Step 9) subsill anchor seal, Step 10) subsill perimeter seal, Includes offset and center-set glazing) – EFCO 433 Series User Manual

Page 56: Fig. 19, Fig. 20

June 2012

PART NO. Y017

Page 56 of 90

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

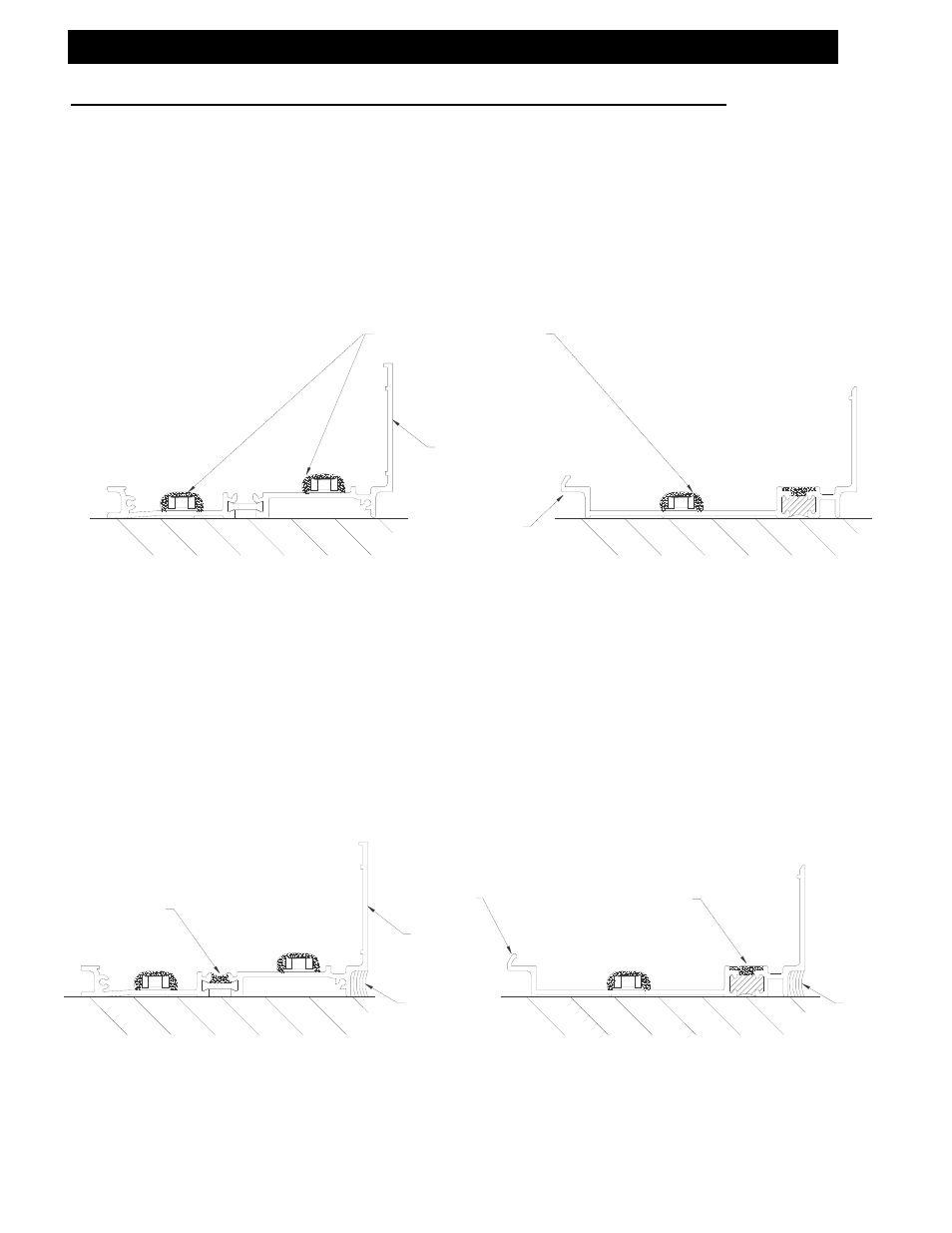

Step 9) Subsill Anchor Seal

The subsill anchors must be sealed with a silicone type sealant. To ensure a good seal,

tool the sealant onto the fastener and surrounding metal. If HD anchors are used,

ensure that the anchor angle and fasteners are sealed also. This procedure should be

followed immediately after anchor installation so it is not forgotten.

Step 10) Subsill Perimeter Seal

The subsill interior should be sealed with a silicone type sealant. Apply sealant and tool

the sealant to ensure a good seal. Clean off all excess sealant. At this time, use a

silicone type sealant to seal the thermal break area as shown in Figure 20. Tool the

sealants into the thermal break area, and ensure that sealant is smooth and flat with

the subsill surface. This procedure should be done prior to installation of the framing

system so it is not forgotten.

SUBSILL

4471

SILICONE TYPE SEALANT

SUBSILL

2S44

[FIG. 19]

SUBSILL

4471

SILICONE

TYPE

SEALANT

SILICONE

TYPE

SEALANT

SUBSILL

2S44

[FIG. 20]

SILICONE

TYPE

SEALANT

SILICONE

TYPE

SEALANT