Great Plains 2510HDP Operator Manual User Manual

Page 105

Great Plains Manufacturing, Inc.

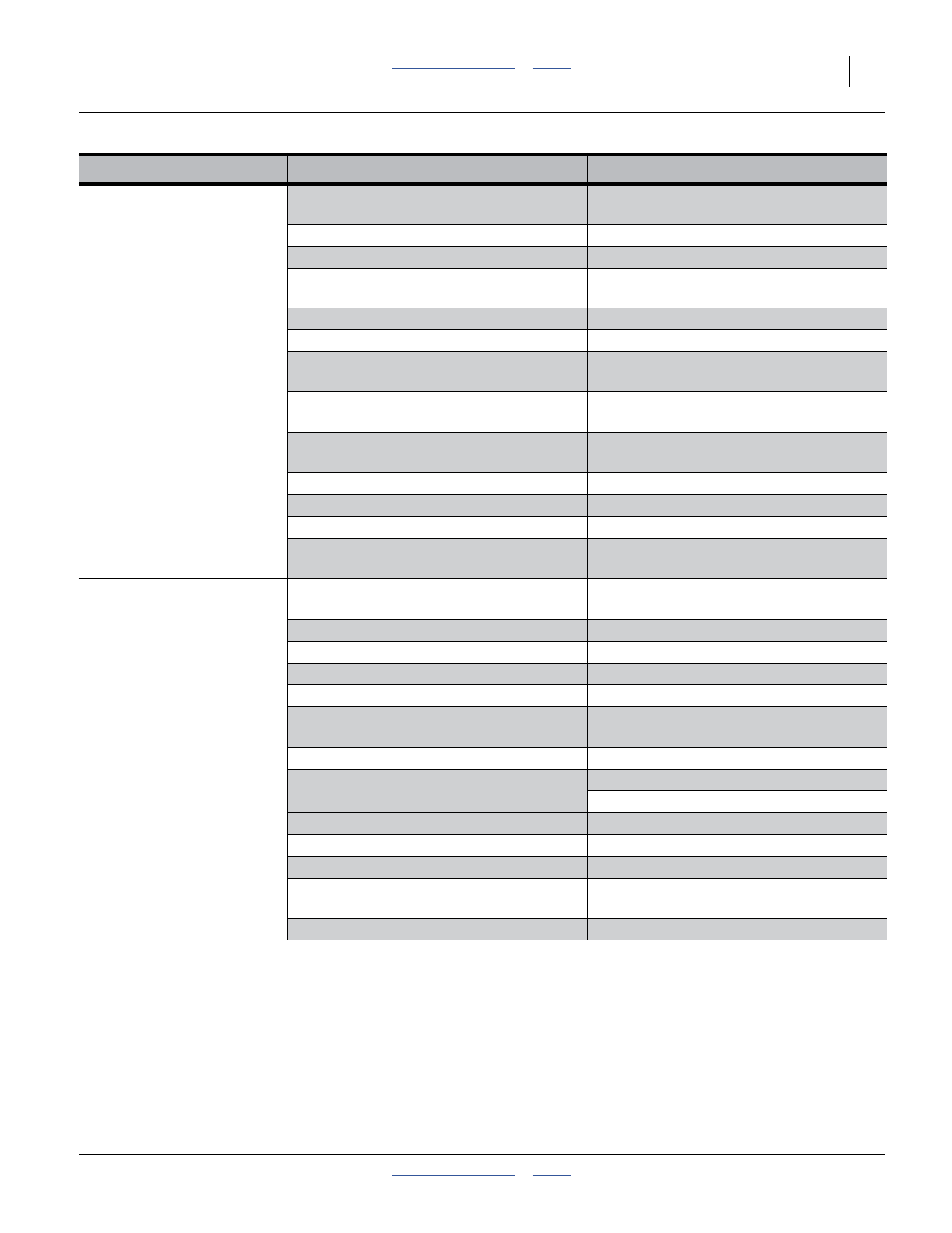

Troubleshooting

101

2013-10-21

118-245M

Uneven seed spacing

Excessive field speed.

Slow down. Check Seeding Rate Chart for

correct maximum field speed.

Unclean seed.

Use clean seed.

Lack of proper seed lubrication on seed.

See “Seed Lubricants” on page 29.

Build up of seed treatment in meter.

Clean out seed meter, page 106. Add

more talc lubricant.

Seed-Lok™ plugging.

Damaged or missing seed flap.

Replace seed flap.

Opener disks not turning.

See “Opener disks not turning freely” in

this Troubleshooting chart.

Plugged opener seed tube.

Raise drill, expose bottom of seed tube

and clean out.

Worn/rusted sprockets and/or chain idler.

Check and replace any worn/rusted

sprockets or chain idlers.

Seed meter wheel damaged or worn.

Check seed meter wheel and replace.

Seed meter slide worn.

Replace seed meter slide, page 106.

Plugged sliding seed tube.

Clean out sliding seed tube.

Incorrect seed meter wheel for seed size.

Verify seed count on seed bag with seed

meter wheel.

Uneven seed depth

Excessive field speed.

Slow down. Check Seeding Rate Chart for

correct maximum field speed.

Coulter depth adjustment

Check hitch operator’s manual.

Planting conditions too wet.

Wait until drier weather.

Drill frame height incorrect.

Check drill frame height, page 18.

Drill not level front-to-back in field.

Readjust top link to level drill.

Opener press wheel spring force is set too

high.

Check press wheel adjustments, page 65.

Incorrect spring pressure on openers.

Correct spring pressure, page 51.

Seed-Lok™ building up with dirt.

Engage Seed-Lok™ only in dry conditions

Damaged or missing seed flaps.

Replace seed flaps.

Damaged opener seed tube.

Check disk spreader, page 111.

Row-unit not penetrating low spots.

See “Row Unit Down-Force” on page 51.

Partially plugged opener seed tube.

Raise drill, expose bottom of seed tube

and clean out.

Incorrect choice of coulter.

See hitch operator’s manual.

Problem

Cause

Solution