Adjustments – Great Plains 2510HDP Operator Manual User Manual

Page 38

118-245M

2013-10-21

34

1510HDP/2010HDP/2510HDP

Great Plains Manufacturing, Inc.

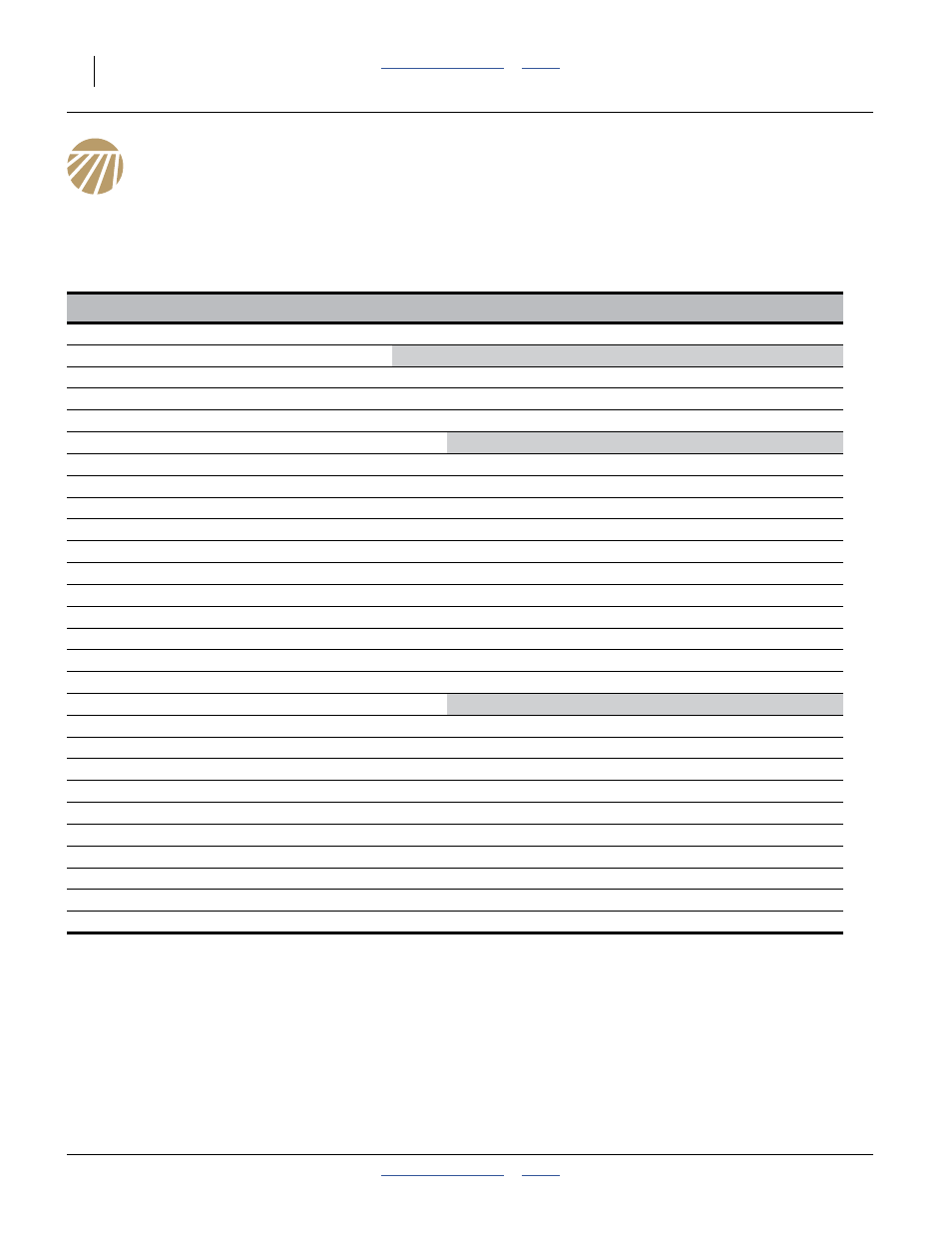

Adjustments

To get full performance from your drill, you need an

understanding of all component operations, and many

provide adjustments for optimal field results.

Even if your planting conditions and rates rarely change,

some of these adjustment items need periodic attention

due to normal wear.

Adjustment

Page

The Adjustment Affects

Consistent control of seeding depth

Pass alignments with no overlap or excessive gap

Visibility of mark for next pass

Efficient marker operation at turns

Seed population

Hydraulic Drive Rate

Control of seed rate for entire drill

Coarse control of seed rate at a main box

Fine control of seed rate at a main box

Precise control of main box seed rate

Small seed population

Tuning small seed rate for your specific seed

Material application rate

Quicker closure on a rate calibration

Tuning application rate for your specific material

Seed Monitor Adjustments

-

See separate DICKEY-john manual

Unit-Mounted Coulter Adjustments

Depth of groove ahead of opener furrow

Consistent seeding depth in tire tracks

Consistent seeding depth

Alternate row spacings and calibration

Required meter for seed type

Changing Precision Seed Wheels

Alternate seeds and available rates within a single seed

Consistent metering

Optimal seed-to-seed spacing in twin-row

Reliable seed placement at furrow bottom

Opener Depth (Press Wheel Height)

Seeding depth