacent ladders are built with the appropriate mullion half to

be used with the corner mullion. Install the corner member into the subsill. It may be

necessary to temporarily brace the vertical corner member until the adjacent ladders

are installed and anchored. Install and snap one corner ladder completely, and then

install and snap the other onto the corner mullion.

If door openings are required on a run that incorporates a corner member, begin at the

doorframe and assemble towards the corner area with the required ladders.

Unassembled corner extrusions must be attached to the ladders, and the corner

member must be assembled after installation of both adjacent ladders.

[FIG. 23]

[FIG. 24]