Adjusting gauge wheel scrapers, Refer to figure 90 – Great Plains YP4425A Operator Manual User Manual

Page 78

74

YP4425A

Great Plains Manufacturing, Inc.

401-805M

2012-02-23

• If wheel does not fall freely, loosen hex-head bolt

and slide wheel arm out just until wheel and arm move

freely. Retighten hex-head bolt

according to grade:

1

⁄

2

inch Grade 5 bolt, 75 foot-pounds (102 N-m).

1

⁄

2

inch Grade 8 bolt, 110 foot-pounds (149 N-m).

Note: Use “Torque Values Chart” on page 135 for

reference.

6.

Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied,

tighten pivot bolt

to 110 foot-pounds (149 N-m).

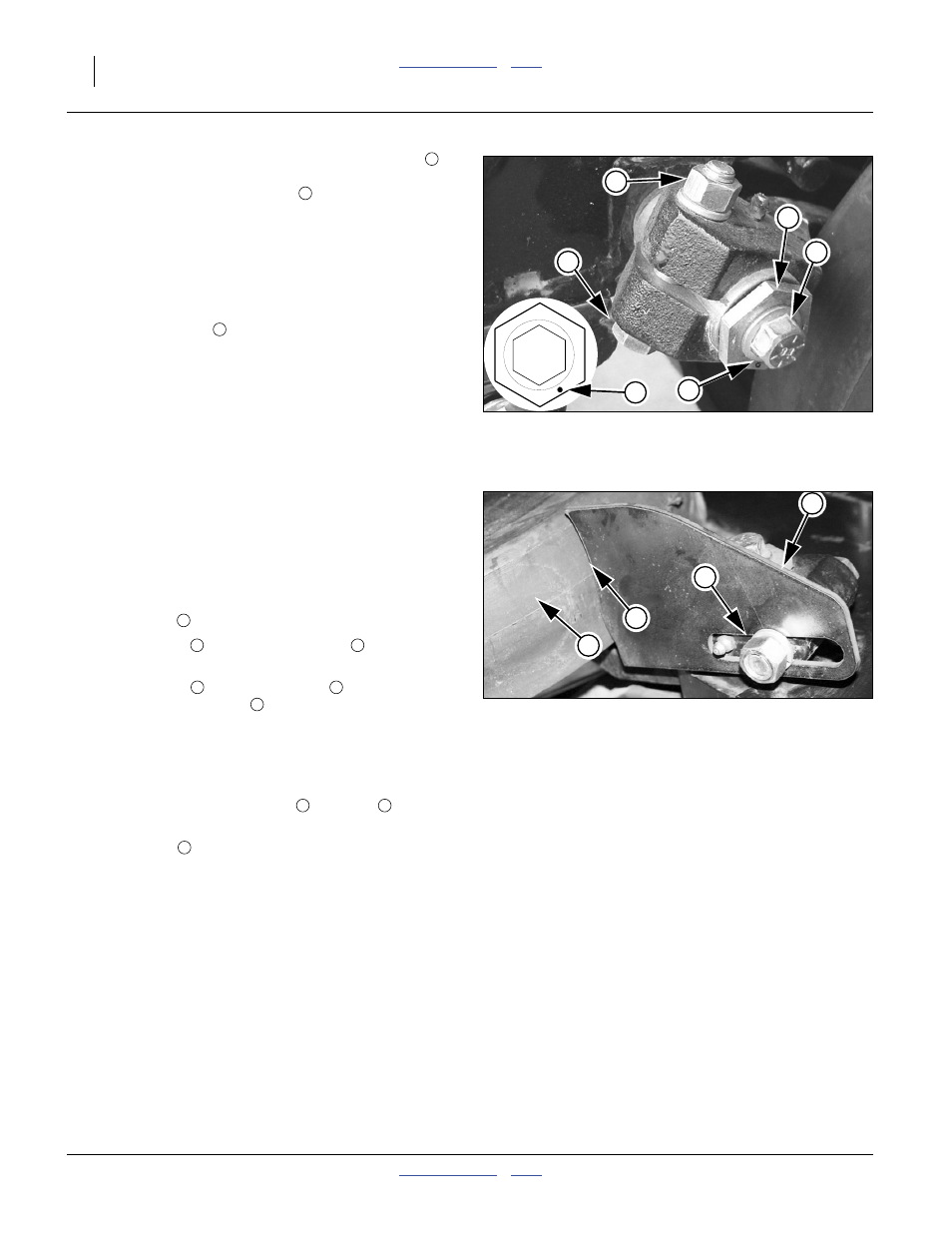

Adjusting Gauge Wheel Scrapers

Refer to Figure 91 (bottom view)

Scrapers are optional, and may be useful in moist or

sticky soils that tend to accumulate on gauge wheels and

reduce intended planting depth.

To adjust scrapers:

1.

Loosen nut

2.

Slide scraper

toward gauge wheel

until scraper

touches tire.

3.

Slide scraper

away from wheel

leaving a

1

⁄

8

inch (3 mm) gap at

.

4.

Rotate scraper left and right around bolt, making

sure it cannot touch tire if bumped in field. If it can

touch tire, back scraper away from wheel until it

cannot.

5.

Center scraper angle on bolt

constant.

6.

Tighten nut

Starting Point

Figure 90

Disc/Gauge Wheel Adjustment

22524

22525

2

1

4

4

1

Figure 91

Gauge Wheel Scraper

25273

8

5

6

7

8

5

7