Leveling: dual-wheel – Great Plains 2510HDP Operator Manual User Manual

Page 25

Great Plains Manufacturing, Inc.

Preparation and Setup

21

2013-10-21

118-245M

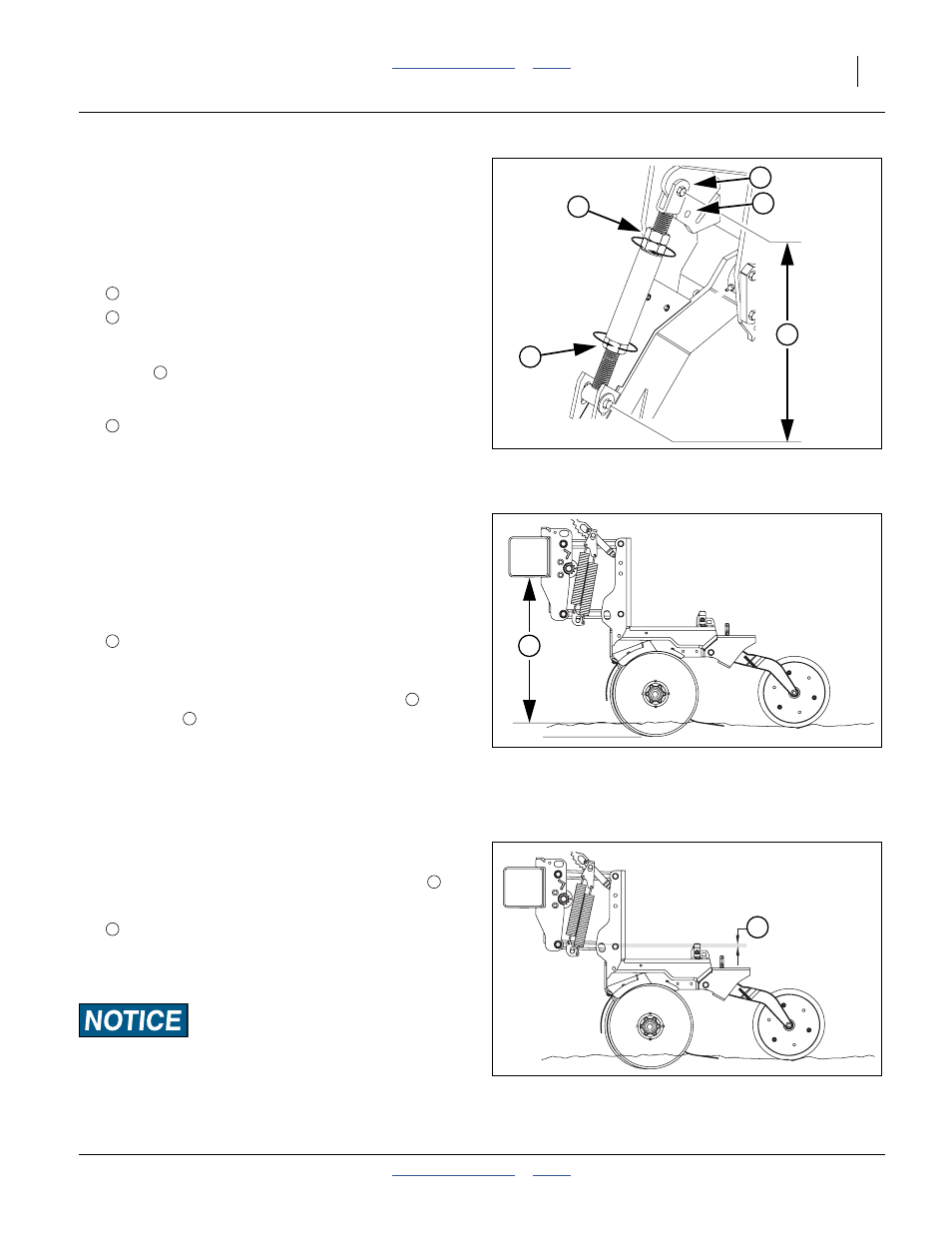

Leveling: Dual-Wheel

Refer to Figure 16

1.

If operations are being changed between

non-bedded and bedded planting, set the spring

turnbuckle clevis position before checking length and

opener height.

2.

Check the link length. The factory setting for link

length

, measured at centerlines, is:

3.

Lower the drill in representative field conditions and

set the 3-point hitch circuit to Float.

Refer to Figure 17

Note: This presumes a planting depth of 1.75in (44mm).

If your depth is different, re-adjust the tool bar

height when adjusting the press-wheel (page 65).

4.

Initially adjust drill distance between bottom of

opener tool bar and planting ground:

Refer to Figure 16

5.

To adjust turnbuckle length, loosen jam nut

. Turn

turnbuckle

to shorten or lengthen as necessary.

When adjusting the turnbuckle length, remember:

+ Lengthening turnbuckle raises drill.

- Shortening turnbuckle lowers drill.

Re-tighten jam nut when height is final.

6.

Level drill with top three-point link.

Refer to Figure 18

7.

Level drill with top of three-point link. Adjust so that

row units are inclined slightly uphill, measured

at

the ends of the parallel arms:

The 1in/2.5cm dimension shown is a general dimension

that varies with planting conditions.

Ensure the opener mount is running higher than the opener

body. This ensures ample reserve for opener upfloat if the

opener strikes a rock or other object.

Lower hole

Bedded planting

Upper hole

Non-Bedded planting

Non-Bedded

Bedded

17

1

⁄

2

in (44.5cm)

20

3

⁄

4

in (52.7cm)

Tool bar height

26in (66cm)

Arm inclination

1in (2.5cm) maximum

Figure 16

Dual-Wheel Turnbuckle

22845

3

1

2

5

6

1

2

3

3

Figure 17

Dual-Wheel Height

24050

4

4

5

6

Figure 18

Dual-Wheel Opener Level

24047

7

7

7