Press wheel adjustment, Press wheel down pressure, Press wheel stagger – Great Plains YP4425A Operator Manual User Manual

Page 84: Press wheel down pressure press wheel stagger

80

YP4425A

Great Plains Manufacturing, Inc.

401-805M

2012-02-23

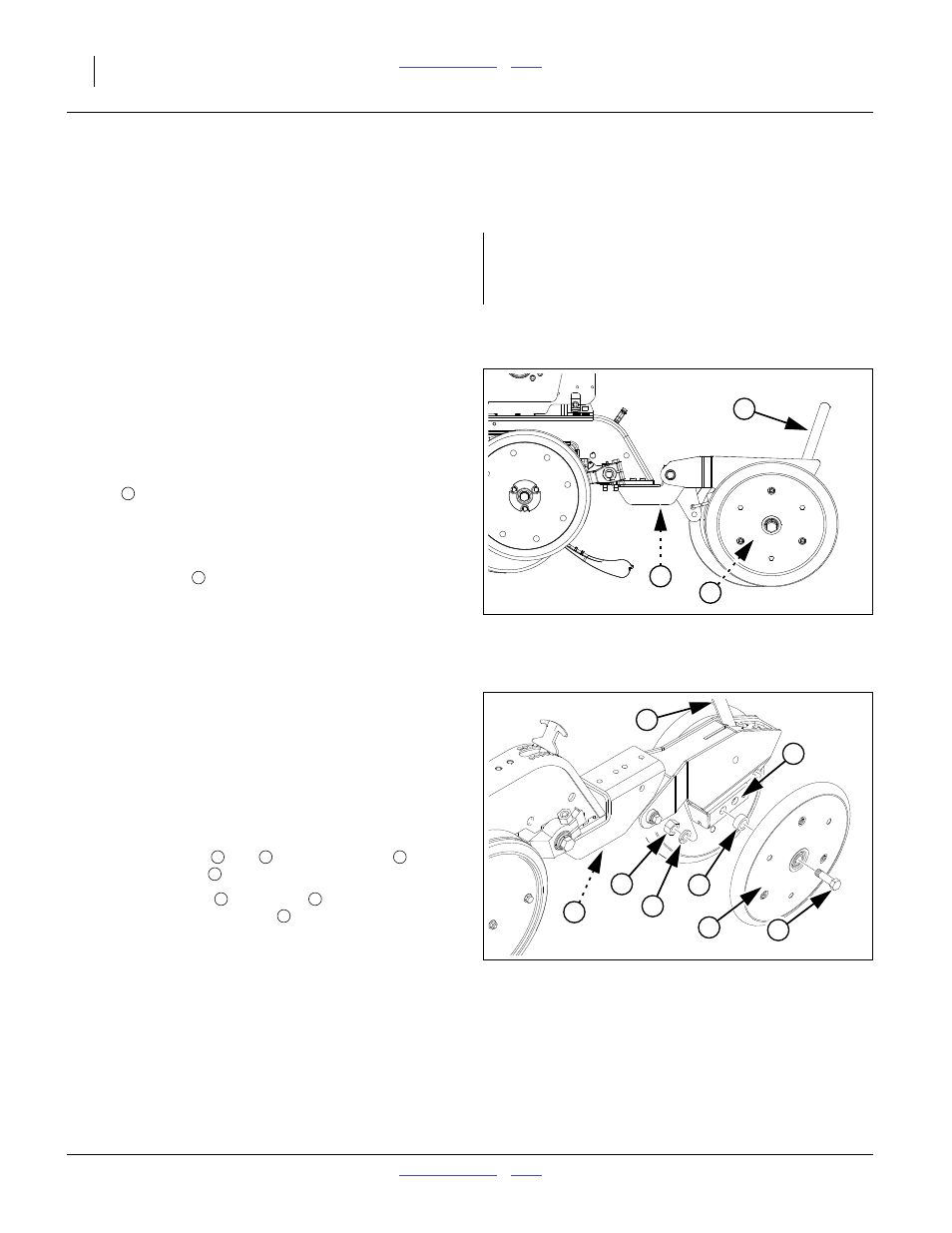

Press Wheel Adjustment

The press wheels close the furrow which gently presses

the soil over the seed to ensure good seed-to-soil

contact for even emergence.

To provide consistent seed firming, the press wheels are

free to move downward from their normal operating

position. This system maintains closing/pressing action

even if the row unit arm is lifted when the discs encounter

obstructions.

There are three adjustments available on the press

wheel assembly:

Down pressure (shown at maximum)

2.

Wheel stagger (shown staggered)

3.

Centering (see Figure 105 on page 81)

Press Wheel Down Pressure

Handle

sets down pressure, which may need

adjustment for different soil types and field conditions.

• Relax the handle forward (in the direction of travel) for

decreased down pressure.

• Pull the handle

back for increased down pressure.

Note: Higher press wheel down pressures reduce the

down force on the main row unit shank

components, such as the openers. High press

wheel settings may require an increase in overall

row unit down force. See page 67.

Press Wheel Stagger

The factory stagger setting has been found optimal for

residue flow. If your conditions appear to require even

press wheels, you might try one row before

re-configuring the entire planter. To change the stagger:

Raise the planter and install the lift assist cylinder

locks. See “Lift Cylinder Lock-Up” on page 27.

2.

Remove the bolt

, nut

and lock-washer

for the

left press wheel

.

3.

Move the spacer

and wheel

to the forward of

the two mounting holes at

.

4.

Re-install the bolt, lock washer and nut. Tighten.

Higher press wheel down pressures reduce the down

force on the main row unit shank components, such as

the openers. High press wheel settings may require an

increase in overall row unit down force. See page 67.

Figure 103

Press Wheel Adjustments

25118

Figure 104

Press Wheel Force & Stagger

22907

1

8

7

6

5

3

4

2

4

5

6

8

7

8

2