Great Plains YP4425A Operator Manual User Manual

Page 94

90

YP4425A

Great Plains Manufacturing, Inc.

401-805M

2012-02-23

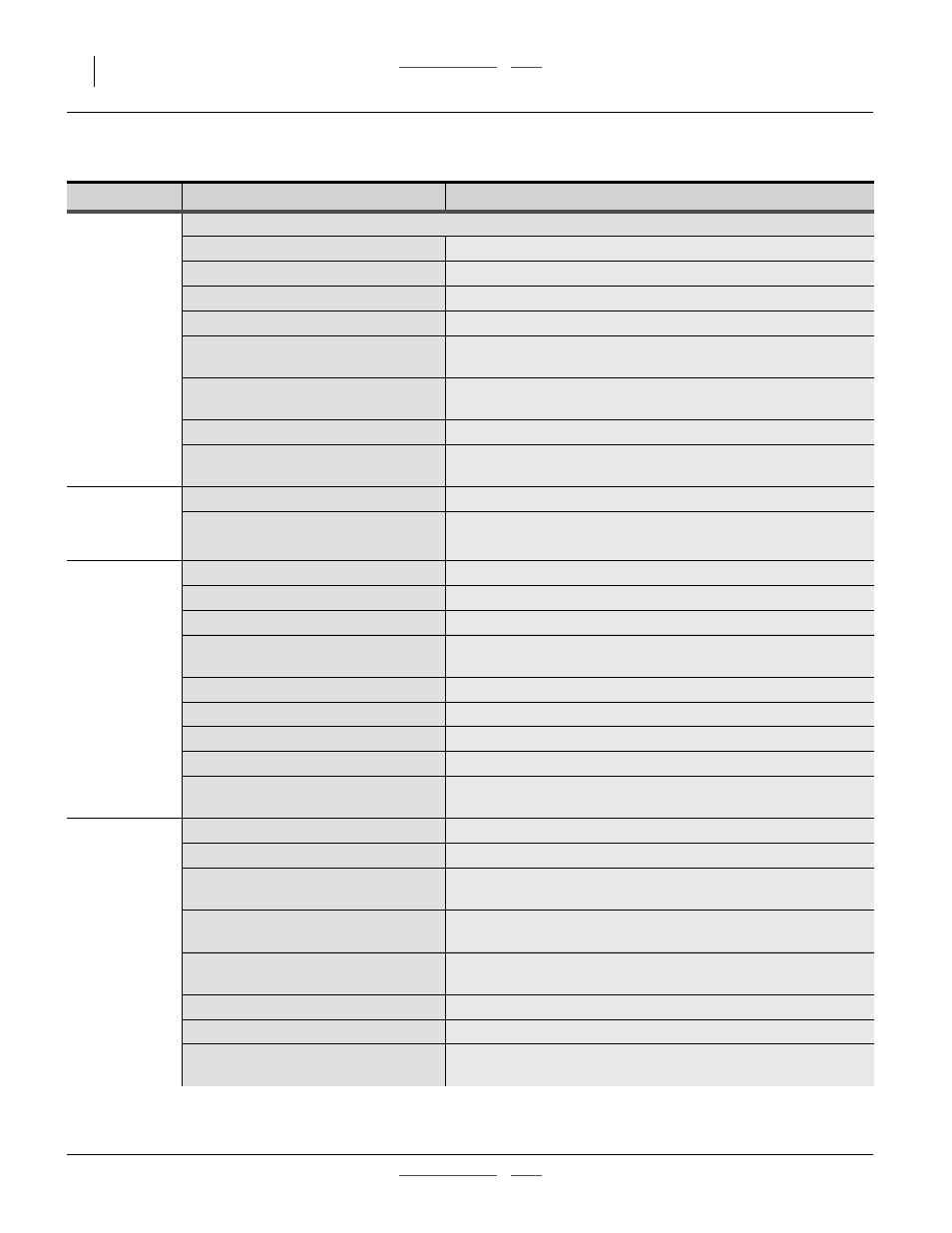

Uneven

seed

spacing

See “Population Troubleshooting Charts” on page 84.

Excessive field speed.

Reduce field speed.

Unclean seed.

Use clean seed.

Damaged seed tube

Inspect; repair or replace.

Seed-Lok

®

plugging.

Lock up Seed-Lok

®

Row-unit discs not turning.

See “Row-unit discs not turning freely” in this

Troubleshooting chart.

Worn/rusted sprockets and/or chain

idler or bearings.

Check and replace any worn/rusted sprockets or chain idlers.

Partially plugged row-unit seed tube. Lift up planter, expose bottom of seed tube and clean out.

Lack of proper seed lubrication on

seed.

See “Seed Lubricant” on page 128.

Planter does

not fold or

unfold fully

Fold cylinders out of phase

Re-phase cylinders, refer to page 30

Air in lines

Bleed fold circuit, refer to page 101

Uneven

seed depth

Excessive field speed.

Reduce field speed.

Planting conditions too wet.

Wait until drier weather.

Incorrect coulter depth setting.

See coulter manual or set unit mounted coulter.

Excessive or improper row unit down

pressure spring setting.

See 25 series row-units, page 67.

Damaged seed tubes.

Check seed tubes for damage.

Seed-Lok

®

building up with dirt.

Lock up Seed-Lok

®

Row-unit not penetrating low spots.

Adjust row-unit, see instructions beginning on page 67.

Rough planting conditions.

Rework the field.

Seed firmer not in place and set to

correct tension.

See “Seed Firmer Adjustments” on page 79.

Press wheel

or row-units

plugging

Planting conditions too wet.

Wait until drier weather.

Too much pressure on row-units.

Reduce down pressure on row-units.

Coulters set too deep, bring up

excess dirt and moisture.

Check coulter adjustment.

Planter not set to run level from front

to rear.

Backed up with planter in the

ground.

Clean out and check for damage.

Failed disc bearings.

Replace disc bearings.

Disc blades worn.

Replace disc blades.

Scraper worn or damaged. Side

depth wheels not set correctly.

Adjust side depth wheels page.

General Troubleshooting

Problem

Cause

Solution