Marker adjustments, Marker disc adjustment – Great Plains YP4425A Operator Manual User Manual

Page 63

Great Plains Manufacturing, Inc.

Adjustments

59

2012-02-23

401-805M

Marker Adjustments

There are three adjustments and two maintenance items

for markers:

• Disc Angle (following)

Even if your row spacing rarely changes, you may

need to adjust disc angle for soil conditions and

planting speed.

• Shear Bolt Replacement (Maintenance, page 103)

If a marker hangs up on an obstruction, a bolt at the

fold is designed to fail.

• Marker Cylinder Bleed (Maintenance, page 103)

If marker operation is irregular, check that system is

not contaminated with air.

• Marker Extension (Initial Setup, page 150)

Once set for a specific row spacing, this only needs

periodic checking to ensure the clamp is secure.

• Marker Speed (Initial Setup, page 149)

Once initially set by your dealer, this rarely needs

modification.

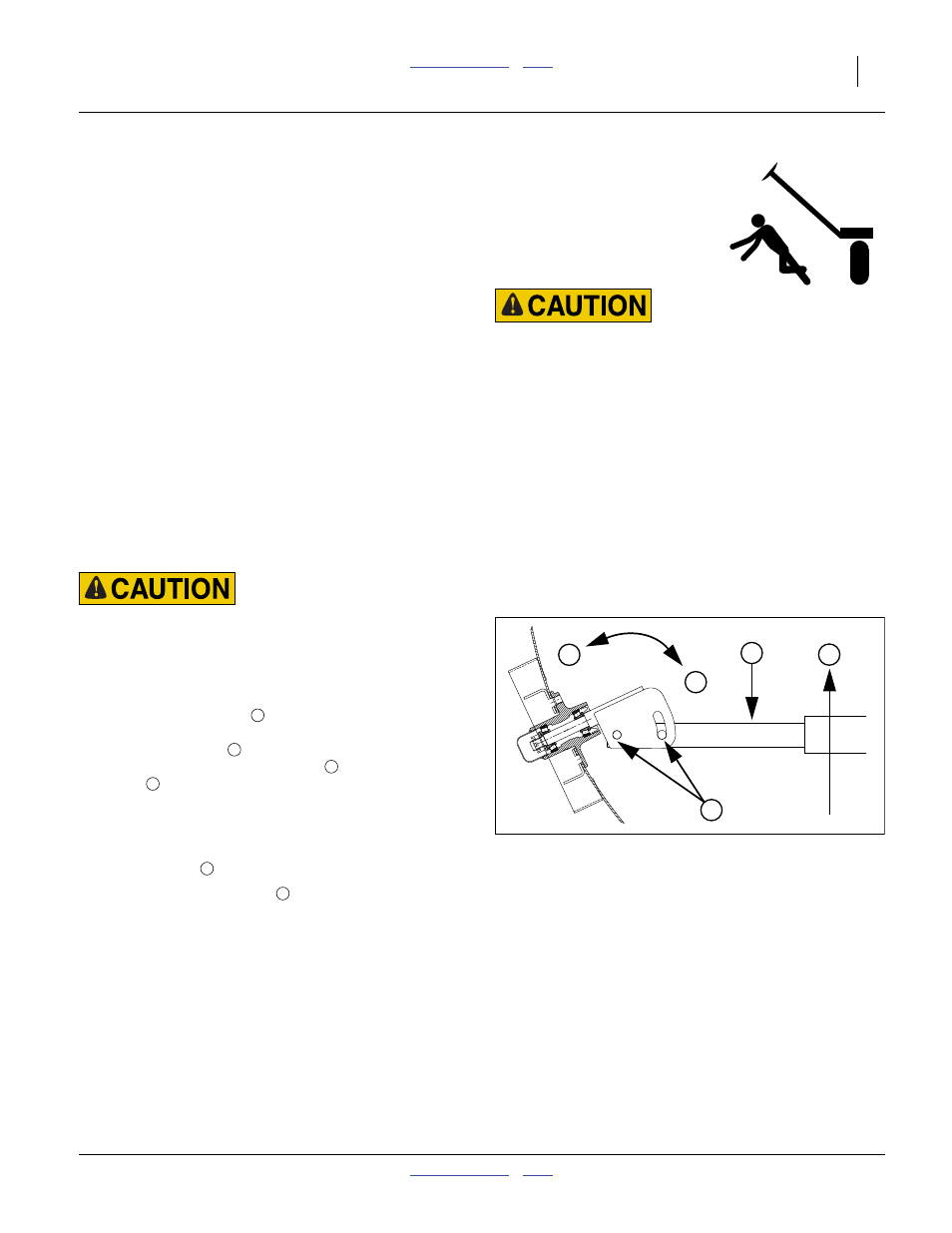

Marker Disc Adjustment

Sharp Object Hazard:

Use caution when making adjustments in this area. Marker

discs may be sharp.

To change angle of cut, and the width of the mark,

loosen

1

⁄

2

-inch bolts

holding the disc assembly.

For a wider mark

, increase the angle of the

marker with respect to the tube

. For a narrower

mark

, reduce the angle.

Note: Do not set a marker angle wider than need to make

a useful mark. Excess angle increases wear on all

marker components.

2.

Tighten bolts

Note: The direction of travel

tends to drive the disc

angle to Wide. If bolts are not tight enough, or

loosen over time, the disc will slip into the Wide

mark configuration.

Overhead Sudden Marker Movement Hazard:

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the planter when folding or

unfolding the markers.

Figure 65

Marker Disc Angle

11757

2

1

N

W

T

1

T