Subsill fabrication & installation, Step 1) cut length, Step 2) end dam installation – EFCO 433 Series User Manual

Page 51: Includes offset and center-set glazing), Series 433 triple set installation instructions

June 2012

PART NO. Y017

Page 51 of 90

Series 433 Triple Set Installation Instructions

SECTION VI: Subsill Fabrication and Installation

(Includes Offset and Center-Set Glazing)

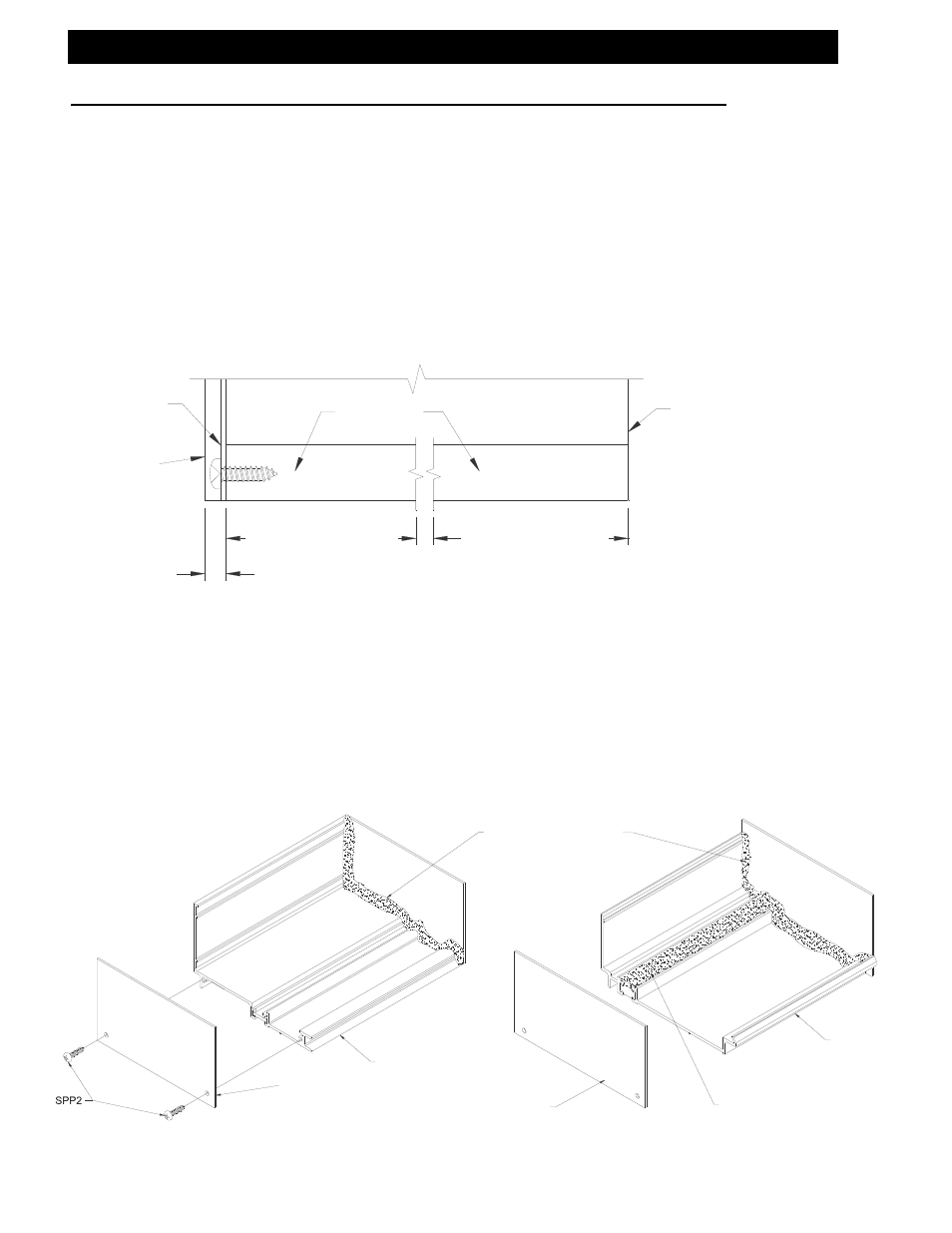

Step 1) Cut Length

Measure the opening to determine the cut length of the subsill. Subtract ¼” for the

width of the end dam and fastener head from the rough opening for each end. Cut the

subsill to the determined length.

If end dams are not required, cut the subsill to the rough opening width.

Step 2) End Dam Installation

The end dam shall be attached to the subsill with 2 SPP2 fasteners on each end. Seal

the end of the subsill with silicone sealant before attaching the end dam to the subsill.

Tool the sealant at the interior joint of the end dam to ensure a good watertight seal.

See Figure 6 below. If end dams are not required, ensure the subsill is tight against

the condition and seal the joint between the subsill and condition similar to Figure 6.

[Fig. 5]

CUT LENGTH = R.O. - 1/2" for end dams (See Figure 5)

CUT LENGTH = R.O. for no end dams (See Figure 5)

+1/8"

- 0"

CUT LENGTH =

ROUGH OPENING

WITHOUT END DAMS

ROUGH

OPENING

3/16"

K941

END DAM

ROUGH

OPENING

SUBSILL 2S44

4471 SIMILAR

CUT LENGTH =

ROUGH OPENING-1/2"

WITH END DAMS

APPLY SEALANT TO THE TOP

OF THE THERMAL CAVITY

ACROSS ENTIRE SUBSILL AND

TOOL SMOOTH

4471

K941 END DAM

FASTENERS WILL

NOT BE USED

K941

END DAM

APPLY SEALANT TO ENDS OF

THE SUBSILL BEFORE

ATTACHING END DAM

TOOL SEALANT AT JOINT

2S44

[Fig. 6]