Great Plains YP4425A Operator Manual User Manual

Page 92

88

YP4425A

Great Plains Manufacturing, Inc.

401-805M

2012-02-23

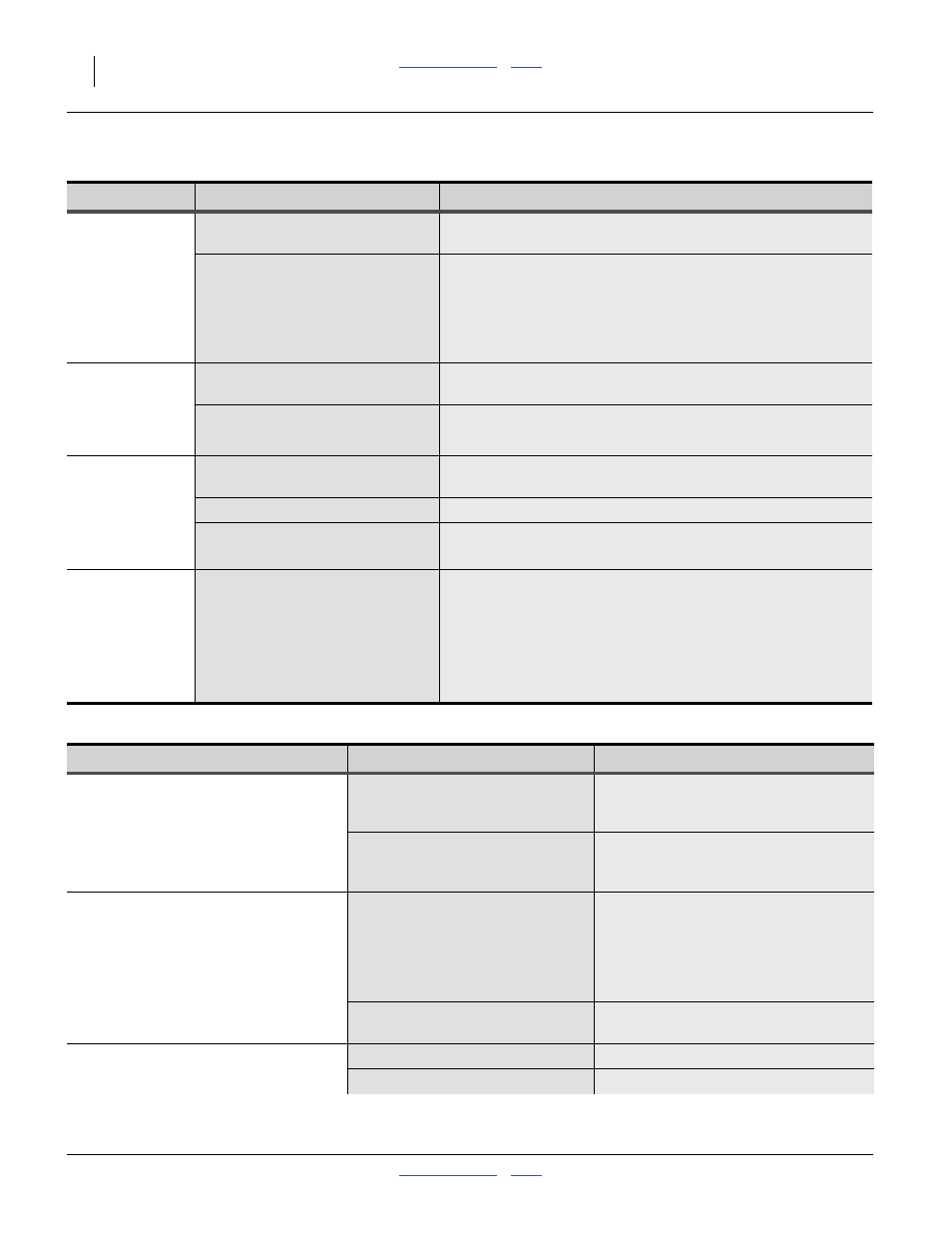

Skips and

Bare Spots

After Turns

Fan was turned off at turns

Leave fan running. Meter Pressurization must be maintained

during turns, or seed will fall out of disc pockets.

Insufficient hydraulic flow to keep

fan running at speed required to

maintain meter pressurization

Check tractor capability against requirements (page 134).

If sufficient:

• Fold markers before engaging lift.

• Use a less aggressive lift rate.

• Monitor fan rpm during end-of-pass operations.

Unable to

adjust air

pressure low

enough.

Lower limit reached in

DICKEY-john

®

software.

At User Level 2, reduce the controlled air lower limit in the

software.

Fan speed too high, vane rotated

to maximum.

Reduce the fan speed.

Seed too

shallow or

scattered on

ground from a

single row

Bottom of seed tube damaged.

Replace seed tube. Avoid setting planter straight down. Use

forward motion when lowering.

Row not penetrating in tire tracks. Increase down force on parallel arm springs.

Opener depth too shallow.

Change side depth wheel setting.

System is

unable to

automatically

control air

meter

pressure.

Signal from air pressure sensor

lost. (failed sensor or wiring)

Air pressure may be controlled manually, consult

DICKEY-john

®

Planter/Drill Control manual, User Level 2/3.

Population Related

Problem

Cause

Solution

Seed Delivery Troubleshooting

Problem

Cause

Solution

Single row doesn’t fill or keep up with

other rows.

Y tube is bent/angled off feed

pipe.

Loosen pipe and spin so the bend is

straight down and Y-tube is not

pointing to front or rear of air pipe.

Drop tube to meter is too long,

causing seed to pool and plug

hose or Y-tube.

Shorten hose (with planter raised, but

row units lowered, to ensure hose is

not too short).

Both rows on one meter outlet low or

not keeping up with other rows.

Blockage in air slot in top of

airbox.

Clear by using a long skinny tool and

taking hose off through hose outlet.

It may be necessary to take top off

airbox or use side access doors to

clear junk from slot.

Bad hose routing between

delivery hose and airbox on wing.

Correct hose routing.

Multiple rows fail for lack of seed.

Fan speed too high/too low.

Check/adjust fan speed.

Out of seed.

Add seed.