Great Plains YP4425A Operator Manual User Manual

Page 93

Great Plains Manufacturing, Inc.

Troubleshooting

89

2012-02-23

401-805M

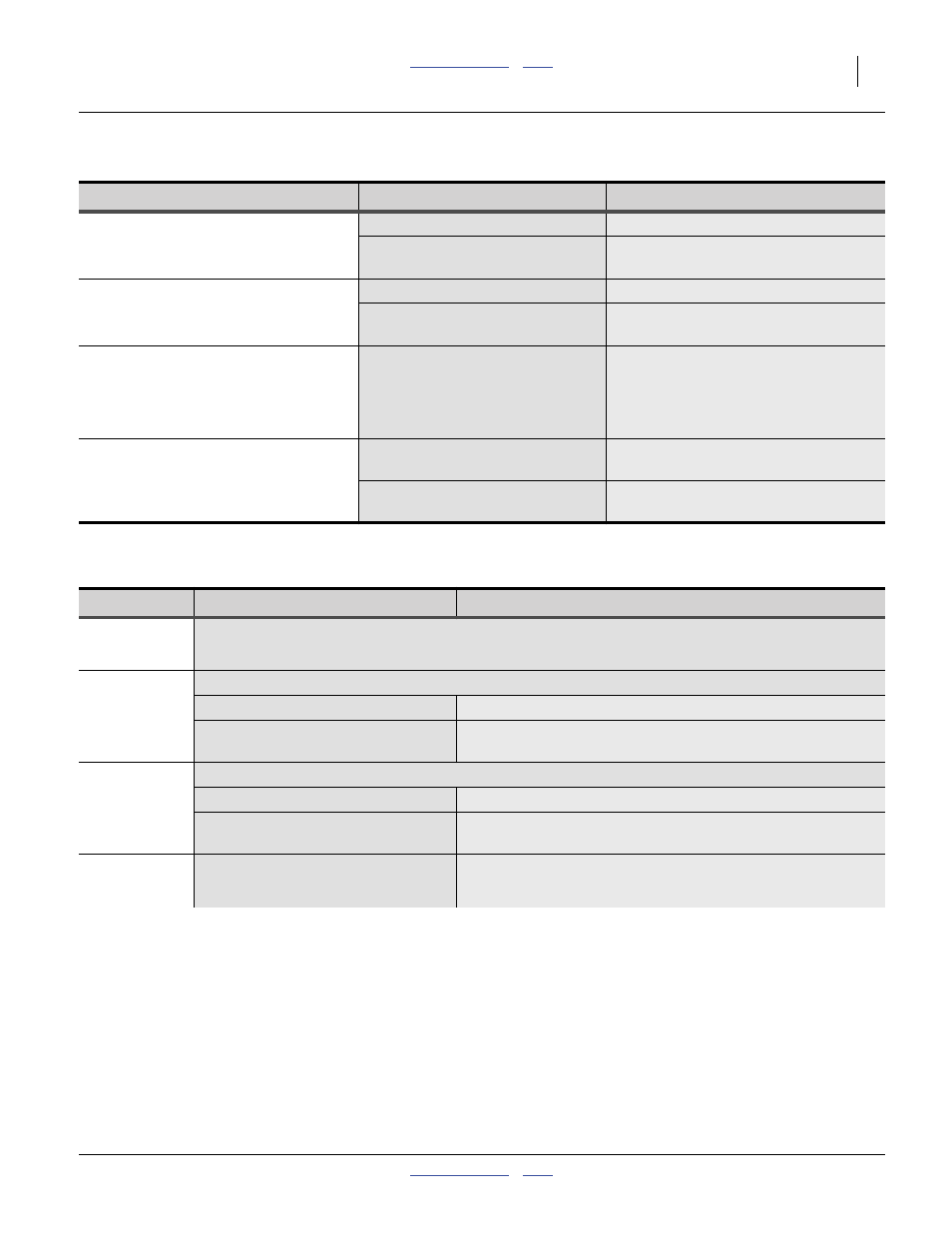

Single or multiple hoses plugging just

ahead of airbox.

Fan speed too high/too low.

Check/adjust fan speed.

Possible air leak.

Check for air leak downstream

between box and top of meter.

All rows fail.

Lack of seed.

Fan speed too high. Adjust fan speed.

Extremely high populations may

require slightly reduced field speed.

1, 2, 3, or more outlets fail.

Outlets can be side-by-side or random.

Plugging may also move from one

outlet to another.

Foreign matter in seed chamber in

bottom of airbox.

Clean out seed chamber.

Little or no seed to a lot of rows with

heavily treated seed.

Seed treatment sticky.

Add Ezee Glide Plus to seed to dry out

seed treatment.

Treatment mixed unevenly and

plugging outlets.

Clean out seed. Re-mix.

Seed Delivery Troubleshooting

Problem

Cause

Solution

General Troubleshooting

Problem

Cause

Solution

Population

Alarms

See “Population Troubleshooting Charts” on page 84.

Excess Seed

Remaining

See “Population Troubleshooting Charts” on page 84.

Field size different.

After ruling out population problems, re-check geography.

Excessive gaps between planter

passes.

Adjust marker, page 150.

Seed

Consumptio

n Too High

See “Population Troubleshooting Charts” on page 84.

Field size different.

After ruling out population problems, re-check geography.

Excessive overlap.

Irregular shaped field.

Adjust marker, page 150.

Rows Not

Planted

If not detected by seed monitor,

check for plugged row-unit seed tube

Lift planter, expose bottom of seed tube and clean out.